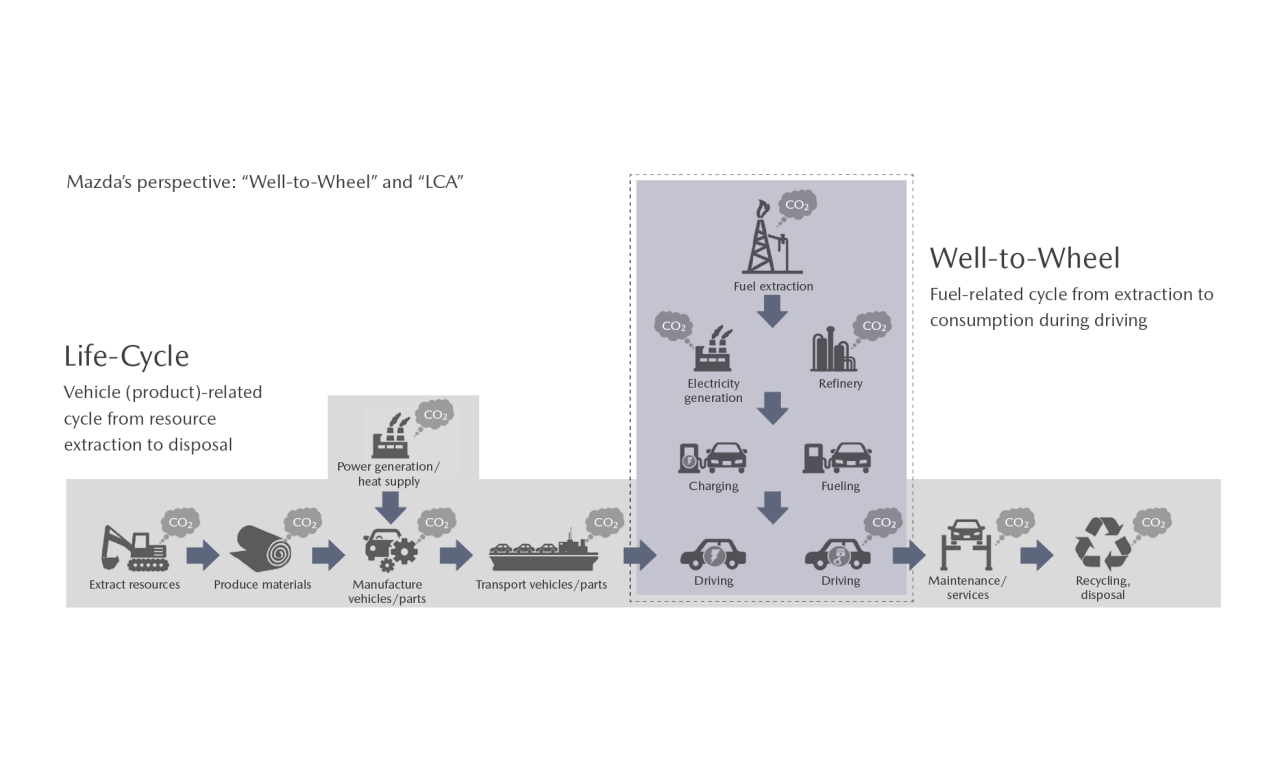

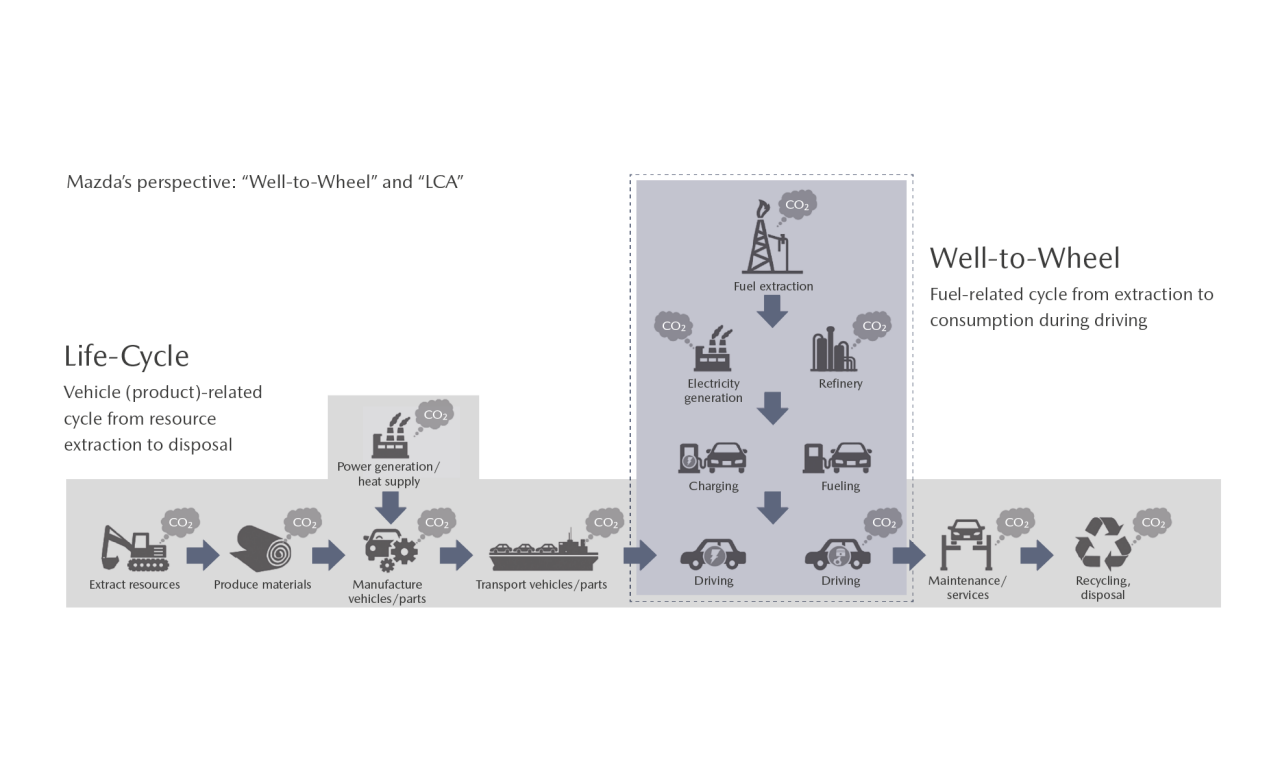

Mazda recognizes the importance of initiatives for reducing CO₂ emissions across the entirety of the vehicle life cycles. For this reason, the Company is adopting a well-to-wheel perspective and a life cycle assessment perspective. In FY March 2019, the Company assessed the CO₂ emissions across the life cycles of internal combustion engine vehicles and electric vehicles (EVs) in five regions around the world. These assessments found that the CO₂ emissions across the life cycles of such vehicles vary depending on regional conditions such as electricity-related circumstances, fuel economy and electric efficiency, and total travel distances. Based on the results of such assessments, the Company is adopting a Multi-Solution Strategy toward achieving fundamental reductions to CO₂ emissions by providing the most ideal option to match the needs of the energy sources, generation methods, and customers found in specific markets. Cross-supply chain efforts will be imperative to accomplishing our objectives, and the Company will thus be working toward these goals with the cooperation of local governments and other industries. Moreover, Mazda is making steady progress in line with its plans in carbon neutrality initiatives that contribute to the reduction of CO₂ emissions and the prevention of global warming in the areas of automobile creation (production), transportation (logistics), use (productions), and return (resource circulation).

CLIMATE CHANGE (ENDEAVORING TOWARD CARBON NEUTRALITY BY 2050)

- Basic Approach

- Targets

- Creation (Production)

- 1. Energy Conservation

- 2. Shift to Renewable Energy

- 3. Introduction of Carbon-Neutral Fuels

- Logistics (External Transportation)

- Use (Products)

- Vehicle Development for Achieving Carbon Neutrality

- Popularization of Carbon-Neutral Fuels

- Carbon Capture Technology Research

- Return (Resource Circulation)

Basic Approach

Life Cycle Assessments

Life cycle assessments entail calculating and assessing the environmental impact across the entire life cycle of a vehicle, which begins with raw material procurement and goes on to include manufacturing, use, recycling, and ultimately disposal. Mazda began conducting life cycle assessments in 2009 as a way to identify opportunities for reducing environmental impacts across the vehicle life cycle, and the Company is actively working to minimize these impacts at every stage. In addition, the Company carries out objective and reliable evaluations of new technologies that influence the environmental performance of vehicles based on methods that comply with international standards (ISO 14040 and ISO 14044).

Well-to-Wheel

Mazda approaches CO₂ emissions reductions from a well-to-wheel perspective that combines two perspectives. The first is well-to-tank emissions, which refers to emissions over the process of extracting (well) and refining fuel and then putting it in a vehicle's tank. The second is tank-to-wheel emissions, which occur when a vehicle's tank is filled with fuel and used to drive (wheel). Based on this perspective, we aim to reduce exhaust gas and CO₂ emissions from driving as well as greenhouse gas emissions from the series of processes beginning with fuel extraction.

【Related Article (Mazda Mirai Base)】

What is LCA? Sustainability Management at Mazda - The Road to Carbon Neutrality Episode 2

Targets

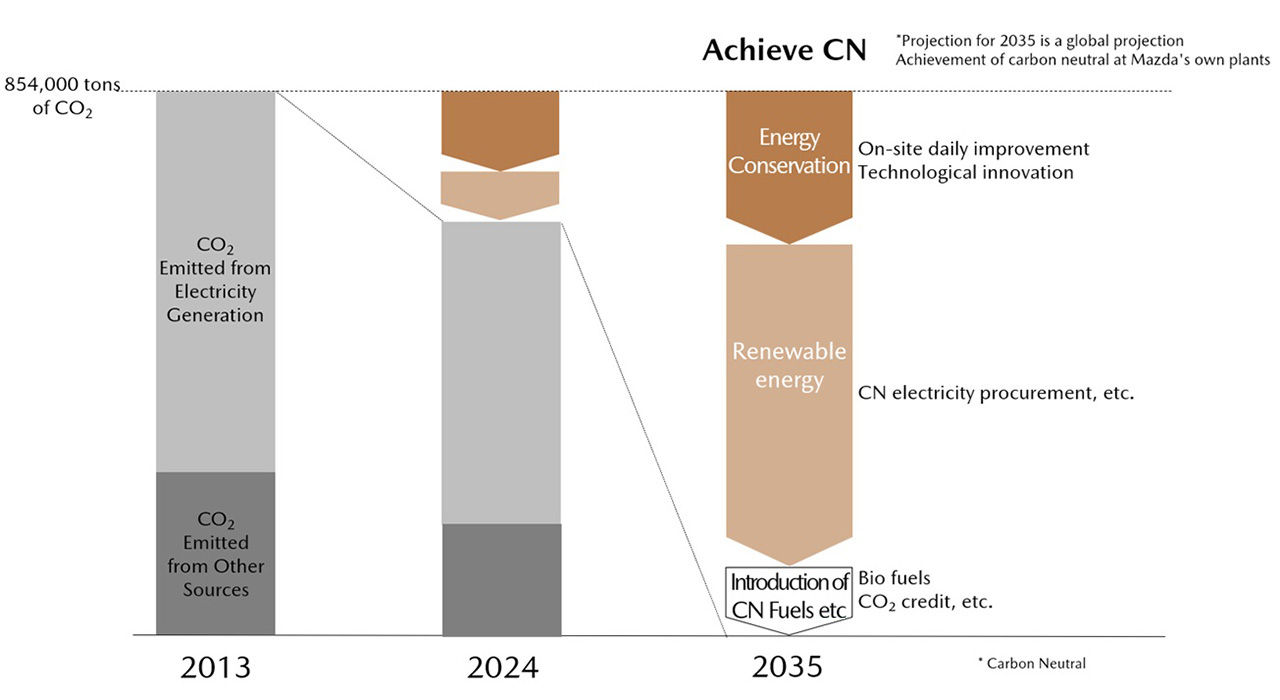

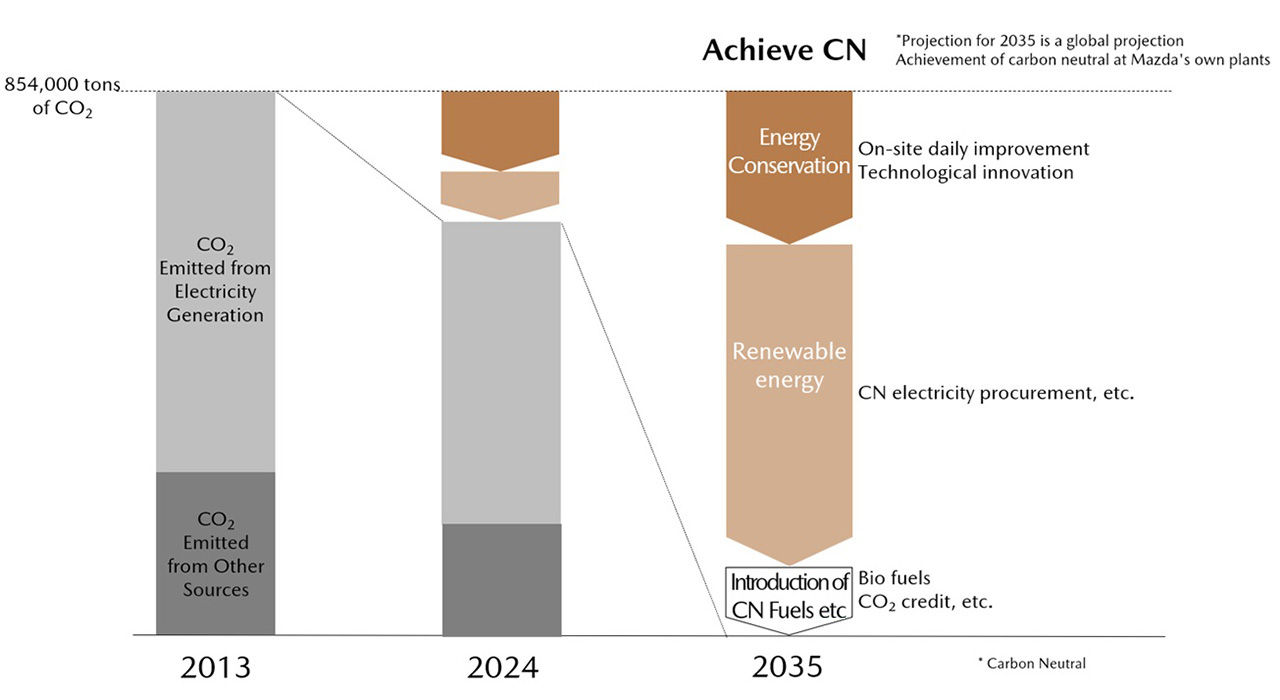

FY March 2031: Reduction of CO₂ emissions from domestic factories and operating sites

2035: Achieve carbon neutrality at Mazda's global factories

2050: Achieve carbon neutrality across the entire supply chain

As a milestone on its road to achieving carbon neutrality throughout the entire supply chain by 2050, Mazda will endeavor to achieve carbon neutrality at its factories worldwide by 2035.

In September 2025, we updated our road map and medium-term target for achieving carbon neutrality at Mazda plants and operating sites in Japan,*1 which account for approximately 75% of our global total CO₂ emissions. This update was meant to facilitate more flexible responses in light of trends in the alternative fuel procurement and technological advancements.

In accordance with this road map, Mazda switched the fuel used to supply the in-house power generation facilities at the Hiroshima Plant, Ujina District from the originally planned coal to ammonia. However, we now plan to transition to a gas cogeneration system*2 fueled by city gas produced using liquefied natural gas (LNG), a proven power generation technology, to more steadily pursue decarbonization. This system will allow us to undertake a phased shift toward hydrogen fuel, which is gaining attention as a carbon-neutral form of fuel, with only small-scale equipment renovations. In this manner, we look to promote decarbonization in step with society's future adoption of carbon-neutral fuels. Going forward, we will work to determine ideal specifications for this generation system through co-creation with Kawasaki Heavy Industries, Ltd. in order to achieve high energy efficiency while allowing for optimal energy management to be practiced based on actual factory operating conditions.

In conjunction with the introduction of this system, the coal-fired thermal power generation systems currently in operation at the Hiroshima Plant and the Hofu Plant are schedule to be decommissioned around 2030. This plan will be advanced together with the community as we enlist the support of local power producers HIROSHIMA GAS Co., Ltd. and The Chugoku Electric Power Co., Inc.

Moreover, the update to the road map entailed reassessing our interim CO₂ emissions reduction target for FY March 2031 and resulted in us announcing a new target of a reduction of 46% or more in comparison to FY March 2014 in line with the Japanese national target. This target replaces the prior target of a 69% reduction from the same year. The new target will guide Mazda's steadfast efforts toward achieving carbon neutrality.

*1 Sites including Mazda's Head Office and Hiroshima Plant (Aki-gun and Hiroshima City in Hiroshima Prefecture), Hofu Plant (Hofu City, Yamaguchi Prefecture), and Miyoshi Plant (Miyoshi City, Hiroshima Prefecture)

*2 Gas cogeneration systems use primary energy sources (fuel) to power gas turbines and engines in order to continuously generate multiple forms of secondary energy (electricity, steam, etc.).

Creation (Production)

To achieve carbon neutrality at its factories worldwide, Mazda is working together with municipal government agencies and other industries to advance initiatives based on three pillars: energy conservation, shift to renewable energy, and introduction of carbon-neutral fuels. At the same time, we are seeking out the optimal approach toward reducing emissions at overseas factories through initiatives modeled after those implemented in Japan.

Scope: Sites including Mazda's Head Office and Hiroshima Plant (Aki-gun and Hiroshima City in Hiroshima Prefecture), Hofu Plant (Hofu City, Yamaguchi Prefecture), and Miyoshi Plant (Miyoshi City, Hiroshima Prefecture)

1. Energy Conservation

Mazda is working to achieve Companywide improvements in operational productivity and efficiency while reforming the operating practices for production and infrastructure equipment, heightening efficiency, and promoting technological innovation to conserve energy. These initiatives are shared with business partners so that we can pursue energy conservation together.

【Statistics from FY March 2025】

- Reduction of total CO₂ emissions from domestic and operating sites*1 of 24% (649,000 t-CO₂)*2 compared with FY March 2014

- Reduction of 55.9% in emissions per unit of sales revenue (18.3 t-CO₂ / ¥100 million) compared with FY March 2014

Introduction of Low-CO₂-Emissions Technologies and Energy Conservation Initiatives by Area

| Materials | Material weight is reduced by using thinner cast and forged parts, and energy consumption is reduced by shortening forging cycle time and downsizing the capacity of melting and heat treatment equipment. |

|---|---|

| Processing and assemble | Conventional flexible production lines are being evolved to realize higher-efficiency, mixed-flow production while more efficient manufacturing is pursued by rationalizing, consolidating, and integrating production lines. |

| Pressing | The amount of scrap generated in manufacturing of press parts is reduced, and parts are retrieved from scrap to reduce the amount of steel sheets used. Meanwhile, a multi-pressing approach involving molding of several parts using a single die has been adopted, resulting in both consolidation of processes and reduction of energy consumption. |

| Painting |

|

Note: Mazda has introduced an internal carbon pricing system (framework for promoting low-carbon investment and policies via use of internally decided carbon pricing) as part of its efforts to prioritize measures that promise major contributions to CO₂ emissions reductions. This system currently uses a price of ¥9,100 per t-CO₂.

*1 Sites including Mazda's Head Office and Hiroshima Plant (Aki-gun and Hiroshima City in Hiroshima Prefecture), Hofu Plant (Hofu City, Yamaguchi Prefecture), and Miyoshi Plant (Miyoshi City, Hiroshima Prefecture)

*2 Market-based: Calculated using emissions factors provided in the Ministry of the Environment's greenhouse gas accounting and reporting system

2. Shift to Renewable Energy

Mazda plans to transition to a gas cogeneration system fueled by city gas produced using LNG for the in-house power generation facilities used at the Hiroshima Plant to facilitate a steady approach toward decarbonization. This system will make enable a phased shift toward hydrogen fuel requiring only small-scale equipment renovations and thereby allow us to pursue decarbonization in conjunction with society's future adoption of carbon-neutral fuels. In addition, the Company intends to decommission the coal-fired thermal power generation systems it is currently using by around 2030. At the same time, we are examining the possibility of expanding solar power use and adopting storage battery systems as we gradually decarbonize together with our partners and with the community.

Expansion of Solar Power Use

Solar panels have been installed at Mazda's Hiroshima Plant, and operation of a solar power generation system was started at these sites in July 2021. Electricity generated by this system is used to charge the batteries of the plug-in hybrid electric vehicles (PHEVs) produced at the plant and for other manufacturing processes

【Statistics from FY March 2025】

Generation of 1,723 MWh of power at Mazda's Head Office and Hiroshima Plant

A solar power generation system has been installed on the roof of the radio wave experiment building of the Miyoshi Plant. Electricity generated by this system is used to provide power and lighting for the building.

【Statistics from FY March 2025】

Generation of 26 MWh of power at the Miyoshi Plant

Affiliates have been systematically introducing solar power generation systems and purchasing low-CO₂-emissions electricity. In FY March 2025, a significant increase was seen in the use of electricity generated by solar power generation systems at overseas affiliates.

