Automobile manufacturers are aspiring to reduce exhaust gas emissions and improve the fuel efficiency of vehicles, both of which are tasks related to the natural environment and our everyday lives, and to help protect the safety and security of society while complying with relevant regulations. Mazda is also committed to ensuring that it can continue to coexist with a bountiful, beautiful earth into the future, and we are advancing ongoing initiatives to develop exhaust gas reduction technologies and lower usage of chemical substances in order to achieve this goal.

PREVENTION OF POLLUTION

Basic Approach

Initiatives

Cleaner Emissions

Cleaner Gas Emissions

Mazda is committed to mitigating air pollution from exhaust gas. To this end, the Company is actively developing low-emissions vehicles and launching vehicles that comply with the emissions regulations of the respective countries and regions.

Emissions Reduction Technologies

Mazda pays attention to global movements toward tighter control of exhaust emissions and fuel economy, market expansion due to rapidly growing emerging countries, and depletion of scarce resources. The Company has developed its unique high-performance, three-way catalytic converters and soot (particulate matter) oxidation catalyst, which it uses to reduce the use of precious metals and help to clean exhaust gases.

Latest Emissions Reduction Technologies

■Gasoline engines

Mazda uses a system based on a three-way catalytic converter to clean emissions from both its conventional 2.5-liter straight-4-cylinder engine and its 3.3-liter straight-6-cylinder gasoline turbo engine. Combined with improved fuel control technologies that increase the speed at which the catalyst activates after starting or restarting the engine, this system enables Mazda to clear the strict emissions regulations of different countries and regions, including the super-ultra-low-emission vehicle 30 (SULEV30) regulations of the United States.

■Diesel engines

To clean emissions from its 3.3-liter straight-6-cylinder diesel turbo engine, Mazda uses a system based on oxidation catalysts that also utilizes ceramic filters able to catch, collect, and clean soot. Making use of a proprietary distribution-controlled partially premixed compression ignition (DCPCI) technology developed in pursuit of ideal combustion conditions, as well as larger displacement, this affordable system does not require a nitrogen oxide (NOx) purification catalyst to achieve clean emissions that easily clear Japan’s Real Driving Emission (RDE) regulations.

Chemical Substance Management

Proper Management of Chemical Substances and Heavy Metals

Mazda publishes Management Standards for Environmentally Hazardous Materials specifying substances and heavy metals for which use in parts and materials that it purchases is subject to restrictions (prohibited substances and substances for which reporting is required) as part of its efforts to properly manage the use of such hazardous materials.

Collection and Management of Automotive Parts Materials

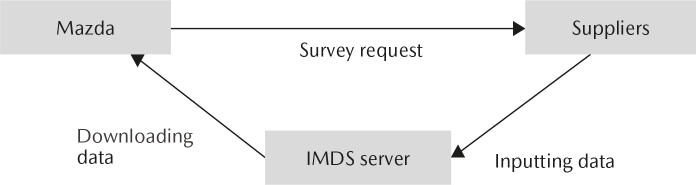

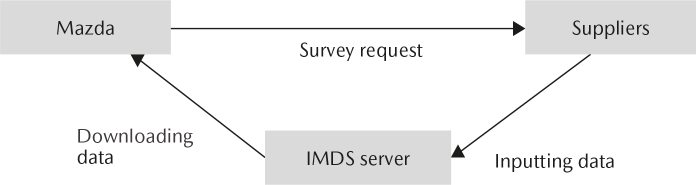

Mazda is working across its entire supply chain to appropriately manage the use of environmentally hazardous materials, such as lead, mercury, hexavalent chromium, and cadmium. As part of this process, the Company gathers information on the materials from suppliers using a standardized international material data system (IMDS).

Measures Related to Application of the IMDS

- The Company has developed and published a guideline that helps suppliers to correctly input IMDS data.

- The data gathered through the IMDS is used to calculate the Company’s vehicle recycling rate and to comply with various regulatory regimes for chemical materials, such as Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) in Europe.

How IMDS Works

Reduction of VOCs in Vehicle Cabins

To maintain a comfortable cabin environment, Mazda is committed to reducing the use of volatile organic compounds (VOCs) such as formaldehyde, toluene, and xylene, which have been implicated as possible causes of sick building syndrome.

■ In new models, starting with the Demio launched in 2007 (named the Mazda2 overseas at time of launch in 2007), Mazda is reducing VOCs in the main materials used in the cabin, such as plastics, paints, and adhesives, thereby conforming with the indoor aerial concentration guidelines established by Japan’s Ministry of Health, Labour and Welfare. (The CX-60, introduced in FY March 2023, followed the same guidelines.)

Adoption of Fuels that Reduce Environmental Burdens

Mazda is continuing efforts to reduce the emission of sulfur oxides (SOx), NOx, dust and soot, fine particles, vapors, and VOCs. In addition, the Company is shifting from the use of fuel oil to the use of city gas for fuel and making other efforts to actively adopt materials that reduce its environmental burdens.

VOC Reductions: Body-Painting Lines

As part of its efforts to reduce use of VOCs, Mazda has developed and subsequently introduced low-VOC paints for use with the Three Layer Wet Paint System, the standard process at major plants in Japan and overseas, and with the Aqua-Tech Paint System that delivers world-leading environmental performance. We have also implemented measures to achieve improved efficiency in thinner recovery for cleaning.

【Statistics from FY March 2024】

Reduction of VOC emissions from vehicle body paint in body-painting lines to 13.3 g/㎡

Reduction of Emissions of PRTR-Listed Substances

Mazda will continue efforts to reduce emissions of Pollutant Release and Transfer Register (PRTR)-listed substances as it moves forward with initiatives such as the introduction of the Aqua-Tech Paint System into the painting process and improvements to the efficiency of thinner recovery for cleaning.

【Statistics from FY March 2024】

Reduction of 512 tons in emissions of substances that are designated under the PRTR Law* into water systems and the atmosphere (reduction of 81% from FY March 1999)

Environmental data(Emissions of PRTR-listed substances)

* Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof