In order to promote environmental initiatives within the ISO 14001 scope of certification, the Company has implemented the Mazda Environmental Policy.

ENVIRONMENTAL MANAGEMENT

Basic Approach

Mazda Environmental Policy

Basic Policy

Through business activities that coexist with local communities and society, we will realize a carbon-neutral and recycling-oriented society.

Action guidelines

(1) Mazda will strive to recycle resources, reduce energy consumption, introduce renewable energy, and conserve biodiversity.

(2) Mazda will promote the use of environmentally friendly products and services by providing products and services whose life cycle was considered.

(3) Mazda will not only comply with environmental laws and regulations, but also consider the environmental impact of its corporate activities on local communities and society and ensure a comfortable environment of the society of the future.

(4) Mazda will raise the environmental awareness of each employee and contribute to the realization of a sustainable society through the Company's entire corporate activities, while placing importance on the appropriate disclosure of information and mutual communication.

Initiatives

Establishment of Environmental Management Systems

Mazda is promoting the establishment of environmental management systems across its entire supply chain and in all Group companies. The purpose of these systems is to facilitate more effective eco-friendly business activities based on ISO 14001 and other standards.

【Statistics from FY March 2025】

- Acquisition of ISO 14001 certification by Mazda and 14 of 15 Group manufacturing companies in Japan and overseas

- Promotion of receipt of certification under EcoAction 21 (EA21),* an environmental management system, by domestic directly operated dealerships and owner-managed dealerships; acquisition of certification at a total of 113 dealerships comprised of 23 dealerships for the Mazda/Mazda Enfini sales channel, 89 dealerships for the Mazda Autozam sales channel, and the Mazda Chuhan (as of March 31, 2025)

* EA21 is a simplified environmental management system established by Japan's Ministry of the Environment for application at companies of various scales, such as small to medium-sized companies.

List of ISO 14001-Certified Production and Business Sites

Domestic Production and Business Sites

| Hiroshima district | Hiroshima Plant | June 2000 |

| Miyoshi Plant | ||

| Hofu Plant | Nishinoura district | September 1998 |

| Nakanoseki district (Expand) | September 1999 | |

| Tokyo Headquarters | September 2016 | |

| Mazda R&D Center Yokohama | ||

| Proving Grounds (Mine, Kenbuchi and Nakasatunai) | ||

| Osaka Corporate Sales Office | ||

Four Domestic Consolidated Subsidiaries (Excluding Sales Companies)

| Mazda E&T Co., Ltd.*1 | June 2000 |

| Mazda Ace Co., Ltd.*1 | June 2000 |

| Mazda Logistics Co., Ltd.*1 | June 2000 |

| Kurashiki Kako Co., Ltd. | December 2001 |

Four Domestic Equity-Method Affiliates

| Toyo Advanced Technologies Co., Ltd.*2 | June 2000 |

| Japan Climate Systems Corporation |

May 2000 |

| Yoshiwa Kogyo Co., Ltd. | April 2002 |

| MCM Energy Service Co., Ltd.*3 | June 2008 |

Five Overseas Production Sites (Consolidated Subsidiaries and Equity-Method Affiliates)

| AutoAlliance (Thailand) Co., Ltd.*4 |

May 2000 |

| Changan Mazda Automobile Co., Ltd.*4 | December 2008 |

| Changan Mazda Engine Co., Ltd.*4 | February 2009 |

| Mazda Motor Manufacturing de Mexico, S.A. de C.V.*5 | December 2014 |

| Mazda Powertrain Manufacturing (Thailand) Co., Ltd.*5 | November 2016 |

*1 Some or all of the organizations at each of the companies acquired ISO 14001 certification in the certification scope of Mazda.

*2 The company received ISO 14001 certification within the scope of Mazda's certification. As a separate business facility, the company individually acquired the certification in March 2016. However, as a separate company, the company acquired re-certification in April 2017, resulting in the exclusion of the company from the certification scope of Mazda.

*3 Although the company was within Mazda's scope of certification, it acquired the certification on its own in March 2013.

*4 Equity-method affiliate

*5 Consolidated subsidiary

Implementation of Environmental Audits

To confirm that environmental management systems, such those based on ISO 14001, EA21, and other standards, are functioning effectively, both internal audits and external audits are carried out annually at Mazda and all domestic and overseas Group companies that have obtained certification. The results of internal audits and external audits are reported to senior management, and any problems are swiftly and appropriately rectified.