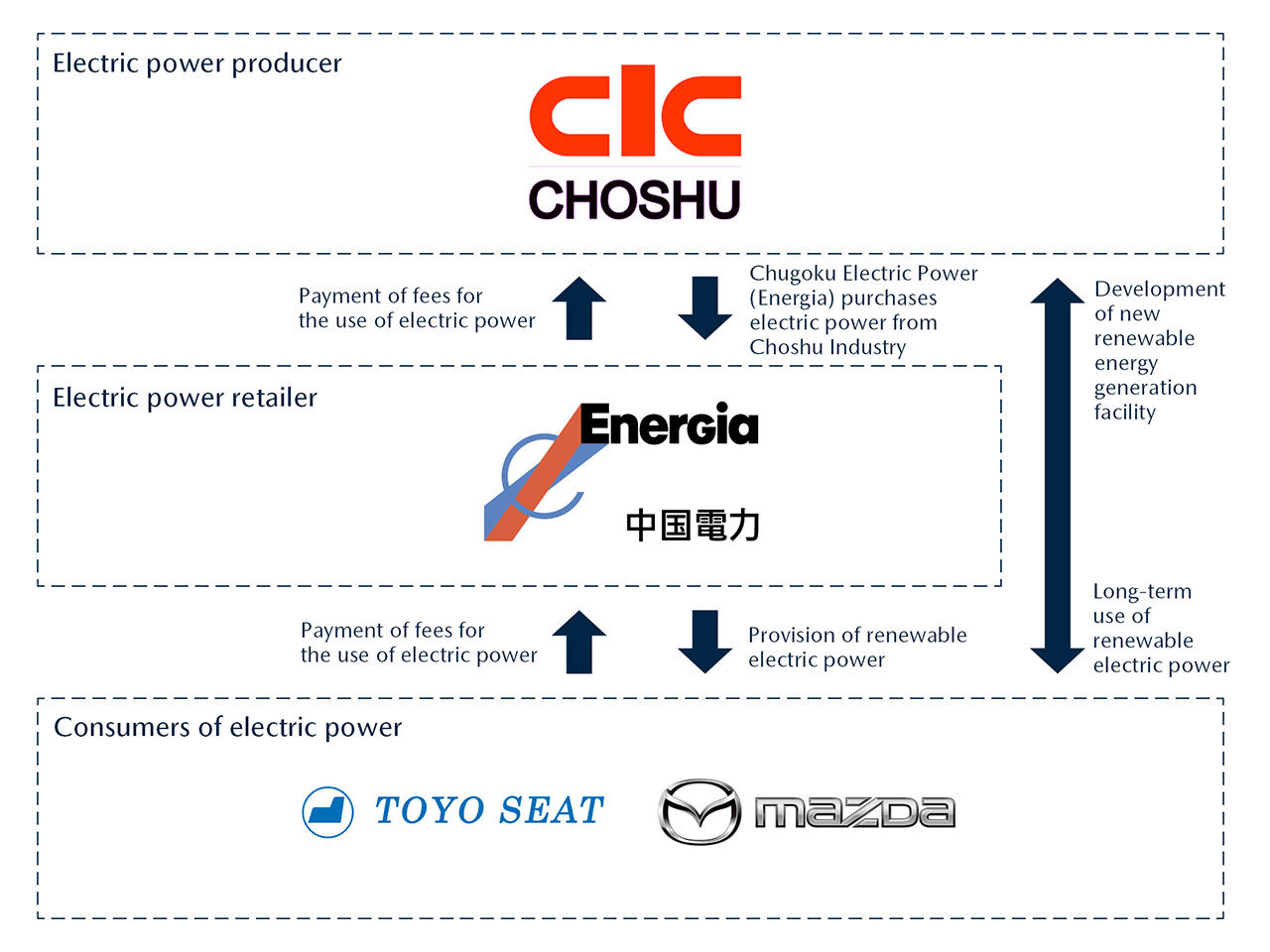

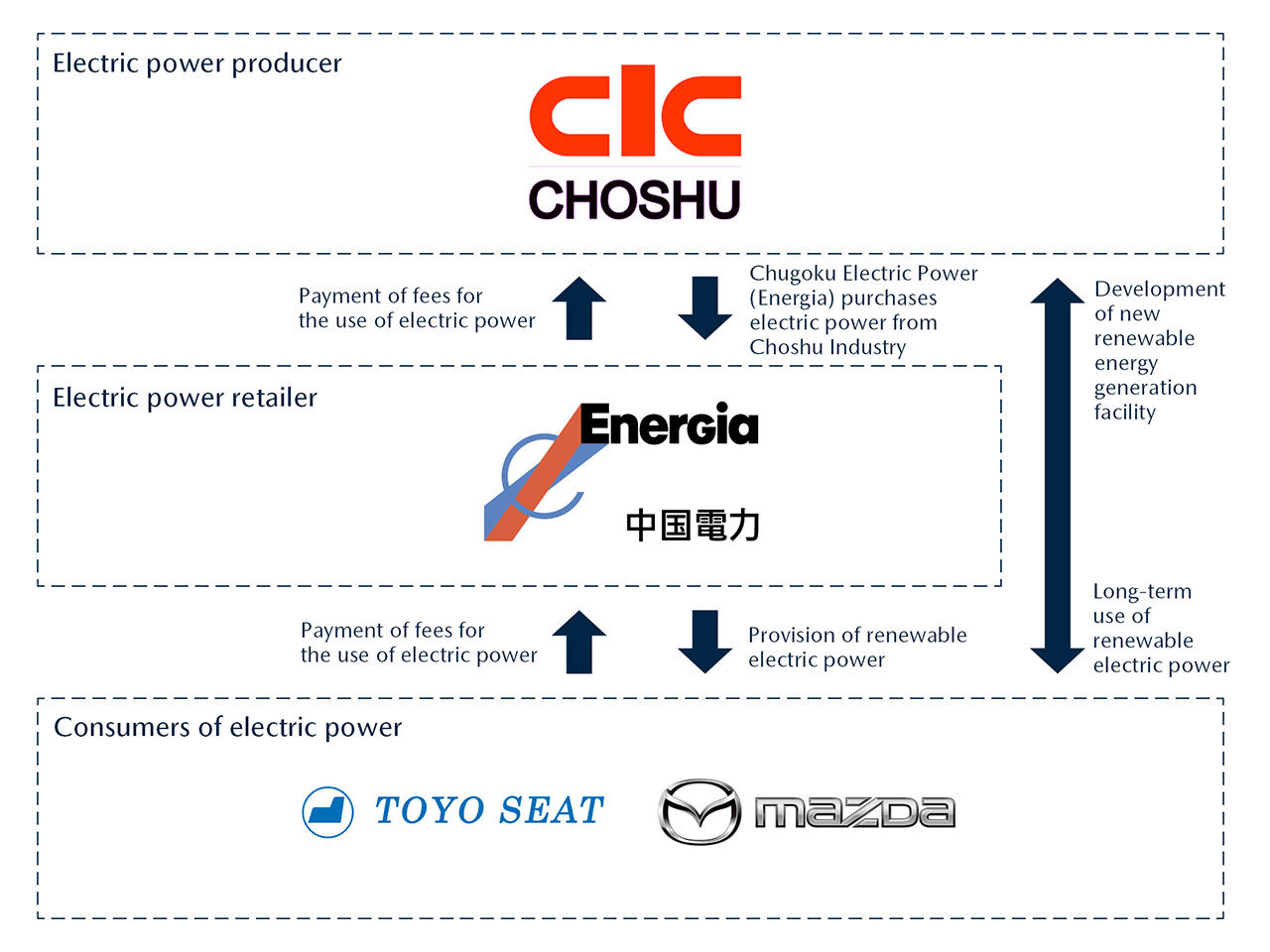

Conclusion of Off-Site Corporate PPAs Related to Solar Power Generation

Mazda prioritizes cooperation with local industries when it comes to introducing PPAs in conjunction with new renewable energy development projects. Accordingly, the Company invests in renewable energy generation through an approach that matches the characteristics of the regions in which we position our domestic bases. As Step 1 of this approach, in March 2023 Mazda concluded an off-site corporate PPA*1 with Toyo Seat Co., Ltd.; Choshu Industry Co., Ltd.; and The Chugoku Electric Power Co., Ltd. involving solar power generation.*2 This was the first instance of an off-site corporate PPA involving coordination among multiple power users in the Chugoku region of Japan. Based on this agreement, new solar power generation systems will be installed on idle land held by Choshu Industry and Mazda in the Chugoku region, for which Choshu Industry will act as the power generation business operator. The electricity generated by these systems will be sold to Chugoku Electric Power, which will then supply this electricity to Toyo Seat and Mazda as renewable energy. In April 2023, Chugoku Electric Power commenced the supply of approximately 4,900 kW of renewable energy generated by solar panels to plants and other places of business belonging to Toyo Seat and Mazda. These arrangements have reduced annual CO₂ emissions by approximately 2,610 tons. Going forward, we will move forward with on-site corporate PPA*3 and off-site corporate PPA plans, which call for increased coordination with business partners and other local businesses, as Step 2 of this approach. We will then go on to expand the scope of these efforts as a business advanced together with local industries, which will constitute Step 3.

【Related Article (Mazda Mirai Base)】

*1 An off-site corporate PPA is a long-term contract for the purchase of electricity under which a company producing electricity through solar power generation facilities agrees to provide power generated using those facilities to a designated user or users based in a location separate from the solar power generation facilities, supplying that power to them via an electricity transmission network operated by an electricity retailer.

*2 In 2022, Japan's Ministry of Economy, Trade and Industry provided subsidies to cover a portion of the expense of installing solar power generation facilities in cases where users of electricity coordinated with an electricity producer to build such facilities. These subsidies were intended to promote such collaboration and to encourage wider adoption of independent initiatives to establish renewable energy sources with the goal of contributing to a reliable, long-term supply–demand balance in energy use during the period up until 2030, thereby supporting the achievement of ambitious targets for the reduction of greenhouse gas emissions. The aforementioned PPA arrangement was applicable under this subsidy program.

*3 An on-site corporate PPA is a contract that involves a company installing solar power, wind power, or other renewable energy generation facilities on its premises and directly purchasing electricity generated by those facilities.

Expansion of Carbon-Neutral Electricity Supply and Demand in the Chugoku Region

Mazda believes that coordination with communities as well as with other companies, government agencies, and academic organizations is imperative to the ongoing expansion of renewable energy use. To facilitate such coordination, Mazda joined the Carbon Neutral Electricity Promotion Subcommittee, an expert subcommittee of the Chugoku Region Carbon Neutrality Promotion Council, in 2021. As a member of this subcommittee, the Company has worked with its collaboration partners to formulate a road map to help expand supply and demand for electricity generated from renewable energy sources. Mazda began verification tests aimed at putting this road map into practice in 2023 and is moving toward the implementation stage.

