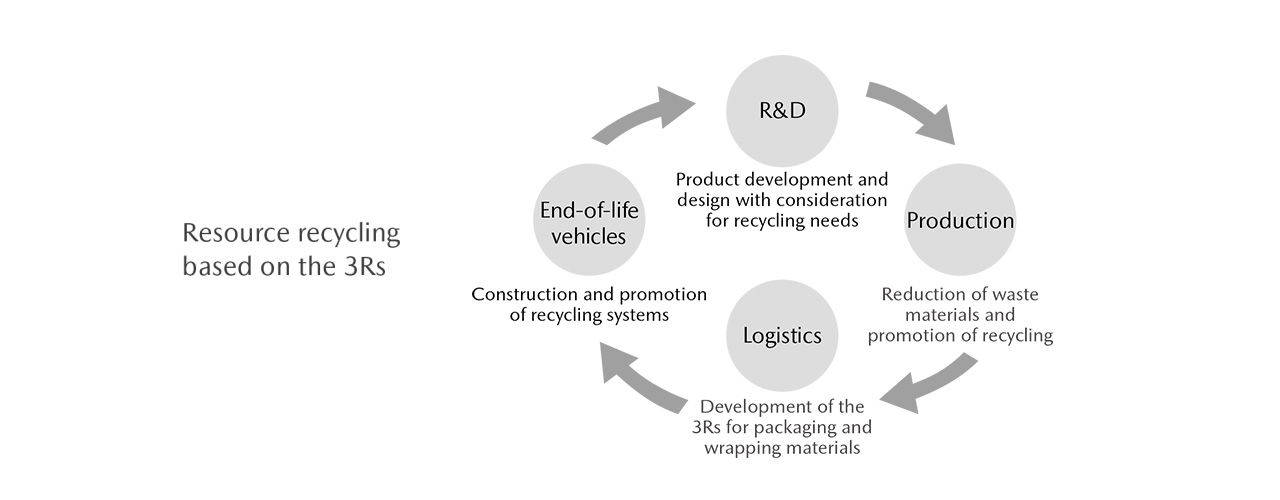

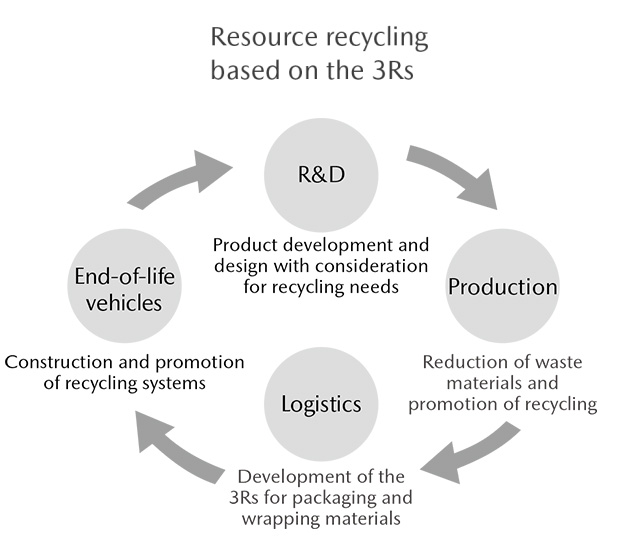

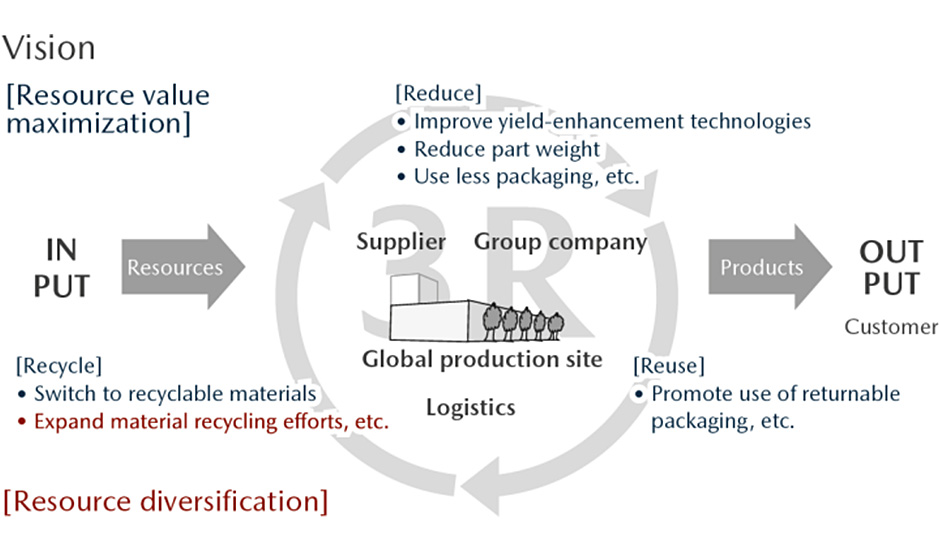

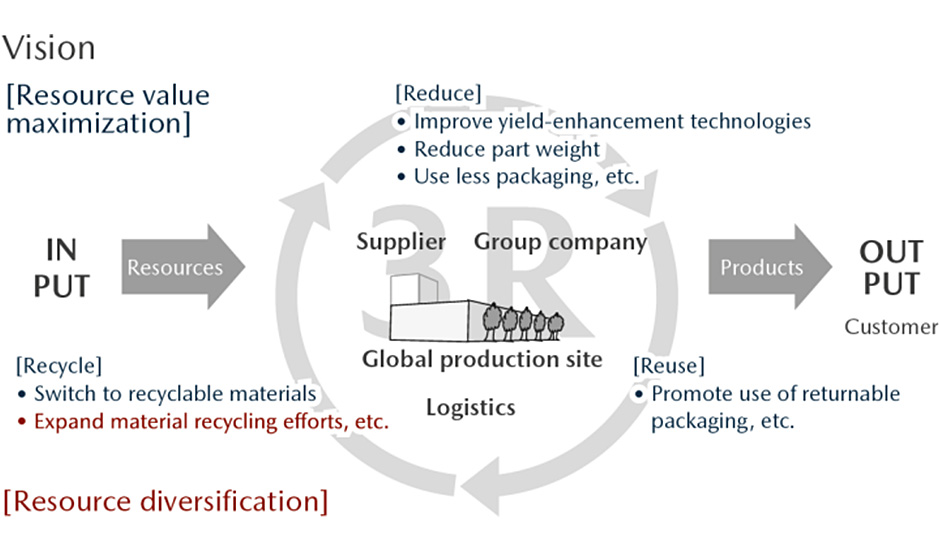

Mazda aspires to be a company that coexists in harmony with the planet and is committed to comprehensive resource recycling and waste reduction measures. Development-related resource recycling measures include promotion of the 3Rs (reduce, reuse, and recycle) and circular economies for a perspective encompassing the entirety of automobile life cycles. Meanwhile, the Company will advance initiatives in production, logistics, and other areas to contribute to the realization of a recycling-oriented society from a "well-to-wheel" perspective and a global and supply chain perspective, taking into account the entirety of the automobile supply chain.

