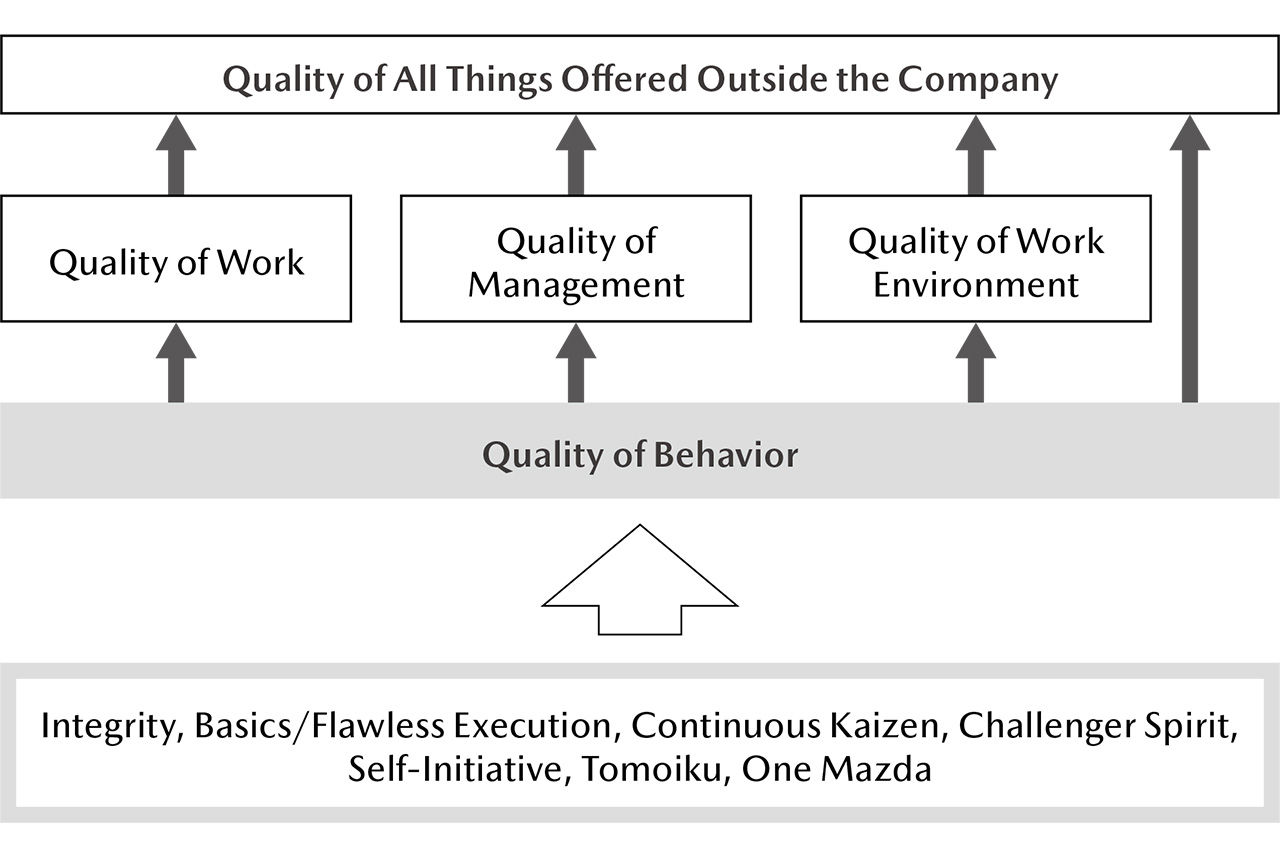

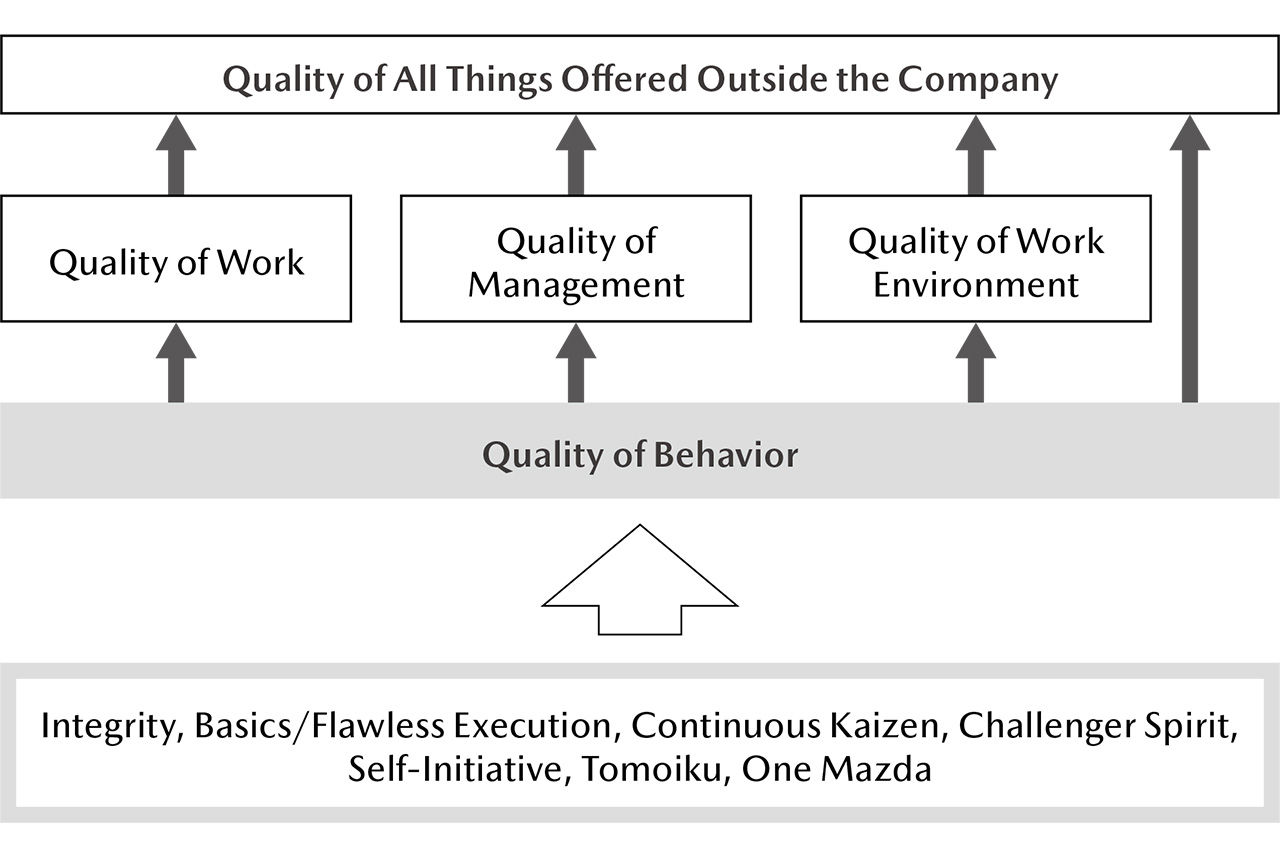

Mazda believes that it is important to enhance the quality of its products, services, and all other things offered outside the Company to satisfy customers and to exercise its corporate philosophy. The Company has defined the Five Types of Mazda Quality: quality of behavior, quality of work, quality of management, quality of work environment, and quality of all things offered outside the Company, which is underpinned by the preceding four. In line with its quality policy, the Company continues to evolve its initiatives and promote close coordination among all areas of operation to further enhance Mazda's unique value.

QUALITY

Basic Approach

Mazda Quality Policy

To enrich the lives of our customers by providing products and services that reflect steady and uncompromising work