【Related Article (News Release)】

Utilization of Automotive Batteries

In August 2025, Toyota Motor Corporation and Mazda commenced a verification test that involves connecting the Sweep Energy Storage System* utilizing Toyota automotive batteries to the internal power systems at Mazda's Hiroshima Plant. This verification test is geared toward contributing to the development of battery ecosystems to support the stable procurement of critical resources and building a resilient supply chain, which is part of the issues that the Japan Automobile Manufacturers Association is addressing across the industry. Moreover, we aim to promote the sustainable reuse of batteries in Japan through this project. In the future, the storage system will be used to regulate power supply and demand from renewable energy, which fluctuates depending on weather and time of day, to contribute to carbon neutrality.

【Related Article (News Release)】

* The Sweep Energy Storage System rapidly switches power flow of batteries on and off, even when new batteries are connected to degraded or different capacity batteries.

3. Introduction of Carbon-Neutral Fuels

The process of creating automobiles involves the use of fuels, such as petroleum gas (gaseous fuel), gasoline and diesel oil (liquid fuels), and coke (solid fuel), in stages including research and development, transportation of people and parts in factories, and manufacturing of engines and vehicles. The use of such fuel results in emissions of CO₂. As such, it is crucial to introduce carbon-neutral fuels to replace fossil fuels for processes that cannot be performed using only electricity. The introduction of carbon-neutral fuel requires coordination across the fuel supply chain, which encompasses the production, transportation, storage, and use of fuel. Accordingly, the Company is pursuing such coordination. In cases where generating power from alternative fuel sources proves difficult, we will make use of J-Credits to promote forest preservation and reforestation in order to absorb CO₂ in the Chugoku region and other regions.

Carbon-Neutral Coke Initiatives

Demonstration Operation of Cupola Melting Furnace Fueled Entirely by Biomass

At Mazda's headquarters and Hiroshima Plant, cupola melting furnaces are used to melt plating sheet offcuts produced during the automobile body pressing process so that the resulting materials can be reused to produce cast parts. We are working to achieve the carbon-neutral operation of these furnaces, a feat that has yet to be accomplished anywhere in the world, by transitioning from fossil-derived coke to biomass-derived bio-coal briquettes by FY March 2031. In February 2025, Mazda was able to announce that it had succeeded in the verification operation of a cupola melting furnace fueled entirely by bio-coal briquettes created from coconut shells. We are currently moving forward with concrete initiatives for developing a supply chain in the Chugoku region spanning from the collection of biomass waste to the production of biomass fuel. Mazda thereby aims to develop schemes for the cyclical local production and consumption of energy to further contribute to the community and the invigoration of local industries.

【Related Article (News Release)】

Mazda Conducts Demonstration Operation of Cupola Melting Furnace using Biomass Fuel 100%

Carbon-Neutral Gasoline Initiatives

Participation in Research Association of Biomass Innovation for Next-Generation Automobile Fuels

In March 2023, Mazda announced that it would be joining the Research Association of Biomass Innovation for Next-Generation Automobile Fuels, an organization formed by ENEOS Corporation, Suzuki Motor Corporation, Subaru Corporation, Daihatsu Motor Co., Ltd., Toyota Motor Corporation, and Toyota Tsusho Corporation. As a member of this organization, we will work with other members to advance research and development of bioethanol fuel production technologies to expand the possibilities for carbon-neutral fuels that function as a viable option for contributing to carbon neutrality.

【Related Article (News Release)】

Mazda Joins Research Association of Biomass Innovation for Next Generation Automobile Fuels

Carbon-Neutral Diesel Fuel Initiatives

Underwriting of Convertible Bonds Issued by Euglena

In January 2023, Mazda decided to underwrite the unsecured convertible bonds to be issued by Euglena Co., Ltd. Through the underwriting, the Company will support Euglena's biofuels business aimed at expanding the use of next-generation biofuels. The next-generation biofuels produced by Euglena boast excellent sustainability since they do not compete with food production and do not cause deforestation, unlike conventional biofuels made from food crops such as corn. Moreover, these next-generation biofuels differ from conventional biofuels, such as bioethanol and fatty acid methyl ester,* in that they are hydrocarbon fuels similar to gasoline and diesel fuel. For this reason, the Company expects them to be able to completely replace petroleum-based fuels. Mazda is examining the possibility of procuring the next-generation biofuels to be manufactured by Euglena for use in logistics and other internal processes.

* Fatty acid methyl ester is a fuel produced using vegetable oils and animal fats. It is widely used as a form of eco-friendly diesel fuel due to its similarity to conventional diesel fuel.

Research on Microalgae

It is currently common to create next-generation biomass fuel with used edible oils, but it can be expected that there will be difficulties in securing such resources in the future. With the aim of achieving mass production of next-generation biofuels, Mazda is turning its attention to the mass cultivation of microalgae, which boast a high production capacity per unit area when compared to vegetable resources, which are used to produce edible oils. To facilitate such mass cultivation, the Company is currently promoting research on microalgae through industry-academia-government collaboration.

Microalgae absorb CO₂ and carry out photosynthesis and also have the characteristic of gaining nutrition from nitrogen and phosphorus and storing large amounts of lipids and proteins in their cells in addition to oils. Mazda is advancing research on utilizing this characteristic to clean wastewater produced during the automobile manufacturing process, which contains nitrogen and phosphorus, and to provide a source of nutrients for people. With the aim of recycling waste to produce new resources, in 2023 the Company began using outdoor microalgae cultivation facilities at its headquarters to verify the CO₂ reduction benefits and wastewater purification capabilities of microalgae.

Going forward, the Company will continue to pursue the various possibilities for microalgae with the goal of creating circular ecosystems that make the most of the warm climate and long hours of sunlight facing the Seto Inland Sea.

【Related Article (Mazda Mirai Base)】

Expansion of Next-Generation Biofuel Supply and Demand in the Chugoku Region

Mazda aims to develop supply chains in the Chugoku region that encompass the production, transportation, storage, and use of next-generation biofuels. To this end, the Company joined, as a leading member, the Carbon Neutral Fuel Promotion Subcommittee, which was established in June 2023 as an expert subcommittee of the Chugoku Region Carbon Neutrality Promotion Council created by the Chugoku Economic Federation. Together with partners in this subcommittee, we have formulated a road map to help expand supply and demand for next-generation biofuels and are preparing recommendations for government policy. The road map formulated by the subcommittee as well as the policy recommendation submitted in March 2025 will be used to guide joint public–private efforts to expand supply and demand for next-generation biofuels.

J-Credits

With the goal of contributing to the realization of a carbon-neutral society, Mazda has concluded a sales and purchase agreement with Mitsui & Co., Ltd., covering J-Credits generated through appropriate forest management. The credits are certified by the Japanese government under the J-Credit Scheme. As the first company to use J-Credits, Mazda will purchase credits based on the absorption of CO₂ through forest preservation initiatives over an eight-year period spanning from FY March 2023 to FY March 2030. The Company decided to purchase J-Credits with the aims of contributing to CO₂ absorption and decarbonization in the Chugoku region, where it is based, while also helping protect and nurture local forest resources, preserve water sources, prevent landslides, and protect biodiversity.

