Under its Safety and Health Creed, Mazda aspires to develop a proactive and enjoyable workplace* to ensure the health and safety of employees. To this end, we are advancing the One Mazda Movement for an Enjoyable Workplace, a program that entails participation of all employees worldwide, based on the perspectives of people, workplaces, and frameworks. The Company believes that the development of a proactive and enjoyable workplace will help invigorate employees and improve their work performance, and thereby contribute to the exercise of its corporate philosophy.

OCCUPATIONAL HEALTH AND SAFETY

Basic Approach

* Mazda defines a proactive and enjoyable workplace as one where intensive problem-solving activities are implemented, taking into account the characteristics of the relevant divisions, and where individual employees work harmoniously as a team led by their manager to contribute to the invigoration of individual employees and their organizations.

Safety and Health Creed

For workers, safety and health are essential assets. Our people are our most valuable resource, and we are committed to keeping them safe.

One Mazda Movement for an Enjoyable Workplace

Policy

Realize a proactive and enjoyable workplace by accomplishing safety and health activities initiated by individuals and divisions

Slogan

Safety and health first in One Mazda, 24 hours a day

Three pillars of activities

1) Development of human resources with heightened sensitivity

2) Creating optimal systems (promoting standardization)

3) Development of a safe, secure, and comfortable working environment

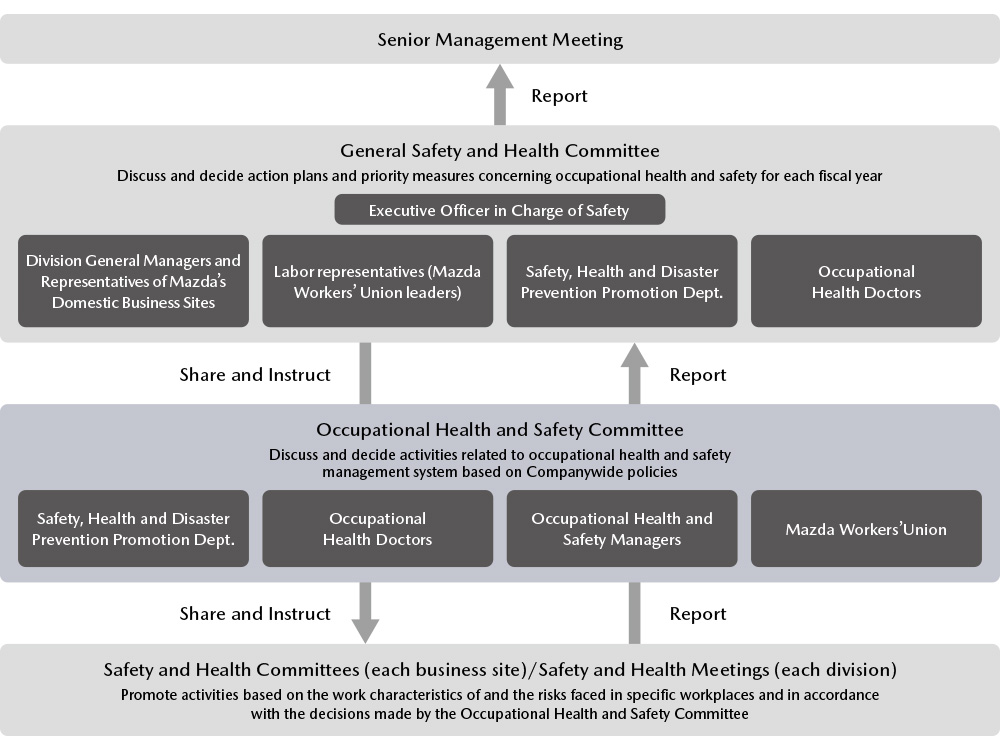

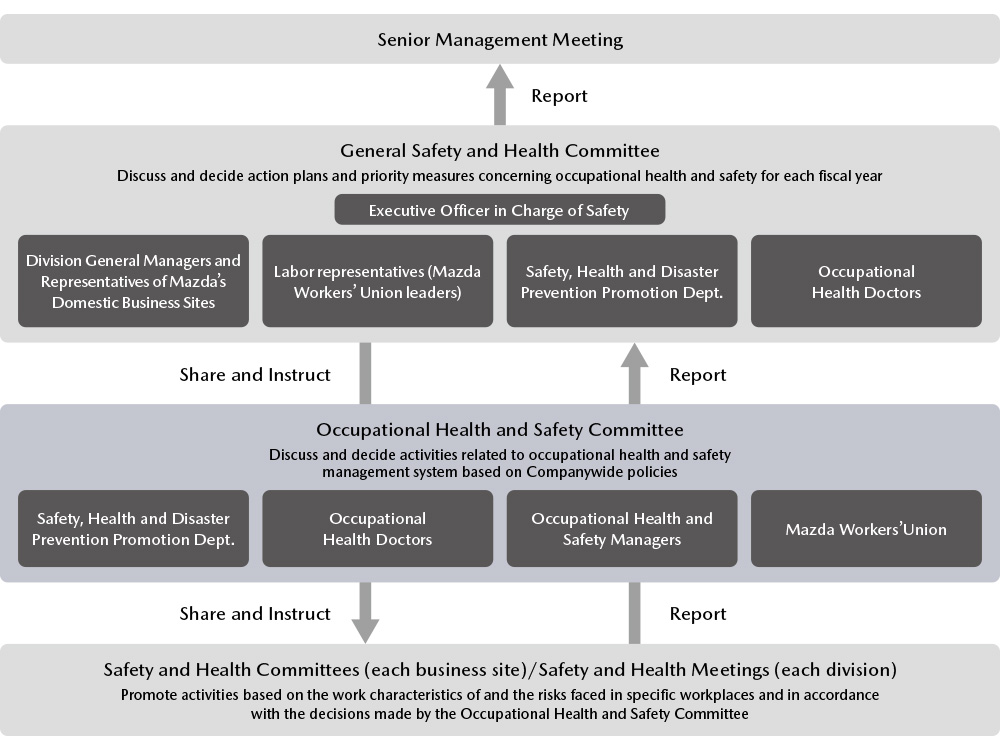

Frameworks

Mazda has established the General Safety and Health Committee, comprised of members of management (the executive officer in charge of safety and division general managers) and labor representatives (Mazda Workers' Union leaders). The committee members meet to discuss action plans and priority measures concerning occupational health and safety for each fiscal year. Based on the decisions made by the committee, operating base and division general managers promote occupational health and safety activities, taking into account their respective work characteristics and risks. In FY March 2026, Mazda revised its occupational health and safety promotion framework to facilitate more autonomous, efficient, and effective activities. As part of this revision, all divisions have appointed one middle manager to serve as their occupational health and safety manager. In addition, we organize monthly meetings of the Occupational Health and Safety Committee to discuss and decide activities related to occupational health and safety based on Companywide policies. In this manner, the Company is promoting initiatives that incorporate a health and productivity management perspective. Furthermore, safety and health committees are assembled at the workplace level while safety and health meetings are arranged at division level to promote activities based on the work characteristics of and the risks faced in specific workplaces and in accordance with the decisions made by the Occupational Health and Safety Committee and the tasks identified for the respective division.

Occupational Health and Safety Promotion Frameworks

Initiatives

Occupational Health and Safety Management System

An occupational health and safety management system is a framework for protecting the health and safety of employees and ensuring peace of mind in the workplace and for maintaining business continuity and improving productivity through systematic management via a plan–do–check–act (PDCA) cycle. Mazda implements an occupational health and safety management system with the aim of promoting voluntary and continuous occupational health and safety management for the purpose of reducing the potential risks of work-related accidents, enhancing overall levels of occupational health and safety, and achieving the industry's highest level of workplace safety in Japan. Furthermore, the Company evaluates procedural and facility risks that can easily lead to serious accidents, creates mechanisms to prevent accidents before they happen, and works to improve its performance in regard to occupational health and safety management.In FY March 2026, Mazda incorporated concepts based on ISO 45001 into its occupational health and safety management system and revised its PDCA cycle, frameworks, and processes relating to occupational health and safety management.