Five Types of Mazda Quality

Approach Toward Quality Assurance

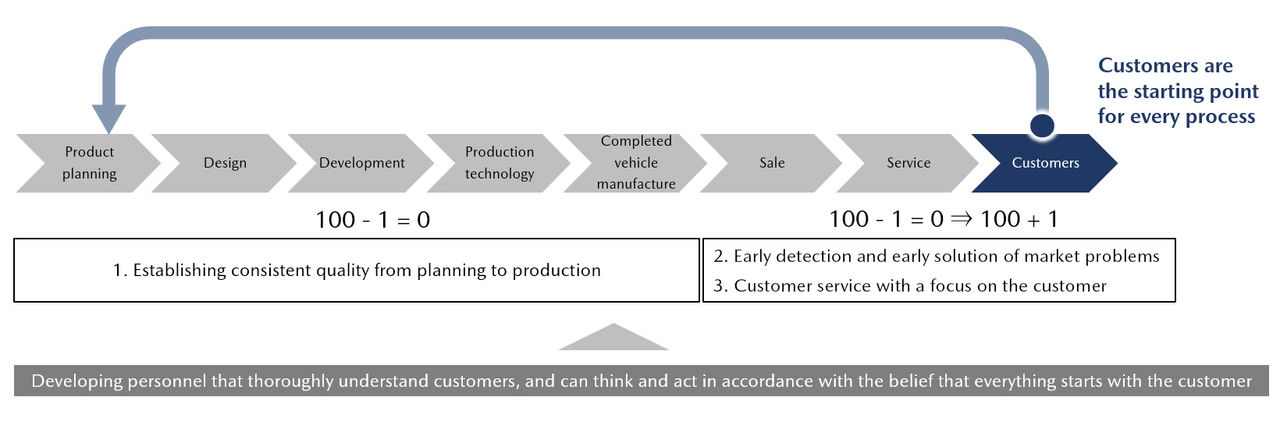

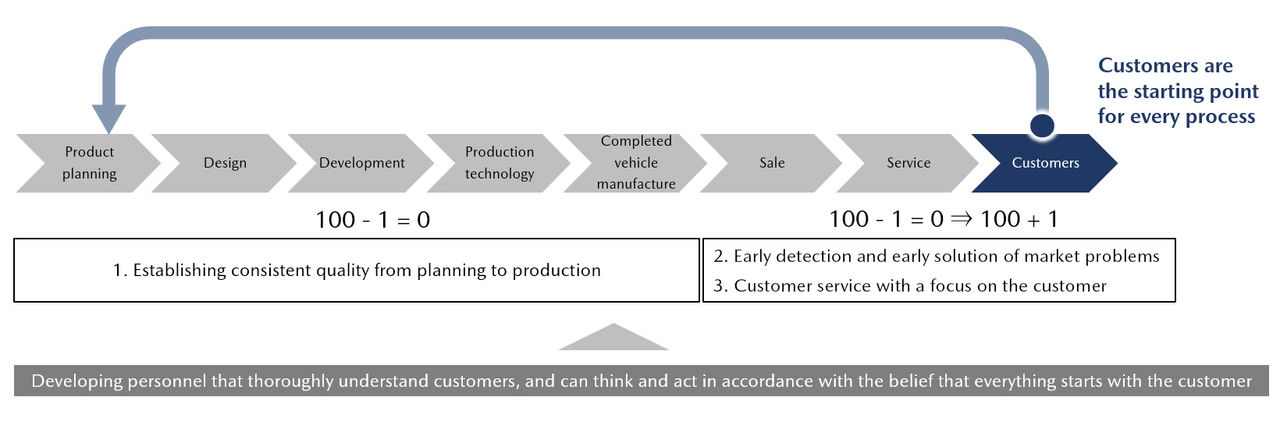

To ensure that Mazda is always able to ensure customer safety, trust, and excitement through its product and services, the Company positions customers as the starting point of all its business activities and makes ongoing efforts to improve quality. Mazda recognizes that thorough quality assurance must account for both the outward appearance of products and also the processes used by customers. Accordingly, the Company works diligently to develop personnel who thoroughly understand its customers and who can think and act in accordance with the belief that everything starts with the customer.

Vehicle Production Based on the "100 − 1 = 0" Belief

1. Consistent Quality in Processes Spanning from Planning to Production

The "100 − 1 = 0" belief expresses Mazda's belief that, even if it produces 100 vehicles, the customer that buys one of these vehicles will not see their car as one of this 100. For them, it is there only one, irreplaceable car. Accordingly, if that one car is defective, it has no value for the customer. In keeping with this belief, Mazda aspires to ensure that every customer is satisfied with the highest levels of quality, and therefore values each and every vehicle delivered to customers and aims to achieve zero defects. Adhering to the basic principles of manufacturing and based on a full understanding of its mechanisms, all related departments work in close collaboration to ensure consistent quality in all processes, spanning from planning to production.

Process Initiatives for Changing "100 − 1 = 0" to "100 + 1"

2. Early Detection and Resolution of Market Problems

If an unpredictable problem arises in the market, it may result in loss of trust from customers ("100 − 1 = 0"). To avoid this situation, Mazda promotes quality assurance activities for the early detection and resolution of any trouble pointed out by customers.

3. Customer Service with a Focus on the Customer

Through coordination among sales locations and consistently earnest engagement with customers as well as close communication, Mazda aims to establish an emotional connection with customers based on enduring trust ("100 − 1 = 0" → "100 + 1").

Initiatives

Mazda Quality Management System

To make faithful and unceasing efforts and constantly ensure quality that can always satisfy the expectations and live up to the trust of customers, Mazda has established the Mazda Quality Management System based on ISO 9001* and has applied this system to the series of processes spanning from product development to production, sales, and after-sales services. At overseas production sites, the Company is establishing frameworks that encourage local employees to take autonomous action to improve quality. We are also promoting the acquisition of ISO 9001 at sites around the world. The Company thereby aims to drive improvements in the quality of Mazda vehicles, which are produced and sold worldwide. Under our quality governance systems, global quality managers are responsible for practicing regular communication with representatives from each region who are most closely connected to local markets in order to gather input from the front lines on whether the Company is living up to the expectations and trust of customers and gain information on the issues they face. This communication helps facilitate the early detection and resolution of issues. Furthermore, quality representatives for each region participate in regular meetings where they share best practices with the goal of enhancing Mazda's global quality assurance processes.

* ISO 9001 is a set of international standards for quality management and assurance.