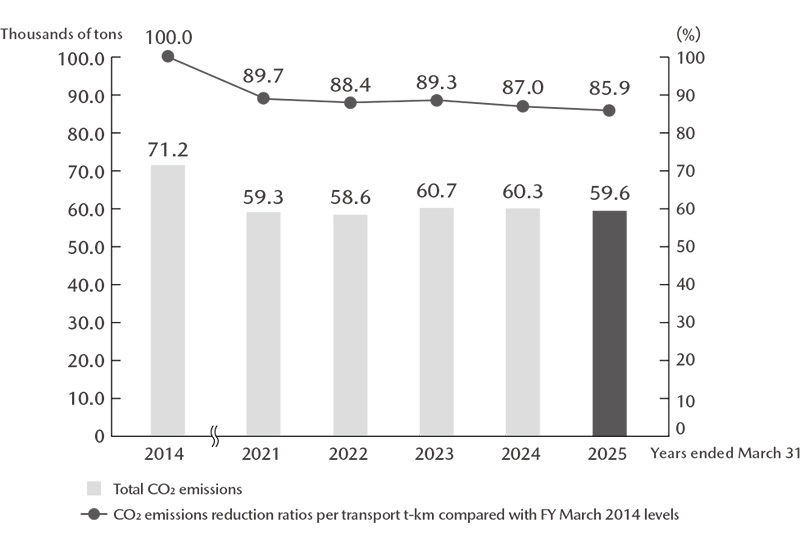

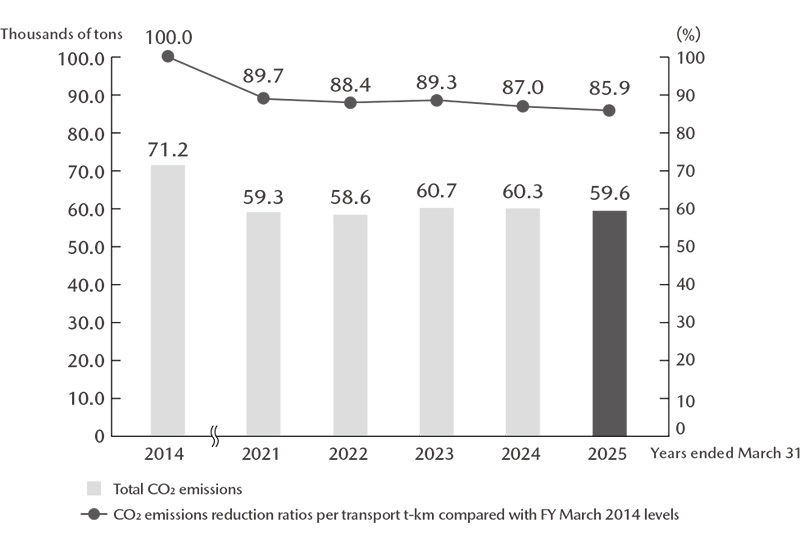

Logistics (External Transportation)

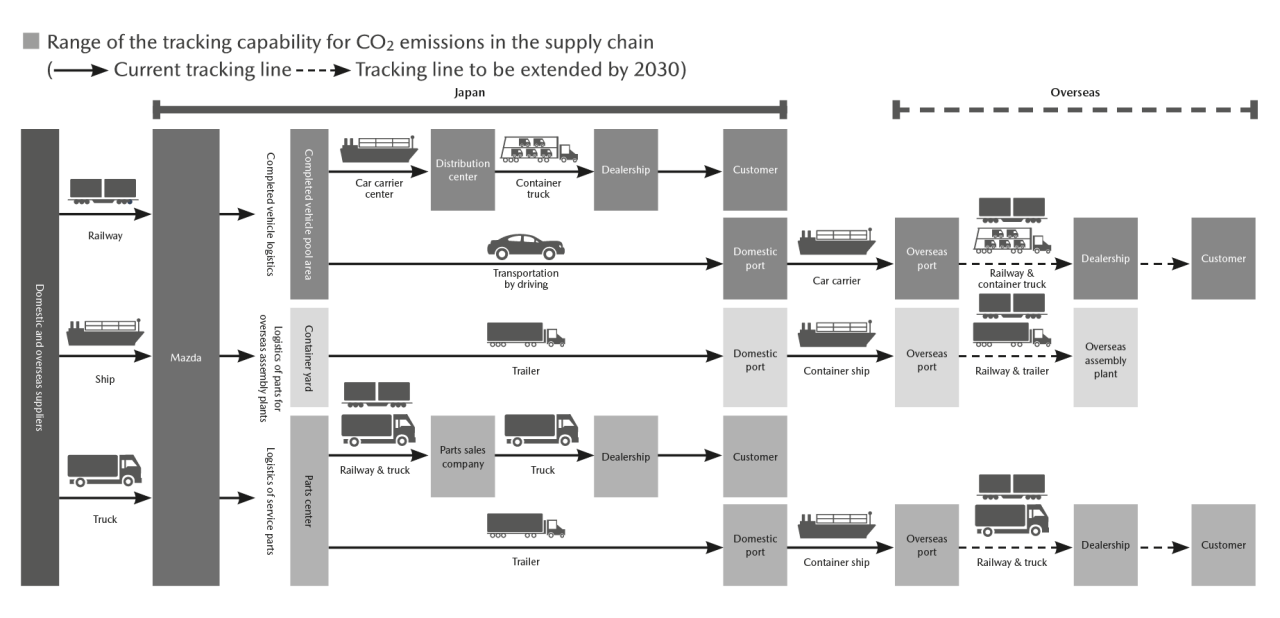

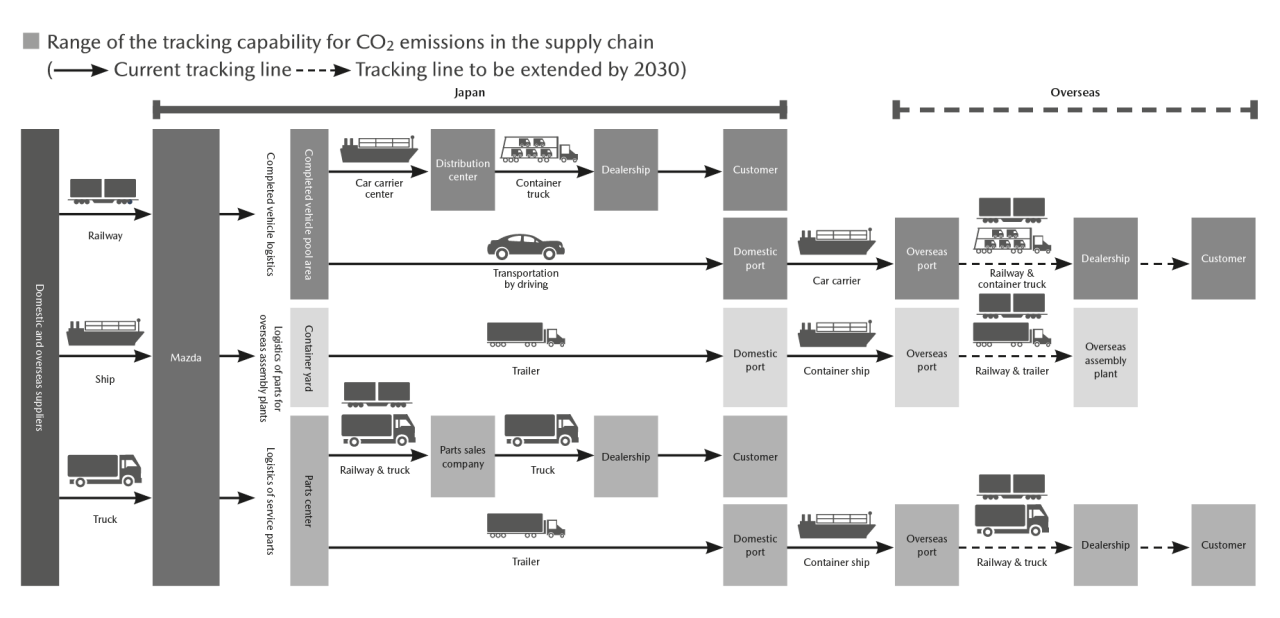

Mazda is working together with logistics companies, dealerships, and other automobile manufacturers in its external transportation of vehicles, parts, and other items. We thereby seek to supply customers with the volumes of vehicles and parts they require, delivered with the precise timing they expect. The Company is also looking to reduce CO₂ emissions during product shipment through highly efficient logistics across the entire supply chain in order to contribute to more sustainable logistics practices. In 2021, we began collecting data on Scope 1 and Scope 2 CO₂ emissions by Tier 1 suppliers as well as emissions associated with logistics for deliveries by these suppliers to Mazda. In addition, we established an award system to honor the efforts of our suppliers in FY March 2023.