RESOURCE CIRCULATION

Materials

Basic Approach (Materials)

Initiatives (Materials)

Product and Technology Development

Efforts to Increase Recyclability of New Vehicles

Many limited resources, such as steel, aluminum, plastics, and rare metals, are used in the production of vehicles. Mazda is incorporating 3Rs design principles into all vehicles currently under development to increase the recyclability of new models.

Specific Initiatives

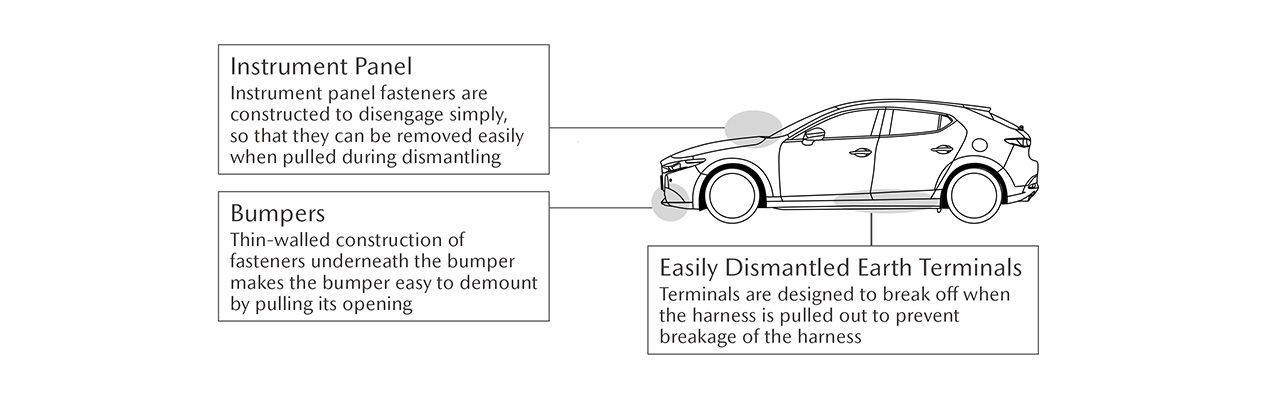

- Research into vehicle design and dismantling technologies that simplify dismantling and separation to make recyclable parts and materials easier to remove

- Use of easily recyclable plastics, which constitute the majority of automobile shredder residue (ASR)* by weight

* ASR refers to the residue remaining after the crushing or shredding of what is left of the vehicle body (following the removal of batteries, tires, fluids, and other parts requiring appropriate processing as well as the removal of engines, bumpers, and other valuable parts) and separating and recovering metals.

Design Provisions for Simplified Dismantling and Separation of Vehicle Parts

Expanded Adoption of Biomaterials

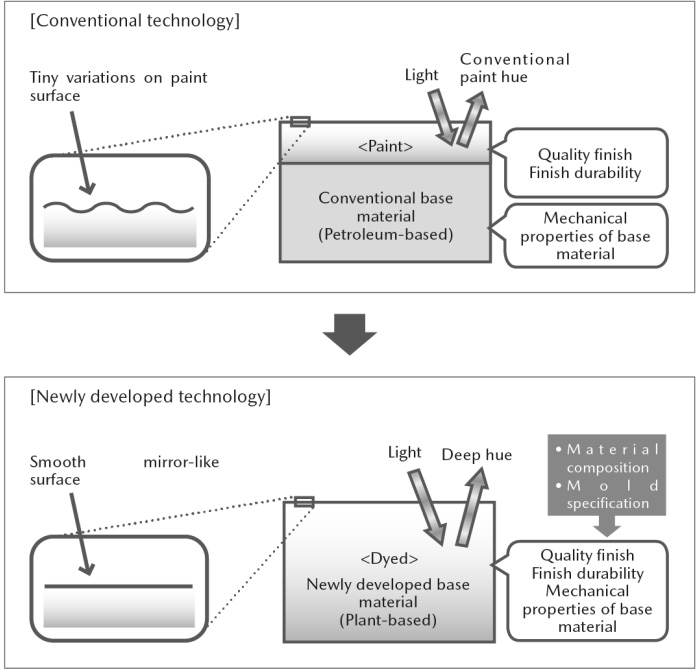

Mazda has been developing plant-derived biomaterials that have the potential to help reduce environmental impacts by curbing the use of fossil fuels and lowering CO₂ emissions. In 2006, the Company became the first in the automotive sector to develop high heat-resistant, high-strength bioplastic for vehicle interior parts. In 2007, Mazda succeeded in the development of the world's first*1 biofabric for vehicle seat covers made with completely plant-derived fibers. In 2014, a bio-based engineering plastic*2 suitable for use in vehicle exterior parts was developed by the Company. Mazda is currently expanding its adoption of these materials.

*1 Source: Mazda Motor Corporation (September 2007)

*2 The bio-based engineering plastic was developed by Mazda Motor Corporation in collaboration with Mitsubishi Chemical Corporation.

Bio-Based Engineering Plastic Development Initiatives

| 2014 | Mazda developed a bio-based engineering plastic featuring a high-quality finish without painting. By developing paint-less technologies for interior and exterior parts that take advantage of the characteristics of this material, the Company not only endowed this material with excellent environmental performance but also created a high-quality finish that could not be achieved with conventional paint, thereby contributing to environmental protection while reducing production costs by eliminating the painting process. |

|---|---|

| 2017 | Mazda developed materials suitable for making large, intricately shaped exterior parts, such as front grilles, and optimized the die specifications in order to substantially enhance the formability of these parts. |