Acquisition of ISO 9000 Series

| Year of Acquisition | Types of ISO Certification | Certified Organization, Product, Service, Etc. |

|---|---|---|

| 1994 | ISO 9002 | Mazda Motor Corporation (first instance of certification by a Japanese automobile manufacturer): Vehicles produced at Hiroshima Plant and Hofu Plant |

| 1996 | ISO 9001 | Mazda Motor Corporation: Engineering, product development, manufacturing, and customer service |

| 2001 | ISO 9001 | Mazda Motor Corporation: Accessories, knock-down production, product planning, design Mazda Engineering & Technology Co., Ltd.: Specially equipped vehicles (TESMA), etc. (application scope expanded) Auto Alliance (Thailand) Co., Ltd. |

| 2007 | TS 16949 (ISO 9001 Sector certificate) |

Changan Ford Mazda Automobile Co., Ltd. (currently Changan Mazda Automobile Co., Ltd.) Changan Ford Mazda Engine Co., Ltd. (currently Changan Mazda Engine Co., Ltd.) |

| 2015 | ISO 9001 | Mazda de Mexico Vehicle Operation Mazda Powertrain Manufacturing (Thailand) Co., Ltd.2018 |

| 2018 | ISO 9001: 2015 | Mazda Motor Corporation: Head Office, Hiroshima Plant and Hofu Plant, Mazda de Mexico Vehicle Operation, and Auto Alliance (Thailand) Co., Ltd. |

| IATF 16949:2016 (ISO 9001 Sector certificate) |

Changan Mazda Automobile Co., Ltd. Changan Ford Mazda Engine Co., Ltd. (currently Changan Mazda Engine Co., Ltd.) |

Customer-Oriented Quality Improvement

Development of Understanding of Our Customers

Activities to Turn Customer Feedback into Knowledge

Recognizing that customer feedback from across the globe is our most valuable asset for automobile development, Mazda is compiling a database of such feedback so that this information can be incorporated into product planning and development.

Sharing of Past Cases

Mazda shares the lessons learned from past cases through exhibits of actual defective products and e-learning programs in order to drive reforms in behavior.

【Statistics from FY March 2025】

- Participation in exhibits and e-learning programs by approx. 14,000 individuals

Exhibit

Participant in e-learning program

Focus on Thinking from the Customer's Perspective

Quality Awareness-Raising Activities

Mazda holds quality meetings on a regular basis. At these meetings, officers from various fields take turns communicating their commitment to compliance and quality in their own words to all employees. This provides opportunities for individual employees to reflect on and think about their work, thereby enhancing their compliance and quality awareness.

Quality Education

Quality control education programs are provided for employees for the purpose of developing human resources capable of proactively identifying and resolving problems from the customer's viewpoint and working for continuous improvement. Quality education courses taught by internal instructors are offered, and employees take appropriate courses based on their job roles or rank.

Major Quality Education Courses (FY March 2025)

| Program | Objective | |

|---|---|---|

| 1 | Quality education program for new employees | Fostering of understanding of basic quality control concepts (customer-oriented attitude, continuous improvement efforts) |

| 2 | Quality education by rank | Development of understanding of quality management approaches tailored to different ranks or job roles |

| 3 | Quality management method training | Cultivation of skills for applying and practically implementing specialized quality management techniques |

Action Based on the Customer

Quality Control Circle Activities

Mazda promotes quality control (QC) circle activities to encourage employees to identify and resolve problems by themselves. These activities have been implemented for over 60 years as a core element of our corporate activities. The All-Mazda QC Circle Competition held every year at the Head Office in Hiroshima has become an entrenched part of our global activities, seeing participation from quality circles of Japanese dealerships as well as those of overseas production sites.

Commitment to Consistent Quality in Processes Spanning from Planning to Production

