- Contribute to a future sustainable Earth by providing multi-solution to mitigate climate change

- Contribute to a society where everyone feels safe to move freely by providing technology that proactively enhances our well-being

- Contribute to each person’s joy of living by delivering moving and emotional experiences

March 18, 2025 Mazda Announces “Lean Asset Strategy” that Realizes Electrification of Multi-Solution

2030 VISION

TO BE A CAR-LOVING COMPANY THAT CREATES MOVING EXPERIENCES THROUGH THE JOY OF DRIVING

MANAGEMENT POLICY UP TO 2030

BASIC MANAGEMENT POLICY

As the automotive industry undergoes a massive transformation, more diverse products are introduced to the market due to the evolution of digital technology and the entry of new players in the automotive industry. As various functions and services come to be provided by connecting a variety of items via IoT technologies, the value that vehicles can offer to society is expected to continue to change and increase.

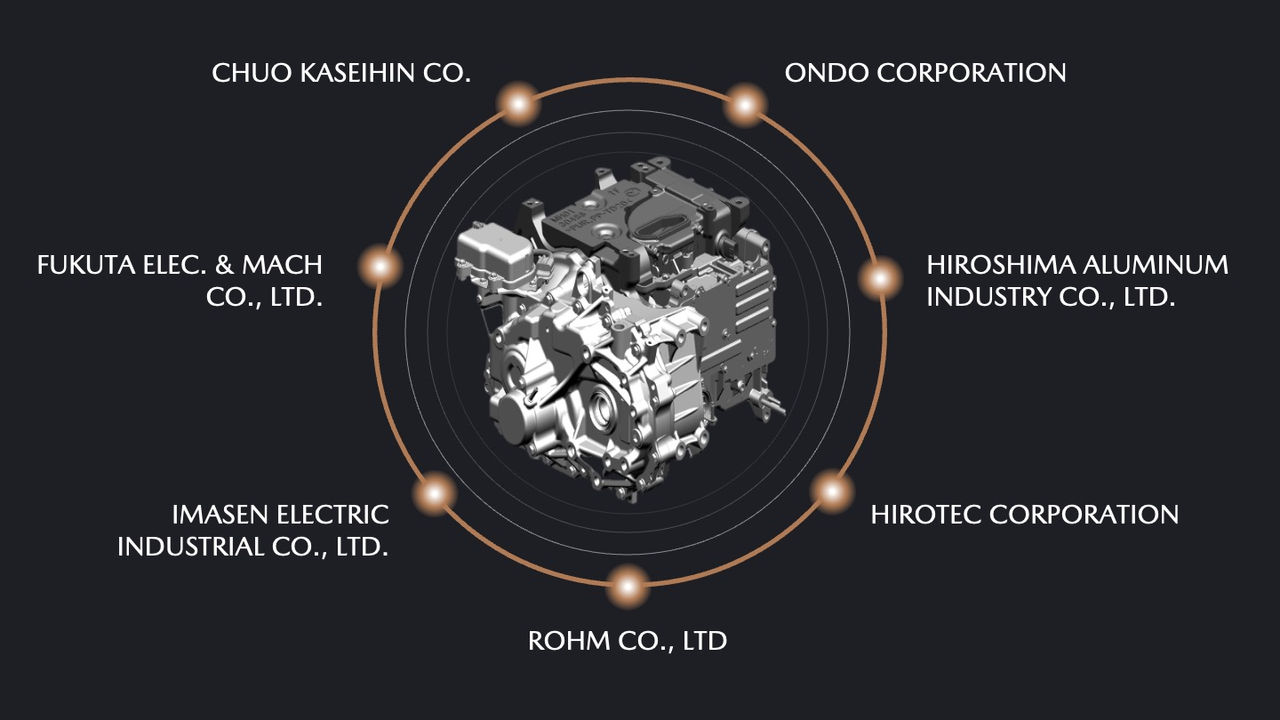

To respond to social changes such as these, Mazda will complement ongoing technology development activities with contributions to curbing global warming and to the realization of an automotive society that offers safety and peace of mind achieved by working with its many corporate co-creation partners to unite their knowledge and passion.