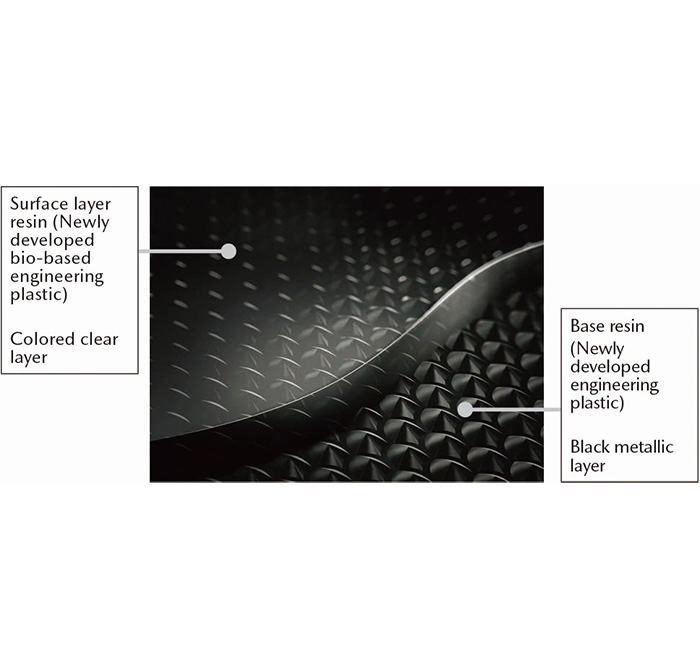

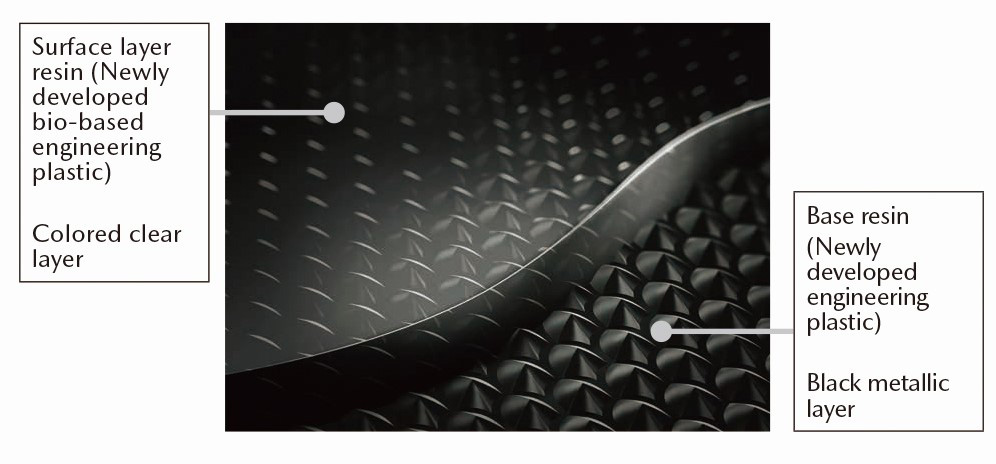

| 2018 | Mazda developed a new technology for two-layer molding of pattern-designed bio-based engineering plastic that enabled the molding of a transparent surface layer and a base layer with a pattern-engraved surface, both of which are made of eco-friendly bio-based engineering plastic. The new technology reduced environmental impacts while making it possible to provide elaborate shaded patterns of deep color that were not possible with prior technologies. |

| 2020 | Mazda received the Award for Science and Technology (Development Category) of the 2020 Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology for the development of the aforementioned bio-based engineering plastic. |

| 2021 | Mazda received the Aoki Katashi Innovation Award from the Japan Society of Polymer Processing for the development of the aforementioned technology for two-layer molding of pattern-designed bio-based engineering plastic. |

| 2023 | Mazda received a METI Minister's Prize at the Ninth Monodzukuri Nippon Grand Awards for the development of the aforementioned technology for two-layer molding of pattern-designed bio-based engineering plastic. |

Paint-less technology for interior and exterior parts (developed in 2014)

Technology for two-layer molding of pattern-designed bio-based engineering plastic (developed in 2018)

Production and Logistics

Plant 3Rs and Global Zero-Emissions and Resource Recycling Initiatives

The Mazda Group continues to expand its global efforts to achieve zero emissions and recycle resources through measures such as efficiently using resources to prevent waste and promoting the 3Rs for resources.

| 2030 Goals | 2050 Goals |

|---|---|

Achieve zero emissions in manufacturing and logistics processes on a global basis

|

Zero emissions through expanded resource recycling initiatives in manufacturing and logistics processes on a global basis