Process Assurance

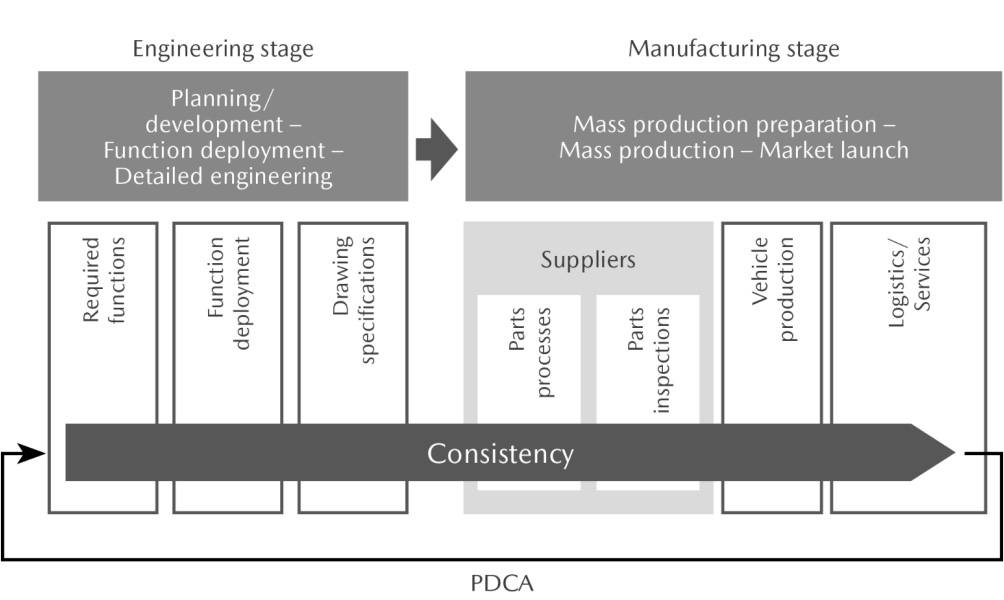

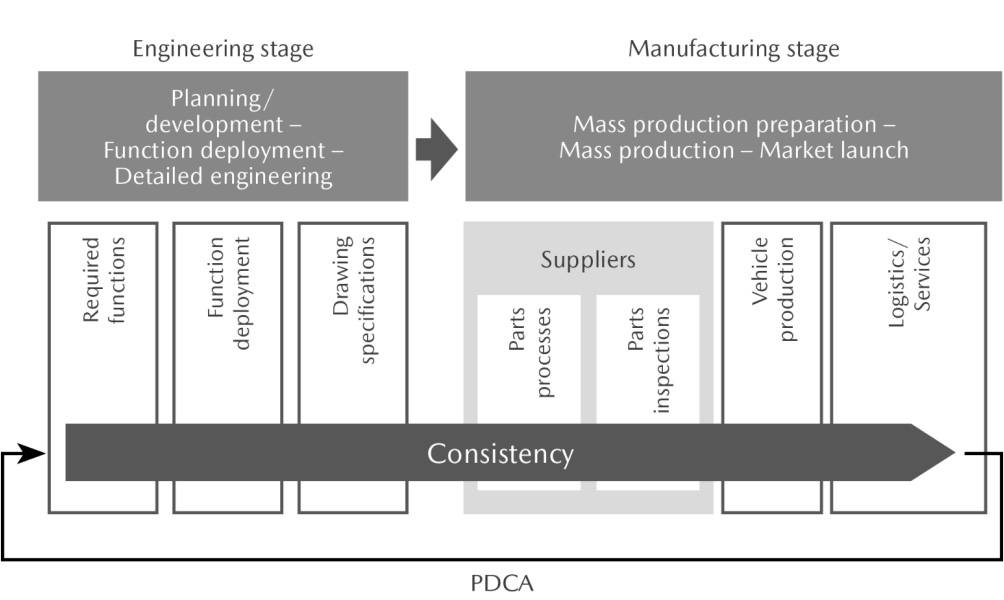

In its quality assurance efforts, Mazda is committed to process assurance to improve the performance of products as well as to enhance the quality of new technologies in response to environmental safety regulations and electrification trends. Process assurance is an approach for ensuring a consistent quality level in all processes spanning from engineering (planning and product development) to product creation (purchasing, vehicle production, logistics, and customer services). Through this approach, the Company identifies the important elements necessary to guarantee the quality of functions and performance based on an accurate understanding of customer needs and expectations. The Company has also established frameworks for maintaining and managing these elements in every process spanning from engineering to manufacturing. The cooperation of partners is imperative in improving quality levels. For this reason, the Company promotes personnel and technology exchanges as well as other co-creation activities. Furthermore, the Company identifies the functions and performance that embody the joy of driving for each stage from before getting in the car to after starting driving so as to achieve increased consistency in quality.