Issues Identified by External Audits Based on ISO 14001 Standards*

| FY March 2021 | FY March 2022 | FY March 2023 | FY March 2024 | FY March 2025 | |

|---|---|---|---|---|---|

| Serious noncompliance issues | 0 | 0 | 0 | 0 | 0 |

| Minor noncompliance issues | 0 | 0 | 1 | 0 | 0 |

| Areas with room for improvement | 5 | 5 | 8 | 6 | 12 |

* Scope of audits: Mazda Motor Corporation

Elimination of Sensory Pollution

Sensory pollution includes noise, vibration, and odors that have a sensory or psychological impact on people. Mazda recognizes that clearing legal regulations may not be enough to prevent noise, vibration, and odors from annoying the surrounding individuals. For this reason, the Company is systematically stepping up measures to alleviate the causes of such pollution as well as measures to improve noise insulation and odor removal.

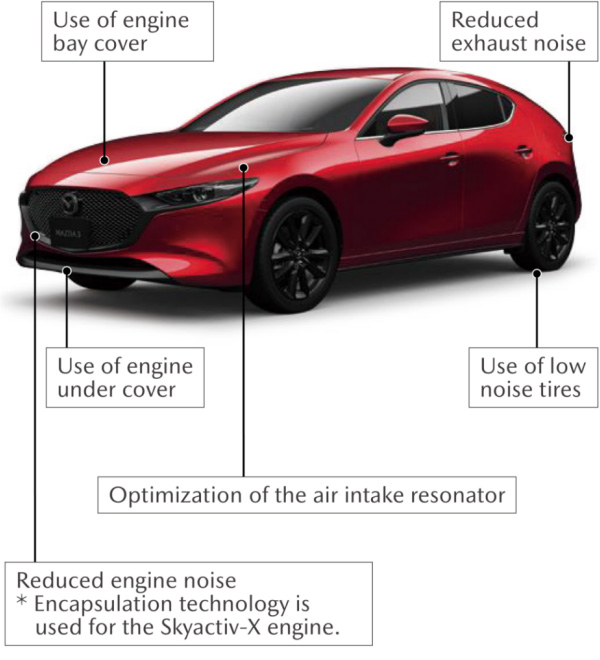

Reduction of Vehicle Noise

Mazda has established its own noise standards for all vehicle models that are even stricter than the most recent legal requirements. Compliance with said standards is pursued to reduce road traffic noise from Mazda vehicles. The Company has also been actively developing technologies to reduce the three major types of vehicle noises: engine noise, air intake and exhaust system noise, and tire noise.

Example of Anti-Noise Measures (Mazda3)

Environmental Risk Management

Environmental Monitoring

Drills are conducted at individual production sites and offices to prepare to respond to accidents, incidents of environmental pollution, and other risks while regular environmental monitoring is performed in relation to air and water pollution and other environmental risks.

【Statistics from FY March 2025】

| Environmental Monitoring Category | Monitoring Target | Items Monitored | Monitoring Frequency |

|---|---|---|---|

| Air quality | Boilers, melting furnaces, heating furnaces, drying furnaces, etc. | Sulfur oxides, nitrogen oxides, soot, volatile organic compounds, and hydrogen chloride (5 items) | Approx. 280 times per year |

| Water quality | Treated wastewater | Cadmium, cyanide, organic phosphorus, lead, hexavalent chromium, etc. (43 items) | Approx. 1,700 times per year |

| Noise and vibration | Site boundaries | Noise level and vibration level (2 items) | 12 times per year |

| Odors | Site boundaries, etc. | Odor index (1 item) | 12 times per year |

| Waste | Slag, sludge, scrap metal, etc. | Cadmium, cyanide, organic phosphorus, lead, hexavalent chromium, etc. (25 items) | Approx. 100 times per year |

The Company is taking appropriate actions and is implementing measures to prevent recurrence of environment-related legal violations and complaints.

【Statistics from FY March 2025】

| Mazda Motor Corporation | Group Companies | |||||

|---|---|---|---|---|---|---|

| Number of incidents | Details | Response | Number of incidents | Details | Response | |

| Legal violations | 0 | - | - | 0 | - | - |

| Complaints | 0 | - | - | 4 | Noise (3), others (1) | Issues to address causes, etc., completed |

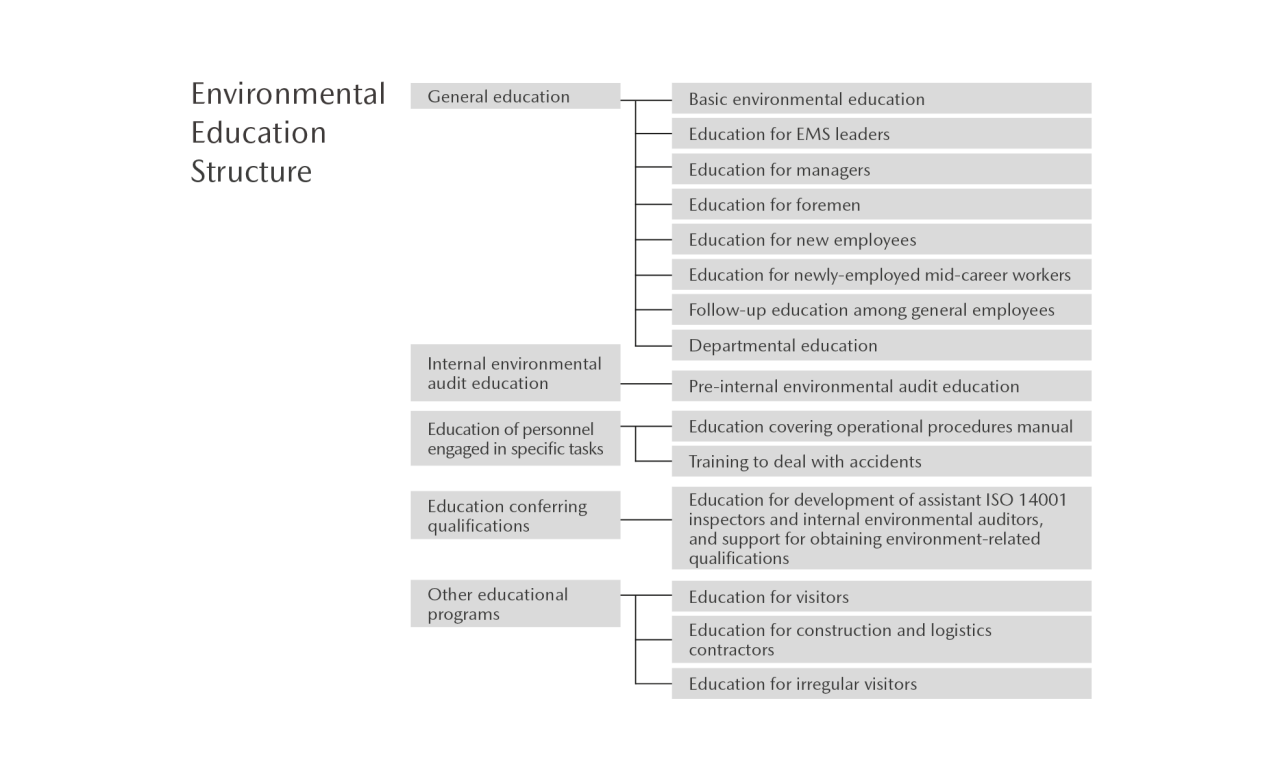

Environmental Education Programs

As part of its environmental management system, Mazda implements environmental education programs—covering topics such as global environmental issues, trends inside and outside Japan, the Company's environmental initiatives, and environmental preservation activities at different workplaces—for all employees once a year and for environmental management system leaders twice a year. The Company also encourages employees to obtain environment-related public qualifications and offers support for employees working toward these qualifications, including financial support through the Mazda Flex Benefit System.*

* The Mazda Flex Benefit System is a selective benefit system. Individual employees can seek the type of assistance that most suits them by choosing from a number of preset benefit options within the scope of allocated points.

Qualifications that Employees Are Encouraged to Obtain:

- Qualified Person for Energy Management

- Head pollution control supervisor

- Air and water pollution control supervisor (Class 1 to 4)

- Noise- and vibration-related pollution control supervisor

- Dust and particulate pollution control supervisor (Specified, General)

- Dioxide pollution control supervisor

- Special management-designated industrial waste disposal supervisor

- Environmental Society Test (Eco Test)

- Environmental management system auditor

- Internal environmental auditor

- Environmental measurer

- Construction environment hygiene control engineer

Environmental Education Structure

Environment-Related Accident Prevention Activities

Oil Spill Prevention and Traffic Safety Campaign

Together with Mazda Logistics Co., Ltd. and several truckload transportation companies, Mazda Motor Corporation conducts an awareness-raising campaign aimed at improving traffic safety awareness and preventing oil spills on roads during vehicle delivery. In this campaign, which is held twice a year, awareness-raising leaflets are distributed to drivers of vehicles delivered to the Hiroshima Plant and the Hofu Plant. In doing so, the Company strives to improve such drivers' awareness of the environment and safety and create a system to ensure that employees can make a quick and appropriate response in the event of an accident. As part of its efforts to prevent oil spills from occurring, Mazda has established a record system* that consolidates databases on the maintenance status of each vehicle and information on past environmental defects and presents this information in a visual format. The system began operation in March 2021, and introduction of the system had been completed at all participating truckload transportation companies as of March 31, 2024. In FY March 2025, a series of briefings was held for the purpose of encouraging the adoption of this system at other transportation companies. Going forward, the Company will strive to utilize this system as an effective tool for preventing oil spills.

Awareness-raising leaflets being distributed

* The record system entails integrated management of various transportation vehicle information in the possession of truckload transportation companies to allow for alert messages to be sent to these companies as necessary. Information recorded by this system includes vehicle models, registration dates, travel distances, and dates of legally mandated and annual inspections and maintenance.