|

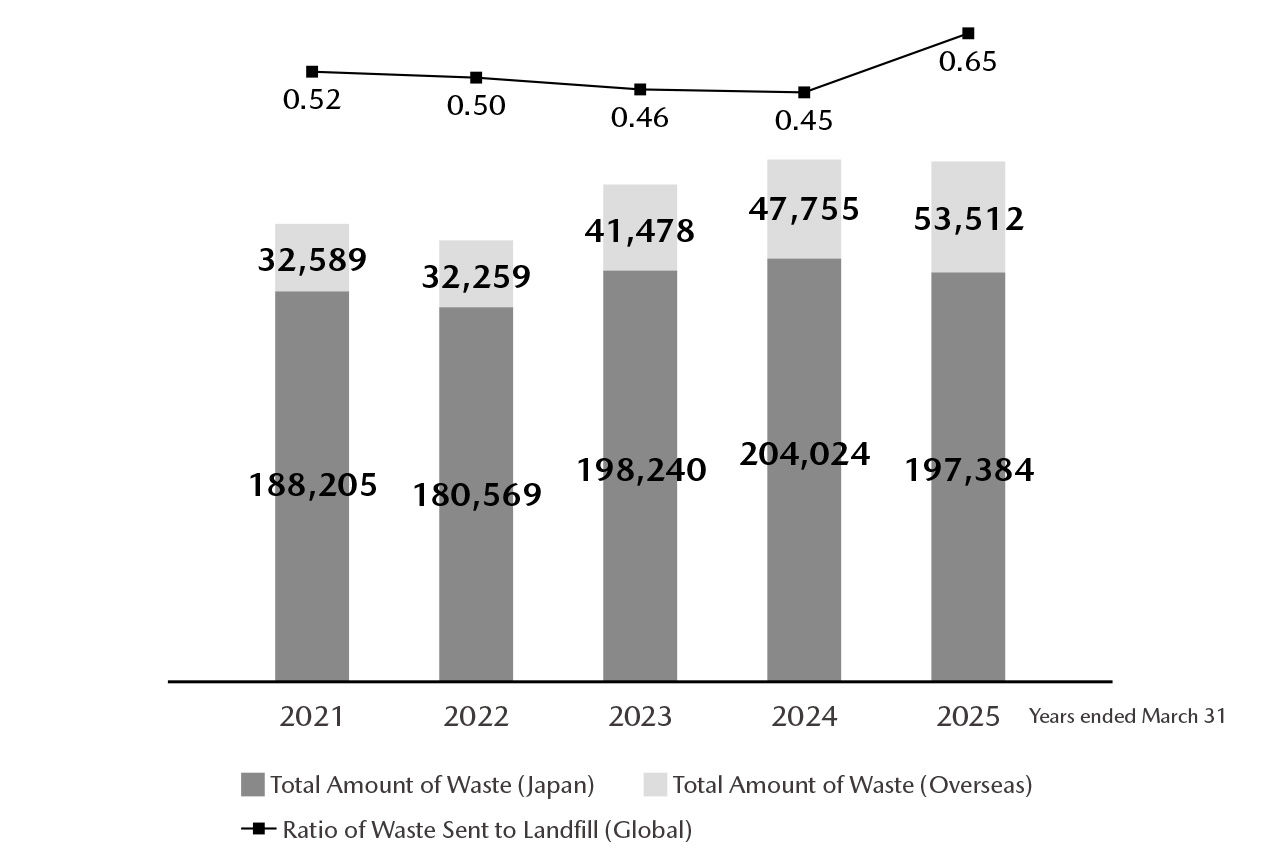

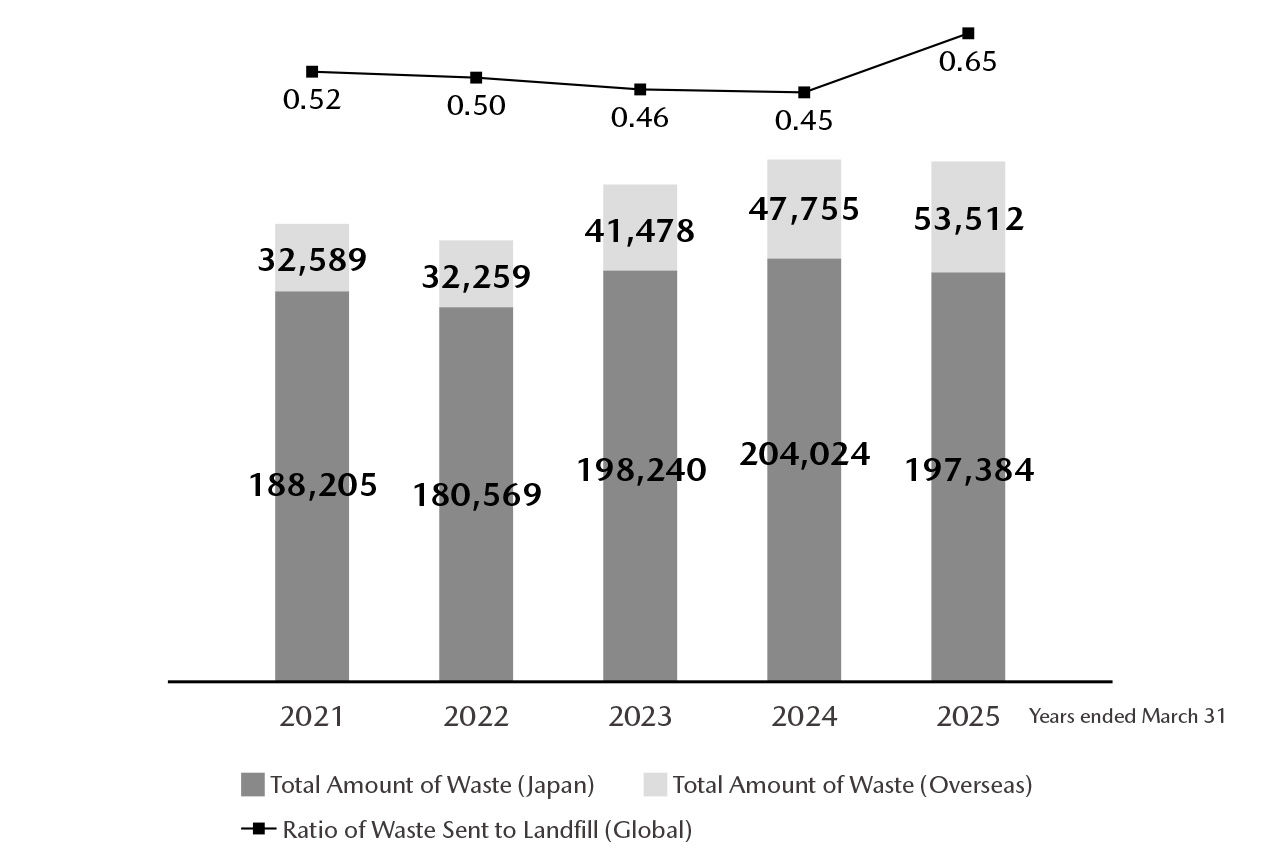

Total Amount of Waste/Ratio of Waste Sent to Landfill (t/%)

Production Materials: Maintenance of Zero Landfill Waste Status and Reduction of Waste

To reduce landfill waste at its four principal domestic sites* to zero, Mazda is promoting reductions in the volume of manufacturing by-products and waste, more rigorous sorting of waste, and increased recycling. The Company was thereby able to achieve zero landfill waste, and it has maintained this status from FY March 2009 to FY March 2025. As part of its waste reduction efforts, the Company has been recycling materials to ensure that plastic packaging materials used in the vehicle and transmission assembly processes can be reused as raw materials through stricter sorting of packaging by material and quality. Furthermore, Mazda has been proactively utilizing plastic pallets made from recycled materials to transport parts overseas.

【Statistics from FY March 2025】

- Reduction in total amount of waste generated of 85% in comparison to FY March 1991

* Headquarters (Hiroshima); Miyoshi Plant; Hofu Plant, Nishinoura District; and Hofu Plant, Nakanoseki District (including product development and other non-manufacturing areas)