Early Detection and Resolution of Market Problems

Swift and Comprehensive Quality Improvement

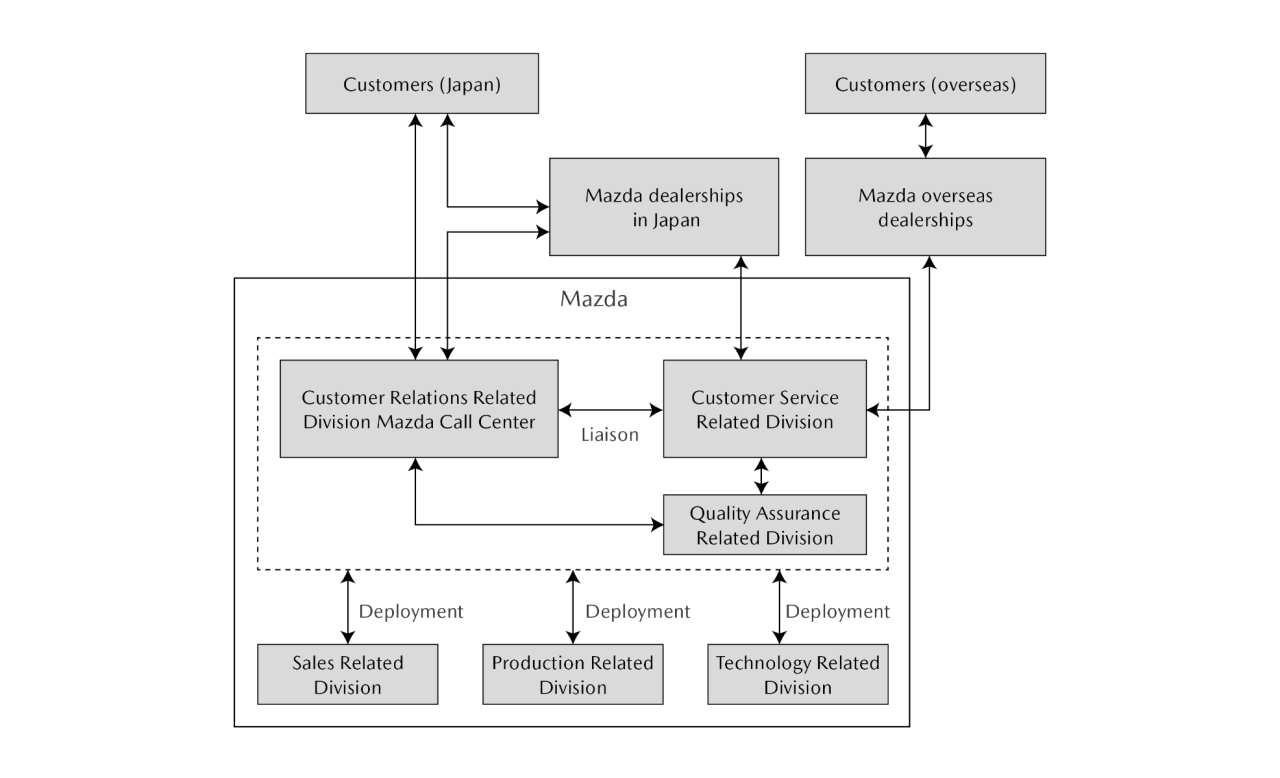

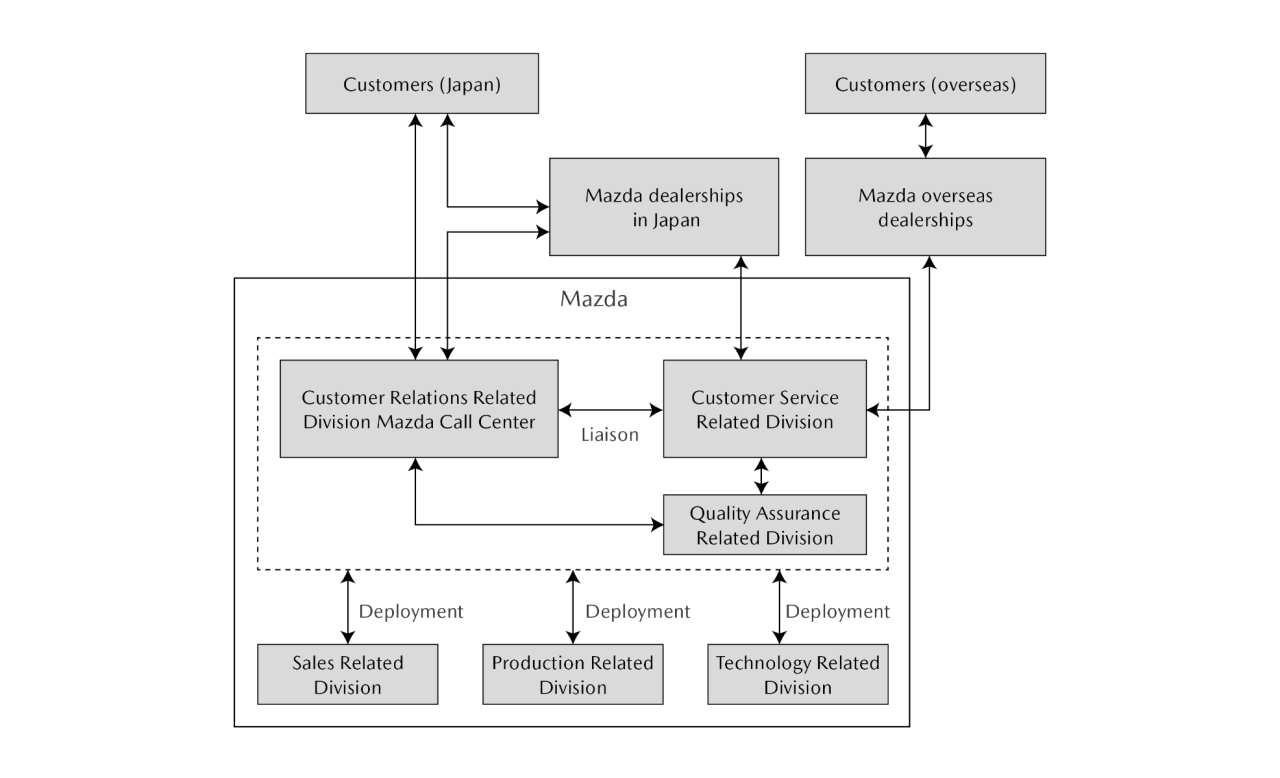

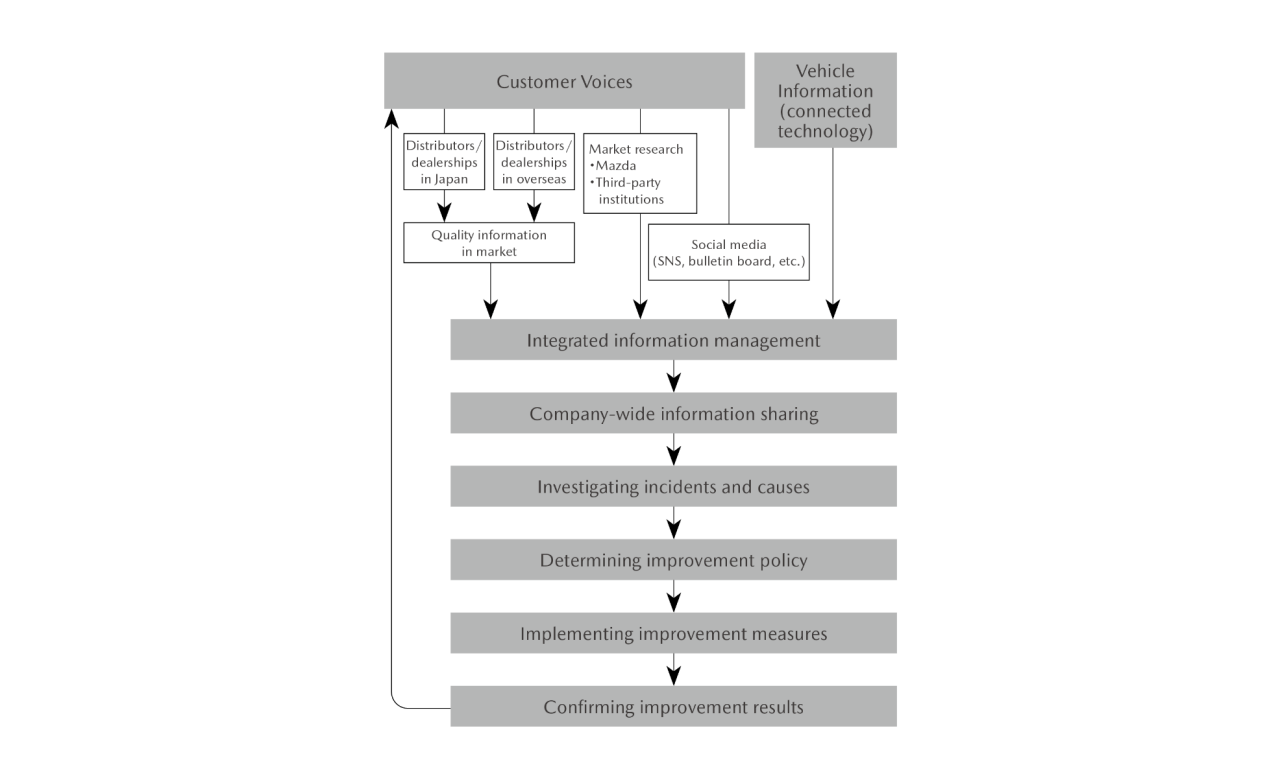

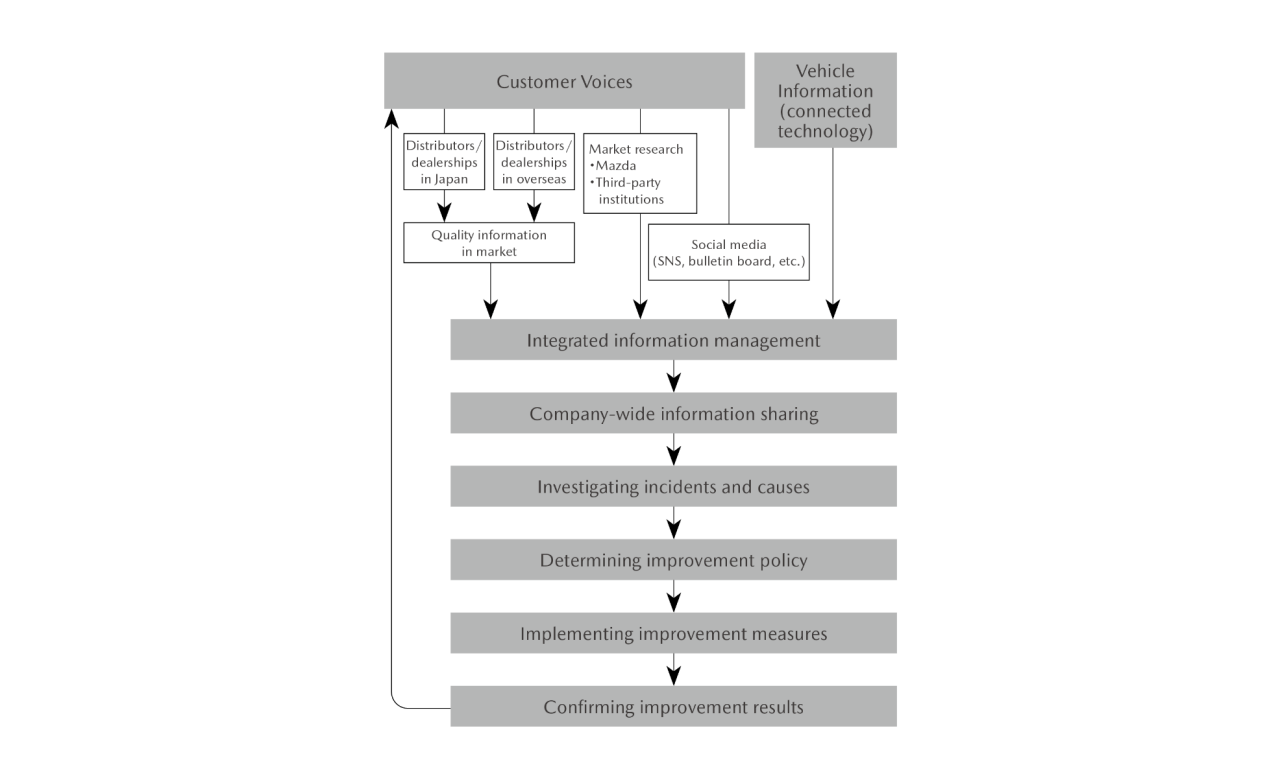

To facilitate early detection and resolution of market problems, Mazda has established a system for integrated management of all quality information. Such information is gathered from distributors and dealerships in Japan and overseas and by employing the results of surveys by external institutions, conducting the Company's own market research, and utilizing connectivity technologies to collect vehicle information. Through this system, the collected information is shared throughout the Company in real time. By using the system and closely monitoring daily progress, the Company investigates quality-related incidents and their causes, determines and implements improvement measures, and confirms the results. In this manner, the Company works to achieve swift and comprehensive improvement.

Quality Improvement System

【Examples of Surveys, Analyses, and Improvement Measures】

- Collection of customer feedback through proprietary Mazda market surveys

- Market surveys conducted by third parties

- Analysis of customer feedback via social media

- Analysis of vehicle information obtained through connectivity technologies

Quality Assurance Systems Placing Customer Safety and Security as Highest Priority

Mazda conducts inspections on conformity with the laws and regulations of relevant countries and on functions to be used by customers. Meanwhile, development, production, and quality divisions audit each other from their respective independent standpoints. These provisions make for quality assurance systems that place customer safety and security as the highest priority.

Overview of Recall Procedures*