【Statistics from FY March 2025】

- Total domestic transportation volume of approximately 476 million ton-kilometers

- Reduction of CO₂ emissions per ton-kilometer by 14.1% compared with FY March 2014 levels

Logistics CO₂ Emissions Volumes and Reductions (Japan)

Logistics Tracking

Mazda takes steps to track the logistics processes used for the transportation of completed vehicles, parts to domestic and overseas factories, and service parts so that this information can be used to guide reductions in environmental impacts and CO₂ emissions as well as energy savings through improved transportation efficiency.

Scope of Supply Chain CO₂ Emissions Tracking

1. Completed Vehicles

Mazda is promoting shared transport with other companies to improve efficiency in the marine transport of completed vehicles to Japan while also examining the possibility of utilizing alternative fuel sources. For marine transport of completed vehicles to overseas destinations, the Company seeks to ensure that ships are fully loaded to transport more vehicles and actively utilizes eco-friendly liquefied natural gas (LNG) tankers. Furthermore, we are moving forward with discussions and investigations with a range of partners—including shipping companies, logistics companies, energy-related companies, and local government agencies—to explore the technologies, fuels, equipment, and other methods of contributing to greater decarbonization benefits in the future.

2. Transportation of Parts to Domestic and Overseas Factories

In 2016, Mazda introduced the Cloud-based Transportation/Delivery Progress Management Service for Logistics Operators* for use with the trucks utilized for transportation of parts to domestic factories. Through the use of this system, we are working to improve transportation efficiency and quality while also reducing environmental impacts and the burden placed on drivers. We have also revised cargo handling procedures in conjunction with the introduction of this system to heighten truck turnover rates and reduce truck waiting time at factories.

Meanwhile, Mazda has adopted a straight logistics approach for certain parts shipped to overseas factories. In this approach, parts are packaged at the production sites of businesses partners in Japan before being loaded in containers at nearby logistics sites and then onto ships at the neighboring ports. We are also utilizing returnable containers for transportation of parts to factories to reduce waste. These containers are now being used for engines, transmissions, and vehicle body parts. Moreover, we are also examining the possibilities of expanding transportation via freight trains, fully loading trailers, and introducing biofuel alternatives for delivery trucks. At the same time, the Company is introducing new standard containers for parts to be transported in containers to overseas factories. These containers make it possible to eliminate the empty space inside the containers while also reducing the number of containers and the number of transportation truck services needed. The Company is also working to reduce inventories of surplus parts by shipping the parts to overseas plants in conjunction with their production schedules. Meanwhile, Mazda is engaged in discussions with shipping companies regarding the potential future use of container carriers that utilize alternative fuels with lower CO₂ emissions.

* The Cloud-based Transportation/Delivery Progress Management Service for Logistics Operators was developed by DOCOMO Systems, Inc.

3. Transportation of Service Parts

Mazda has been increasing its use of transportation methods with lower emissions for the transportation of service parts within Japan. We are also utilizing large returnable containers, originally introduced to transport service parts overseas, to improve the loading efficiency for transportation via freight trains in Japan. In addition, the introduction of semi-trailers has made it possible to transport larger loads of cargo with a single truck, contributing to higher loading efficiency. These initiatives have helped reduce the number of truck services used for transportation and thereby contribute to lower CO₂ emissions.

Meanwhile, the Company relocated production of replacement bumpers and some sheet metal parts shipped to overseas factories from the Hiroshima Plant to the Tokai region to enable these items to be sent directly overseas, without transporting them to the Hiroshima Plant first, via the Nagoya Port. Furthermore, in 2023 Mazda relocated production of replacement bumpers previously produced in Japan to the United States, the primary market where they are used.

Use (Products)

Power sources, environmental regulations, and customer needs can vary substantially by country and region. To accommodate these differences while achieving business growth and advancing effective carbon neutrality initiatives based on life cycle assessment and well-to-wheel perspectives, Mazda is advancing its multi-solution approach, which entails responding to market characteristics and customer lifestyles by providing the ideal options from among battery electric vehicles (BEVs), PHEVs and other hybrid electric vehicles and internal combustion engine vehicles.

Vehicle Development for Achieving Carbon Neutrality

To realize its goal of reducing CO₂ emissions and raising the average fuel economy of its vehicles, Mazda has formulated the Building Block concept, which enables the efficient development of superior technologies by layering fundamental technologies atop one another in stages. Based on this concept, the Company is rolling out a Multi-Solution Strategy through efficient development and production via measures such as comprehensive planning methodologies and common architecture. Through the Building Block concept and process innovations, such as model-based development and Mazda Monozukuri Innovation, the Company will efficiently utilize its limited management resources to offer products and technologies that exceed customers' expectations.