Logistic Materials: Reduction of Packaging and Wrapping Materials

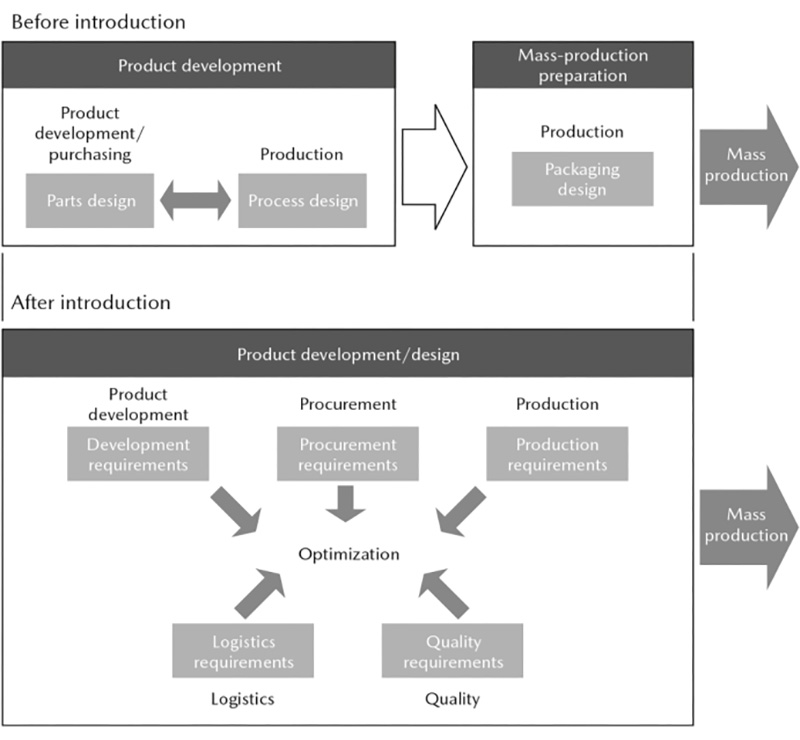

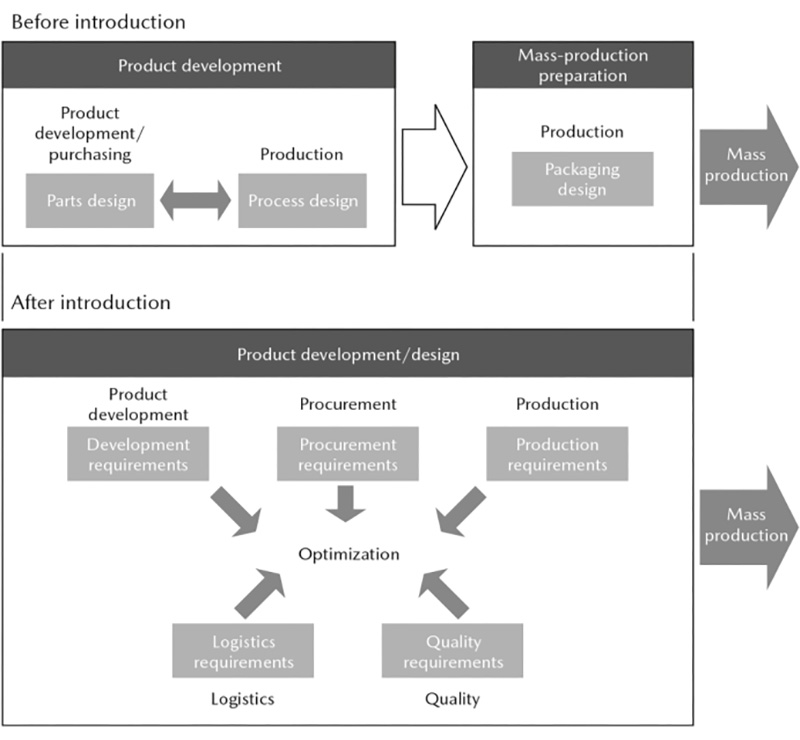

Mazda is moving forward with 3Rs initiatives including using returnable containers, simplifying packaging specifications, and recycling materials. In regard to the transportation of repair parts in Japan and overseas and the export of parts to overseas plants, ongoing coordination is being promoted between departments in five areas—development, production, procurement (purchasing), logistics, and quality—to optimize parts procurement and vehicle manufacturing from the stage of product development and to facilitate strong cooperation across the supply chain. These efforts are anticipated to result in reduced volumes of packaging and wrapping materials and an increased packaging filling rate.

【Statistics from FY March 2025】

- Reduction in volumes of packaging and wrapping materials used of 19.7% in comparison to FY March 2020

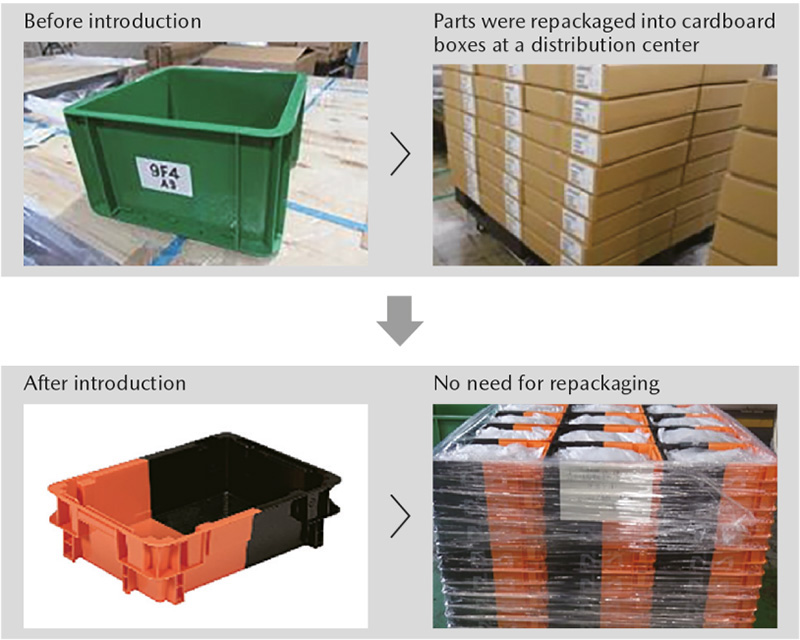

In the past, Mazda has adopted an approach toward transporting parts to overseas plants and repair parts to overseas bases that involved repacking parts delivered from suppliers in cardboard boxes at distribution bases. However, the Company has since begun utilizing returnable containers that can be reused in order to reduce the use of packaging and wrapping materials. This new approach has contributed to reductions in the amount of packaging and wrapping materials used by eliminating the need for repacking in cardboard boxes at distribution bases and of later disposal of those boxes.

Mazda is also expanding its use of returnable new standard containers for parts to be transported to overseas plants. These containers make it possible for parts to be delivered to overseas plants in the state they were packed at suppliers with no need for repacking at distribution bases. Moreover, the new standard containers come in standardized sizes, contributing to more efficient use of container space and subsequently increased container filling rates. As of March 31, 2024, Mazda had completed introduction of new standard containers for transportation to plants in the United States, China, Mexico, and Thailand. Furthermore, we began asking suppliers in Mexico to use these containers when delivering certain parts in FY March 2025. These efforts have resulted in the container filling rate rising from 70% to 90%, leading to reductions in packaging and wrapping materials, the number of containers needed, and the number of transportation truck services used. These gains have also contributed to lower CO₂ emissions. Going forward, Mazda will continue to expand the use of new standard containers to further reduce packaging and wrapping material use and environmental impacts.

Coordinated material reduction initiatives

Introduction of returnable containers

Collection and Recycling of Vehicles and Parts

Almost all materials used in vehicles can be recycled. Implementing thorough recycling and waste reduction initiatives to ensure that limited resources are used effectively, Mazda promotes efforts to contribute to the realization of a recycling-oriented society.