- Registration with authorities in each jurisdiction in accordance with the laws and regulations of each country and region

- Disclosure to customers via direct mail, telephone, and other methods and explanations at dealerships

- Disclosure of information on recalls on Mazda's corporate website

* Recall procedures may vary by country or region.

Customer Service with a Focus on the Customer

Mazda aims to provide customer service that customers can always rely on. To this end, in addition to supplying safe, reliable, and comfortable vehicles, Mazda also strives to offer an ownership experience that allows customers to enjoy all areas of vehicle ownership, including visits to dealerships, with no stress. The foundation for these efforts is furnished through the development and provision of tools and service manuals and the construction of parts supply networks. Furthermore, the Company is working with dealerships in Japan and overseas to reform operations, create new touch points with customers, and cultivate human resources capable of considering and acting toward customers' happiness.

| Tools and service manuals |

|

| Development of dealership sales staff |

|

Initiatives at Dealerships and Distributors

Mazda is committed to providing dealership and distributor experiences that accommodate the needs of individual customers. The Company therefore promotes operational improvement measures driven by dealerships and distributors with the aim of heightening process quality and creating more comfortable work environments for employees. The Mazda Production System, which is built on Mazda's accumulated production insight, is a central component of these initiatives. Through initiatives involving all dealership and distributor employees, the Company seeks to eliminate operational inefficiencies while increasing the value of processes from the perspective of the customer. In FY March 2024, the Company expanded the scope of dealerships and