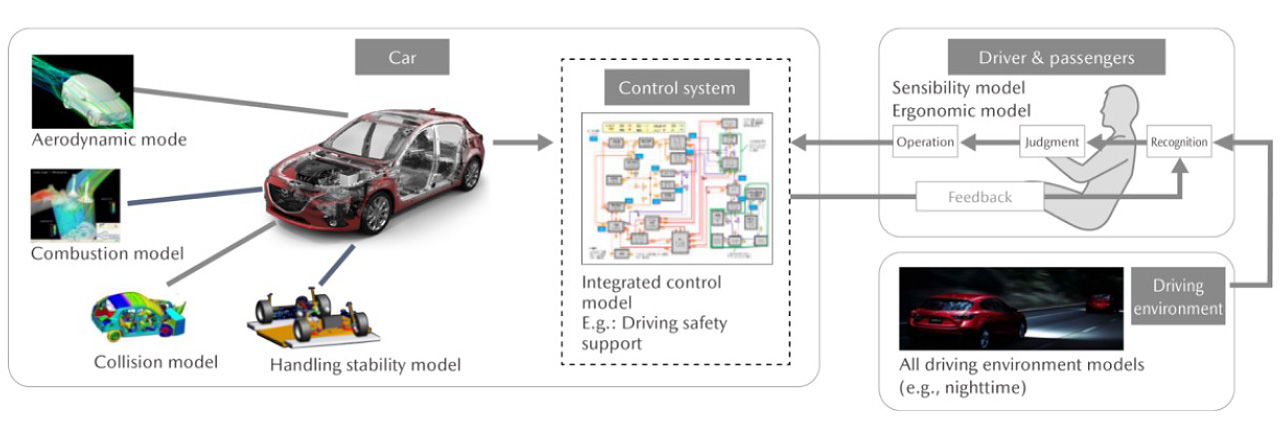

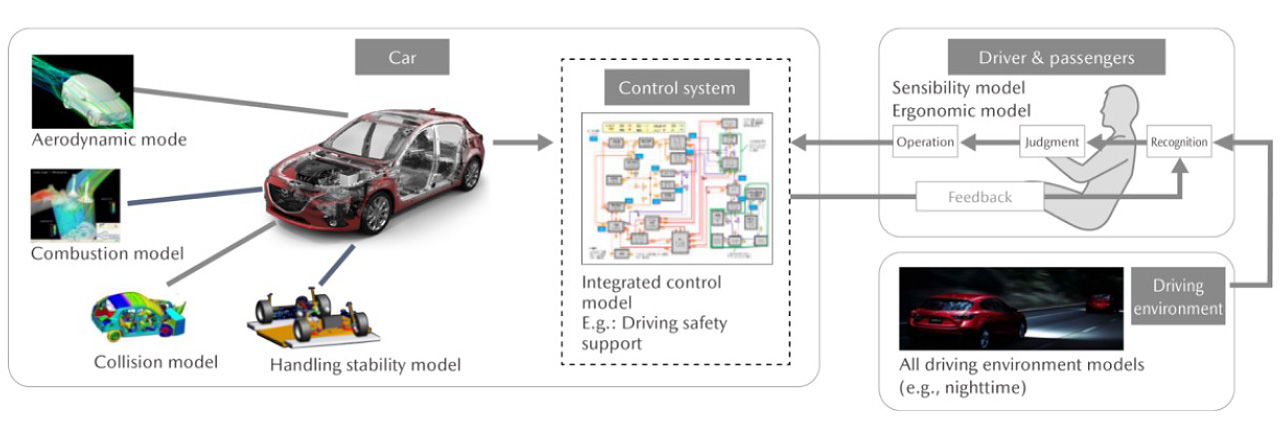

Model-Based Development

Automobiles are being called on to provide increasingly advanced and diverse functions, while vehicle architecture and control systems are becoming more and more complex. Model-based development, which uses computers to efficiently replicate development processes, is essential to keep developing complex systems quickly and with limited resources. Model-based development involves creating computer models of vehicles, control systems, drivers, passengers, driving environments, and other development subjects and conducting development via computer simulation, making it a highly efficient development method. Mazda is carrying out model-based powertrain and vehicle development through simulations for stages spanning from design to vehicle evaluation. The Company thereby strives to reduce the number of prototype parts and actual unit verification processes in order to develop complex, highly sophisticated technologies and products quickly and with minimum resources while also ensuring quality. Mazda believes that to further promote model-based development, universities working on cutting-edge technologies and automobile manufacturers and suppliers that cooperate in manufacturing must build upon the SURIAWASE 2.0 concept, which is aimed at enhancing development efficiency by using virtual models across the engineering chain. To that end, the Company is playing an active role in activities by the Japan Automotive Model-Based Engineering center (JAMBE). In this manner, the Company is engaging with domestic automobile manufacturers and business partners to spread the SURIAWASE 2.0 concept throughout the Japanese automotive industry.

Overview of Model-Based Development

Mazda's Electrification Strategies Leading Up to 2030

Mazda recognizes that the period leading up to 2030 will be a time of transitioning to electrified vehicles. We are therefore promoting electrification based on the Management Policy up to 2030 and through our Multi-Solution Strategy for furnishing flexible responses to diversifying customer needs and environmental regulations. Moreover, the Company is enacting its Lean Asset Strategy to improve corporate value in a manner that takes advantage of its small scale. Specifically, this strategic will entail increasing the extent to which we use existing assets to facilitate the timely development, production, and launch of diverse products and electrification technologies.

【Related Information (MULTI-SOLUTION BRIEFING 2025)】

Given the trends in electrification-related policies and regulations seen around the world, we project that the portion of automobiles on the global market represented by EVs will rise to between 25% and 40% by 2030. Seeking to respond flexibly to changes, such as those pertaining to regulatory trends, consumer needs, electrified vehicle acceptance levels, and social infrastructure development, Mazda is advancing electrification together with partners through the following three-phase electrification approach.

Phase 1 (2022–2024): Enhance technology development for the age of electrification

- Full utilization of existing multiple electrification technology assets

- Introduction of large products to improve earning power with PHEVs, mild hybrid electric vehicles, and other products that deliver excellent environmental and driving performance while advancing full-fledged development of BEVs

Phase 2 (2025–2027): Transition to electrification

- Introduction of new hybrid systems to reduce CO₂ emissions through improvements in fuel economy

- Start of global launch of BEVs

- Creation of competitive next-generation electric drive unit through coordination with core electric drive unit operations

- Establishment of joint venture with partners in Chugoku region to create highly efficient production technology development, production, and procurement frameworks

- Conclusion of joint development agreements and establishment of joint ventures to develop the inverters that are core elements of electric drive systems

- Conclusion of joint development agreements and establishment of joint ventures for researching and cultivating motor technologies

- Procurement of batteries from partner companies while advancing ongoing in-house advanced battery technology research and development project adopted by the Green Innovation Fund Project

Phase 3 (2028–2030): Full-scale launch of BEVs

- Advancement of full-fledged launch of BEVs

- Focus on electrification including possible investment in battery production based on the extent of changes in the operating environment and progress in strengthening financial base

Electrification Transition Road Map

Popularization of Carbon-Neutral Fuels

Each country and region faces radically different conditions in terms of energy-related circumstances, power sources, and BEV adoption rates. This reality underscores the importance of providing customers with a diverse range of options. Mazda is developing engine technologies that allow for the accommodation of various carbon-neutral fuels based on this recognition. We have been participating in the Super Taikyu Series of car races since late 2021 with the goal of using these events as a venue for testing these engine technologies. Mazda enters two vehicles in these races: the MAZDA SPIRIT RACING 3 Future concept (No. 55) and the MAZDA SPIRIT RACING RS Future concept (No. 12). Moreover, we have partnered with Kawasaki Heavy Industries, Subaru, Toyota, and Yamaha Motor Co., Ltd. to accelerate the development of such technologies.

MAZDA SPIRIT RACING 3 Future concept (No. 55) is fueled by hydrotreated vegetable oil, a next-generation biodiesel fuel that is widely available in Europe. This vehicle is able to operate without significant changes to engine hardware while also realizing a 90% reduction in CO₂ emissions across the stages of creating, using, and transporting vehicles when compared to conventional diesel fuel.

Since the 2023 season, MAZDA SPIRIT RACING RS Future concept (No. 12) has been using a renewable fuel synthesized from ethanol derived from non-edible biomass. This vehicle has thus been a vessel for verifying the viability of technologies for withstanding the extreme conditions presented by car races without changing engine hardware. Moreover, we are racing this vehicle with the E20 low-carbon fuel produced by ENEOS in the Fuji Super TEC 24 Hour Race, the third race of ENEOS Super Taikyu Series 2025 Empowered by BRIDGESTONE, and have been able to confirm the performance and reliability of this fuel.

Going forward, Mazda will continue to verify its technologies through events like the Super Taikyu Series while also expanding the scope of fuels it explores to include such options as microalgae-derived biofuel and e-fuel.

| Participating Vehicles | MAZDA SPIRIT RACING 3

|

MAZDA SPIRIT RACING RS

|

|---|---|---|

| Class | ST-Q |

ST-Q |

| Base vehicle | MAZDA3 |

MAZDA ROADSTER |

| Engine | Diesel engine |

Gasoline engine |

| Fuel used | Diesel Alternative |

Gasoline Alternative |

Carbon Capture Technology Research

Mazda is advancing research and development of technologies for capturing the CO₂ emitted from vehicles to contribute to the realization of a carbon-neutral society. Microalgae and other biofuel materials absorb CO₂ as they grow via photosynthesis, and the CO₂ emitted during the combustion of these fuels is no more than the CO₂ absorbed through this process. Accordingly, in theory, biofuels do not contribute to increases in the total CO₂ in the atmosphere, when excluding the CO₂ emitted during production and processing.

This process of producing biofuel requires energy, and CO₂ may be emitted to generate this energy. The amount of CO₂ emitted for energy generation is estimated to be around 10% that emitted during fuel combustion. Accordingly, biofuels contribute to a 90% reduction in total CO₂ emissions when compared to fossil fuels.

Moreover, the CO₂ emitted during the production of biofuels can be offset by capturing the CO₂ released through the combustion of this fuel. This entails decarbonization technologies similar to direct air capture. However, as exhaust gas contains concentrations of CO₂ significantly greater than the air, this higher concentration means that capturing CO₂ from exhaust gas is more efficient and requires less energy and space than other capture methods. If more than 10% of the CO₂ emitted during the combustion of biofuels could be captured, it would offset the CO₂ emitted during the production process and mean that, in theory, vehicles using biofuel could contribute to greater reductions in the amount of CO₂ in the atmosphere the more they drive, becoming effectively carbon negative. This potential for decarbonization is something that is unique to internal combustion engines and not found in BEVs.

Future challenges for these technologies include finding ways to adjust the temperature of exhaust gas to a level at which CO₂ can be captured more efficiently, address increases to vehicle weight or decreases to in-vehicle space that could result from the introduction of capture equipment, and use the captured CO₂. Possible uses for CO₂ include applications pertaining to the cultivation of microalgae, use as material for creating e-fuel, and greenification applications. By combining such technologies, Mazda is committed to providing the joy of driving while supporting sustainable mobility.

【Related Article (Mazda Spirit Racing)】

Return (Resource Circulation)

Automobiles are made of various materials. Plastic, for example, is a material derived from petroleum, and therefore releases CO₂ into the atmosphere when burned to produce heat energy after disposal. To reduce CO₂ emissions associated with the disposal of automobiles, Mazda designs its vehicles to be easier to disassemble and also develops material and parts technologies for expanding the reuse and recycling of resources.

【Detailed Information (Sustainability Website)】