Measures in Response to Japan's Act on Recycling of End-of-Life Automobiles

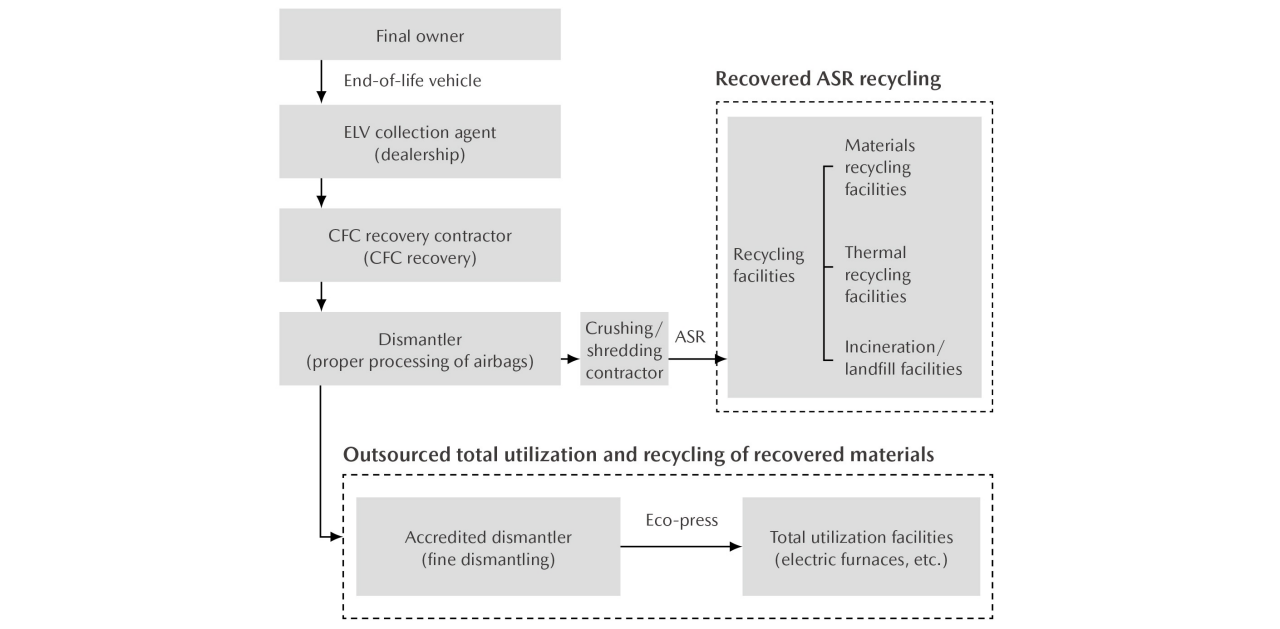

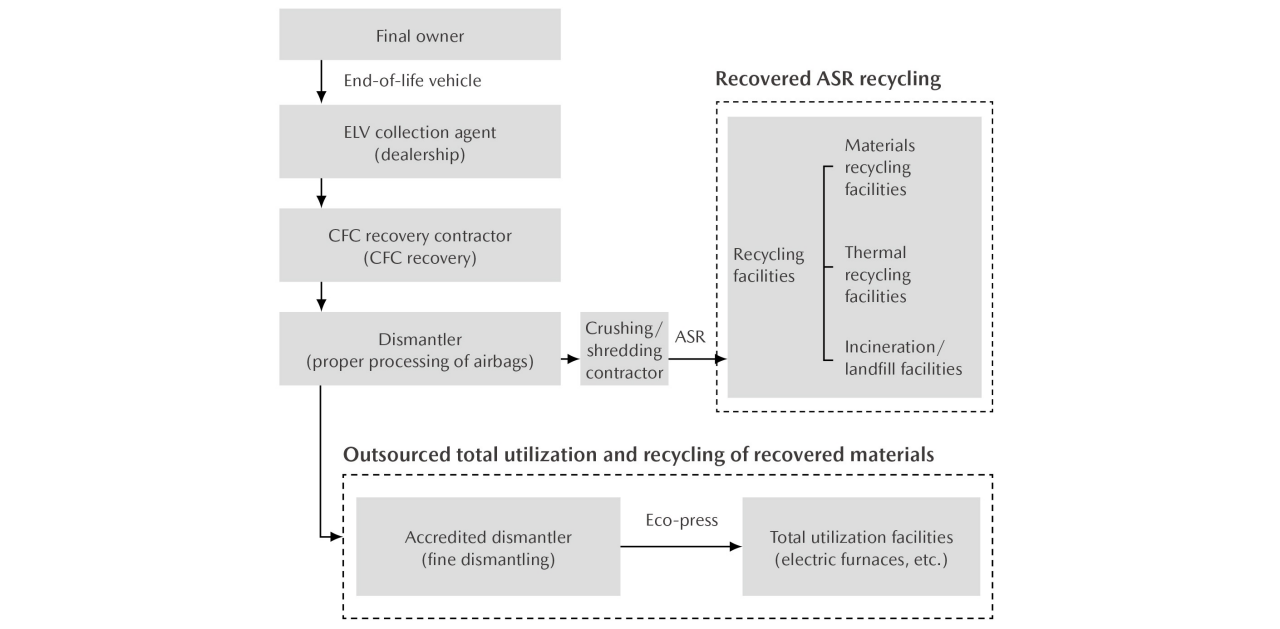

Mazda properly processes three designated items in accordance with the Act on Recycling of End-of-Life Automobiles (chlorofluorocarbons, airbags, and ASR). In addition, the Company is actively working to recycle these items through unique technologies and measures. In regard to ASR, Mazda is working through the Automobile shredder residue Recycling promotion Team (ART), a consortium of 12 companies including Nissan Motor Co., Ltd., Mitsubishi Motors Corporation, and Mazda, to comply with the law and achieve progress in the reuse of resources. The Company also promotes recycling at dealerships. Dealerships collect vehicle recycling fees at the time of sale of new vehicles and collect end-of-life automobiles from their final owners in order to transfer them to disposal processing companies.

The Act on Recycling of End-of-Life Automobiles was revised in February 2012 to include lithium-ion batteries (LiBs) and nickel-metal hydride (NiMH) batteries as items for advance collection before dismantling of end-of-life automobiles. Mazda is committed to collecting LiBs installed in its vehicles through the LiB Joint Collection System of Japan Auto Recycling Partnership, Ltd. The Company also collects NiMH batteries. Moreover, Mazda publishes disposal work procedure guidelines on its website and promotes appropriate disposal to ensure that the relevant business operators can safely recycle vehicles using LiBs and NiMH batteries as well as those equipped with deceleration energy regeneration system capacitors.

End-of-Life Automobile Recycling Process

【Resource Recycling Results in FY March 2025】

| Number of vehicles from which ASR was collected | 102,818 | |

|---|---|---|

| Number of vehicles from which airbags were collected | 100,787 | |

| Number of vehicles from which chlorofluorocarbons were collected | 98,881 | |

| Recycling ratios | ASR | 96.7% |

| Airbags | 96.9% | |

| Total contracting deposits received | ¥1,267,142,261 | |

| Total expenses for recycling | ¥1,249,901,505 |

ASR and Japan's Act on Recycling of End-of-Life Automobiles

Disposed vehicles consist of about 80% useful metals and about 20% automotive ASR that includes resin. Useful metals are recycled in cooperation with dismantlers, crushing and shredding contractors, steel manufacturers, and metal recycling-related companies. ASR, which used to be disposed by landfill, is now subject to the Act on Recycling of End-of-Life Automobiles, which was enacted in January 2005. This law was instituted in response to the rise in the risk of illegal dumping of end-of-life automobiles on the back of a surge in disposal costs due to overstrained final landfill sites and low iron scrap prices. As a result of the enactment of this law, car manufacturers are now responsible for recycling chlorofluorocarbons, which lead to global warming and ozone depletion; airbags, which require specialist knowledge for disposal; and ASR, using recycling fees deposited by final owners of end-of-life automobiles.

Recycling of End-of-Life Automobiles Overseas

Mazda is committed to the recycling of end-of-life automobiles overseas in accordance with the laws in each country and region through efforts centered on local distributors. In countries and regions planning to implement recycling-related laws, Mazda is preparing to respond in cooperation with the distributors in these areas. For vehicles equipped with LiBs and capacitors, the Company publishes disposal work procedure guidelines on its website and promotes appropriate disposal, as is also done in Japan, to ensure that the relevant business operators are able to safely dispose of these vehicles.