distributors in which improvements are pursued to include those located overseas in addition to those in Japan. To enhance the level of customer satisfaction initiatives at Mazda dealerships and distributors, the Company has prepared award systems for sharing and honoring best practices demonstrated by the staff of dealerships and distributors that have contributed to increased customer satisfaction through excellent teamwork and the sales and service staff members who achieved outstanding results.

Staff Awards and Shop Awards

| Program | Frequency | Objective |

|---|---|---|

| Staff awards and shop awards | Once a year | Recognition of dealerships that have achieved their targets as a result of all staff members' customer-oriented activities and excellent teamwork; sharing of best practices from shops producing outstanding results at presentation meetings hosted by Mazda Dealerships Association across Japan |

Responses to Expectations and Opinions of Customers

At Mazda dealerships and distributors around the world, systems have been established to gather opinions and requests from customers, to respond to them honestly, accurately, and quickly, and to reflect this input in sales and services in cooperation with the Mazda Head Office.*1 The contacts for each market area as well as an FAQ section*2 are available on Mazda's corporate website for the convenience of customers. To strengthen bonds with customers, Mazda conducts global customer satisfaction surveys focusing on the Mazda brand experience, sales and after-sales services, ownership cost, product attractiveness, and other specific items. Through these surveys, the Company identifies problems in each market and addresses them in cooperation with local dealerships and distributors as part of a plan–do–check–act (PDCA) cycle.

*1 Distributor list by country/region

*2 Inquiries from Japan/FAQ (in Japanese only)

Customer Service Framework