【Statistics from FY March 2025】

| FY March 2025 | Target | Average for Japanese Manufacturing Industry* | |

|---|---|---|---|

| Number of serious or fatal occupational accidents | 0 | 0 | - |

| Total injury frequency rate | 0.44 | 0.3 | - |

| Lost-time injury frequency rate | 0.11 | 0.05 | 1.30 |

Risk Assessments

Mazda conducts annual risk assessments of all divisions to identify and evaluate the potential risks of disasters, illnesses, and fires. The Company also implements appropriate countermeasures and conducts other activities to assess risk and improve workplace safety. Similarly, the Company carries out specialized chemical and machinery risk assessments when introducing new chemical substances or machinery to facilitate fundamental safety measures. For the management of chemicals, Mazda is compiling a database of safety data sheets*1 and is utilizing a system that enables it to evaluate risks from the perspectives of hazardousness and exposure.

Occupational Health and Safety Education and Training

Improving education and training programs are a central pillar of Mazda's occupational health and safety activities. Through these programs, we aim to develop human resources with heightened sensitivity toward occupational safety and health. The Company places particular emphasis on training to enhance employees' risk sensitivity and organizes safety education seminars,*2 risk simulation training,*3 and risk prediction training for all divisions, including those related to production, development, management, and administration. We also support Group companies in Japan and overseas, suppliers (Toyukai Affiliated Corporation*4), and partner companies within the Company premises in conducting education and training programs on safety and health in order to develop safety-conscious human resources across the Mazda Group.

*1 A safety data sheet is a document used when chemical substances and chemical mixtures are transferred or provided to others to supply information on their physical properties, potential risks, and harmfulness as well as instructions for safe use of these chemical substances.

*2 Safety education seminars feature panel exhibitions showing a timeline of Mazda's safety activities that summarize past serious accident cases and safety activities that Mazda has implemented so far to help employees reflect on the Company's safety activities and past accidents, raise their awareness, and obtain new knowledge, which will be helpful to safety management in the future.

*3 Risk simulation training is intended to improve employees' sensitivity toward risk through simulations of various potential risks in their workplaces.

*4 Toyukai Affiliated Corporation is a voluntary organization established in 1952 by Toyo Kogyo Co., Ltd. (currently Mazda Motor Corporation) and 20 partners with transactional relationships with the Company. This organization currently consists of 63 members. The Company offers advice and support to these members from the perspective of safety by providing safety information and inviting members to safety training provided by Mazda.

Coordination with Group Companies

Mazda offers proactive support to Group companies in Japan and overseas by such means as holding regular meetings, sharing activity plans and information, and providing educational materials to help address safety and health issues. ISO 45001 certification has been obtained by Changan Mazda Automobile Co., Ltd., Changan Mazda Engine Co., Ltd., and Mazda Powertrain Manufacturing (Thailand) Co., Ltd. In addition, other plants implement occupational safety and health management systems based on ISO 45001 or other equivalent standards. We work to make continuous improvements throughout the entire Group to such management systems.