Europe

Based on European Union directives, European regional headquarters Mazda Motor Europe GmbH provides dismantling manuals to recycling contractors when introducing new models and has established a network to collect used vehicles from their final owners free of charge in cooperation with local distributors.

China

In accordance with Chinese regulations, Chinese production base Changan Mazda Automobile Co., Ltd. leads efforts to prepare dismantling manuals and manage substances with environmental impacts.

Collection and Recycling of Used Parts in Japan

Mazda collects damaged bumpers replaced through repairs so they can be recycled as plastic materials for use in plastic parts (new vehicle bumpers, undercovers, etc.).

【Statistics from FY March 2025】

- Collection of 41,389 damaged bumpers to be recycled

Water

Basic Approach (Water)

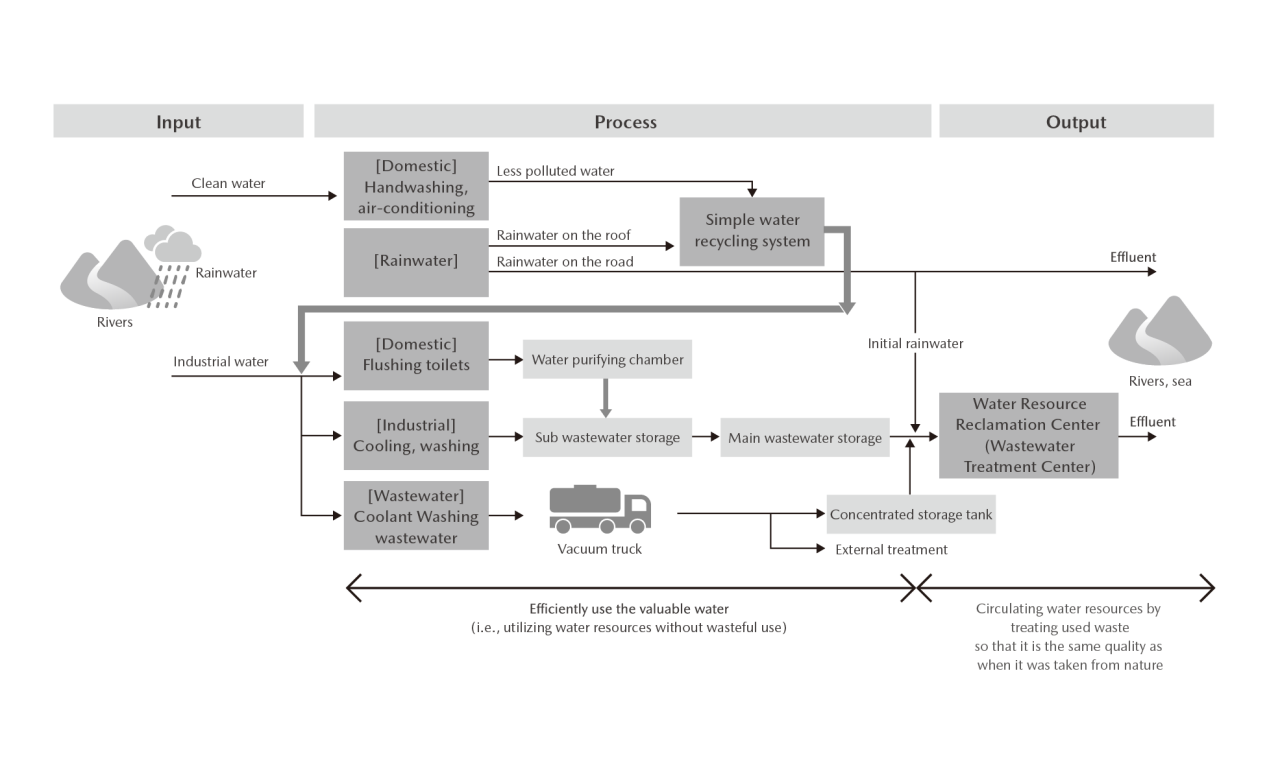

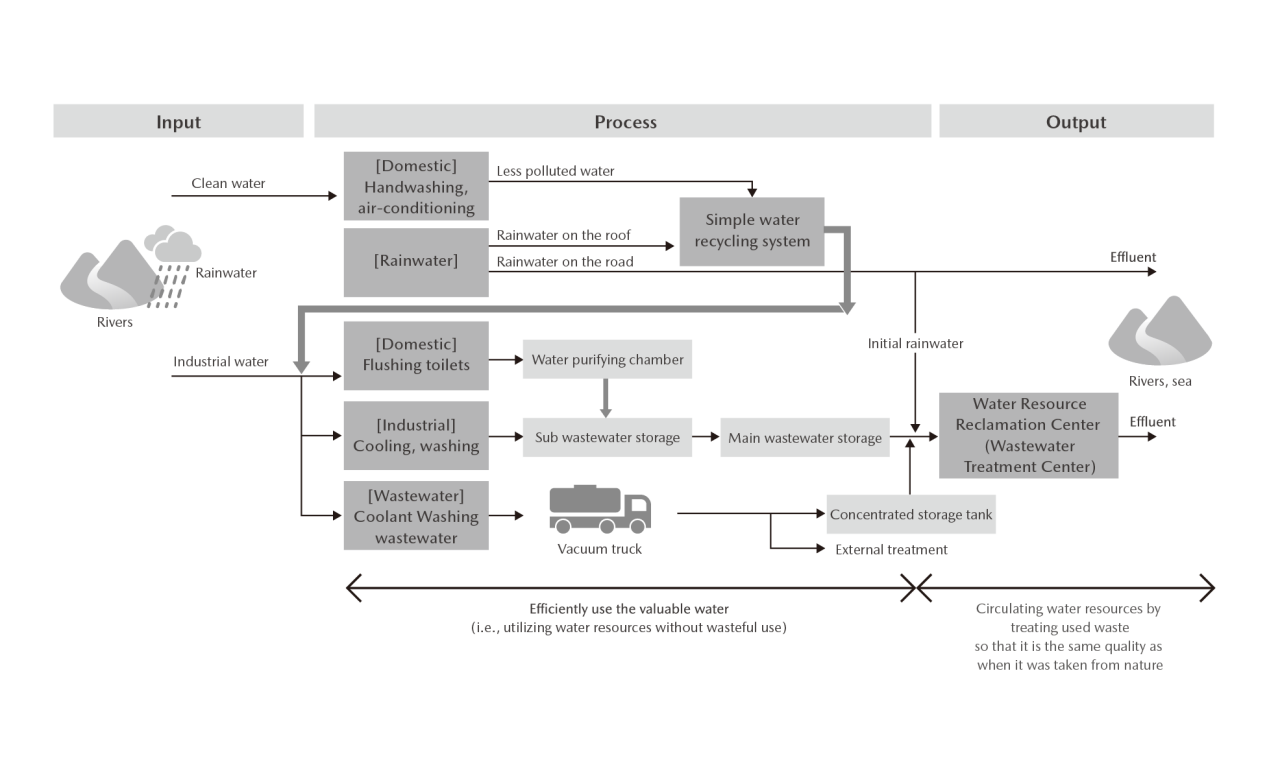

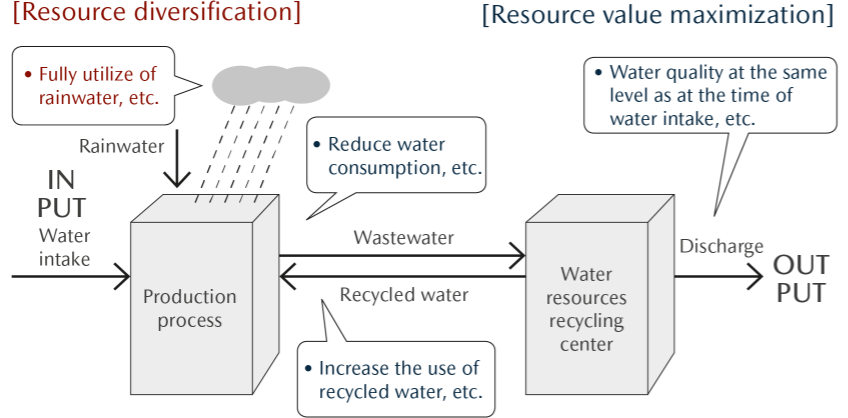

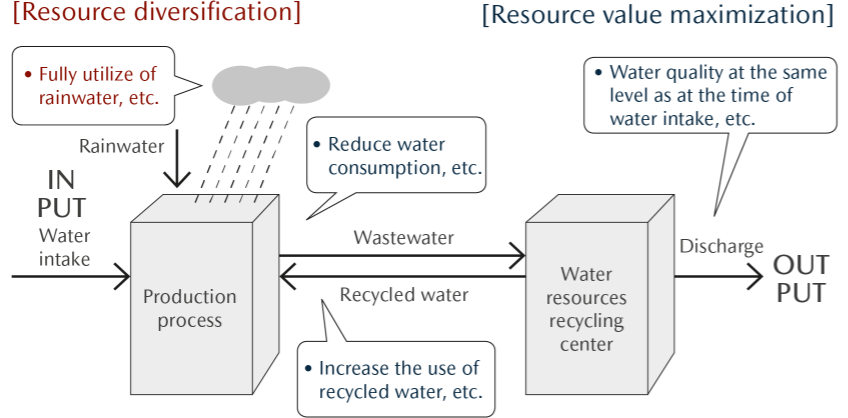

To conserve water resources, the Mazda Group promotes activities to eliminate wasteful water use and circulate water resources by treating used water so that it is the same quality as when it was drawn from nature.

| Shared Goals | |

|---|---|

|

|

| 2030 Goals | 2050 Goals |

| Implement an optimal approach to water resource recycling and circulation at a model plant* in Japan | Implement an optimal approach to water resource recycling and circulation in global manufacturing processes |

* A model plant is a pilot plant at which new innovations are tested in advance of introduction at other facilities.

Vision

Goals (Water)

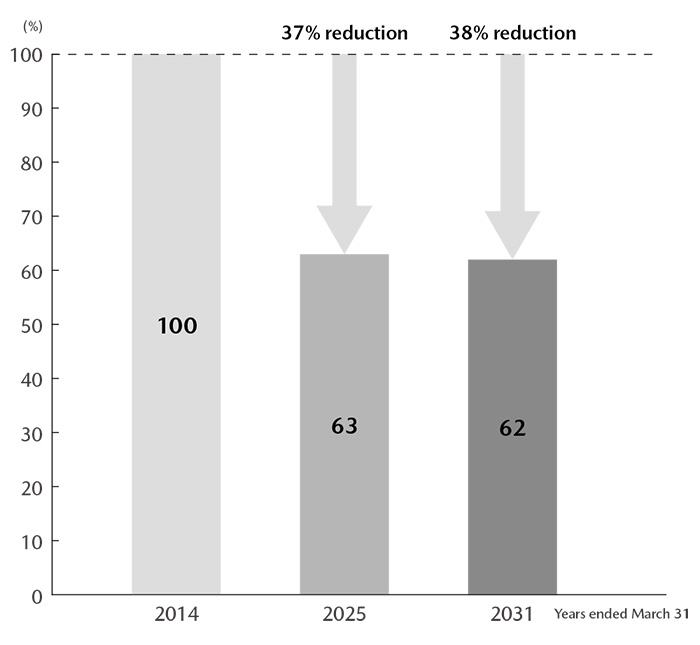

To guide its water resource reuse and recycling initiative at a domestic model plant, the Company has set a target of reducing water intake by all domestic Group companies by 38% by FY March 2031 compared with levels in FY March 2014. In order to achieve this target, the Company aims to reduce annual water use by 2% through measures including expanded use of rainwater and recycled water.

【Statistics from FY March 2025】

- Reduction of 37% in total domestic water intake in FY March 2025 (compared with FY March 2014)

Water intake by domestic Mazda Group companies

Initiatives (Water)

Water Resource Preservation

By clarifying inputs, processes, and outputs involving water resources in its business activities, Mazda is promoting initiatives to efficiently use these valuable resources (i.e., utilizing water resources without wasteful use). We thereby seek to minimize water usage and circulate water resources by treating used water so that it is the same quality as when it was drawn from nature.

To advance these initiatives, the Water Resource Group* was established consisting of members involved in water resource conservation. Six major themes have been defined for the activities of this group: (1) Elimination of wasteful use, (2) Reduction, (3) Reuse, (4) Recycling, (5) Utilization of rainwater, water sludge, and waste fluid, and (6) Building of communities and systems and development of human resources. Moreover, the group is divided into two teams that are tasked with analyzing current conditions, responding to issues, sharing information on initiatives with overseas plants, and supporting overseas plants' efforts to address relevant issues.

Water Resource Group

- Recycling and Circulation Team: Studies models in the field of wastewater treatment and reviews models and implements trials in the field of water intake

- Use Reduction Team: Introduces models and results of trials reviewed by the Recycling and Circulation Team at plants

* The Water Resource Group is a working group affiliated with the Business Site Environment Committee, an organization that examines and promotes environmental protection methods in manufacturing and logistics, as well as measures for reducing environmental impacts throughout the entire supply chain.

Specific Water Use Minimization Initiatives

Use Minimization and Reuse

- Prevention of overflows at cooling towers caused by excessive water supply and reuse of less-polluted water in circulation without draining in accordance with internal standards

- Installation of sensor on toilets that allow flushing only when the sensor detects the presence of the user to conserve water

- Reuse of water used in vehicle body cleaning processes at painting facilities through appropriate management based on water pollution standards; utilization of bacteria removal devices for water surpassing defined pollution thresholds so that it can be reused for other processes

Recycling of Wastewater and Utilization of Rainwater

- Recycling of less-polluted water, such as hand washing water and air conditioning drainage, through simple recycling systems so that it can be used together with stored rainwater for flushing toilets, watering green spaces, and other applications at Mazda sites