Moreover, Mazda wants to be able to create moving, exciting experiences in people’s everyday movement and to offer happiness that can be shared with others. To this end, based on its approach toward brand value management, the Company will contribute to society by turning the joy of driving into a wider joy of living.

ROADMAP

FOUR KEY INITIATIVES FOR SHAPING THE FUTURE

Based on the principles of co-creation and coexistence, Mazda values co-creation with partners when promoting collaboration projects with them. At the same time, the Company will build a framework for developing new technologies and resolving issues and further refine its own strengths. To do so, it is implementing initiatives in the following four areas.

Key Initiatives 1:

CARBON NEUTRALITY

Mazda has announced that it will endeavor to achieve carbon neutrality across its entire supply chain by 2050. To accomplish this goal, the Company recognize the importance of achieving reductions to CO2 emissions across the entire vehicle life cycle. The Company believes that it is necessary to adopt a multi-solution approach toward this undertaking, in which it offers the most ideal option to match the needs of the energy sources, generation methods, and customers found in specific markets. These efforts are informed by a “well-to-wheel” perspective and a life cycle assessment perspective.

MAJOR INITIATIVES

- Declaration of goal of achieving carbon neutrality across entire supply chain by 2050

- Achievement of carbon neutrality at Mazda factories worldwide by 2035

- Mazda is advancing initiatives to accomplish these goals based on th following pillars with the cooperation of local governments and othe industries. Initiatives implemented in Japan are used as models for finding the best possible approach for initiatives at overseas factories.

1.Energy conservation

2.Shifting to renewable energies

3.Introducing carbon neutral fuels

- Reduction of CO2 emissions from factories and operating sites in Japan,* which account for approximately 75% of our global total CO2 emissions, by 69% from the level seen in FY March 2014 by FY March 2031, as a medium-term target and a step on the road map toward carbon neutrality

*Total of 17 factories and operating sites in Japan, including Mazda’s Head Office and Hiroshima Plant (Aki-gun and Hiroshima City, Hiroshima Prefecture), Hofu Plant (Hofu City, Yamaguchi Prefecture), and Miyoshi Plant (Miyoshi City, Hiroshima Prefecture)

WIDER USE OF CARBON NUETRAL FUELS

Key Initiatives 2:

ELECTRIFICATION

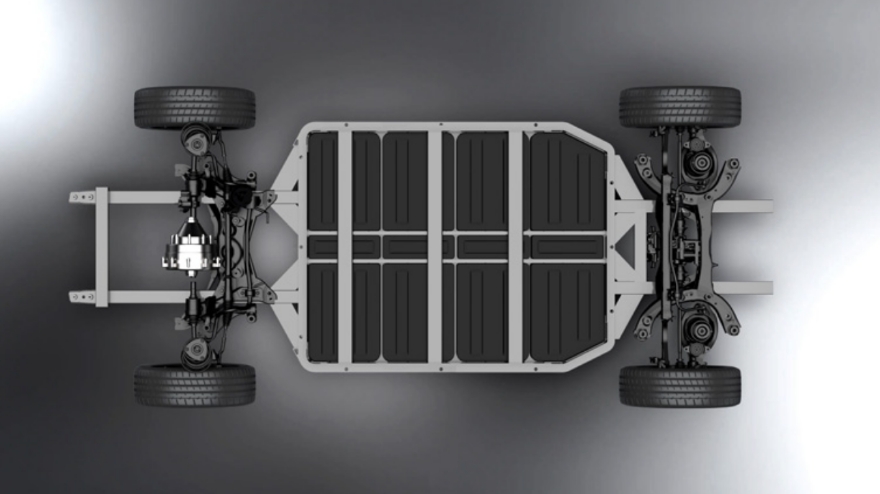

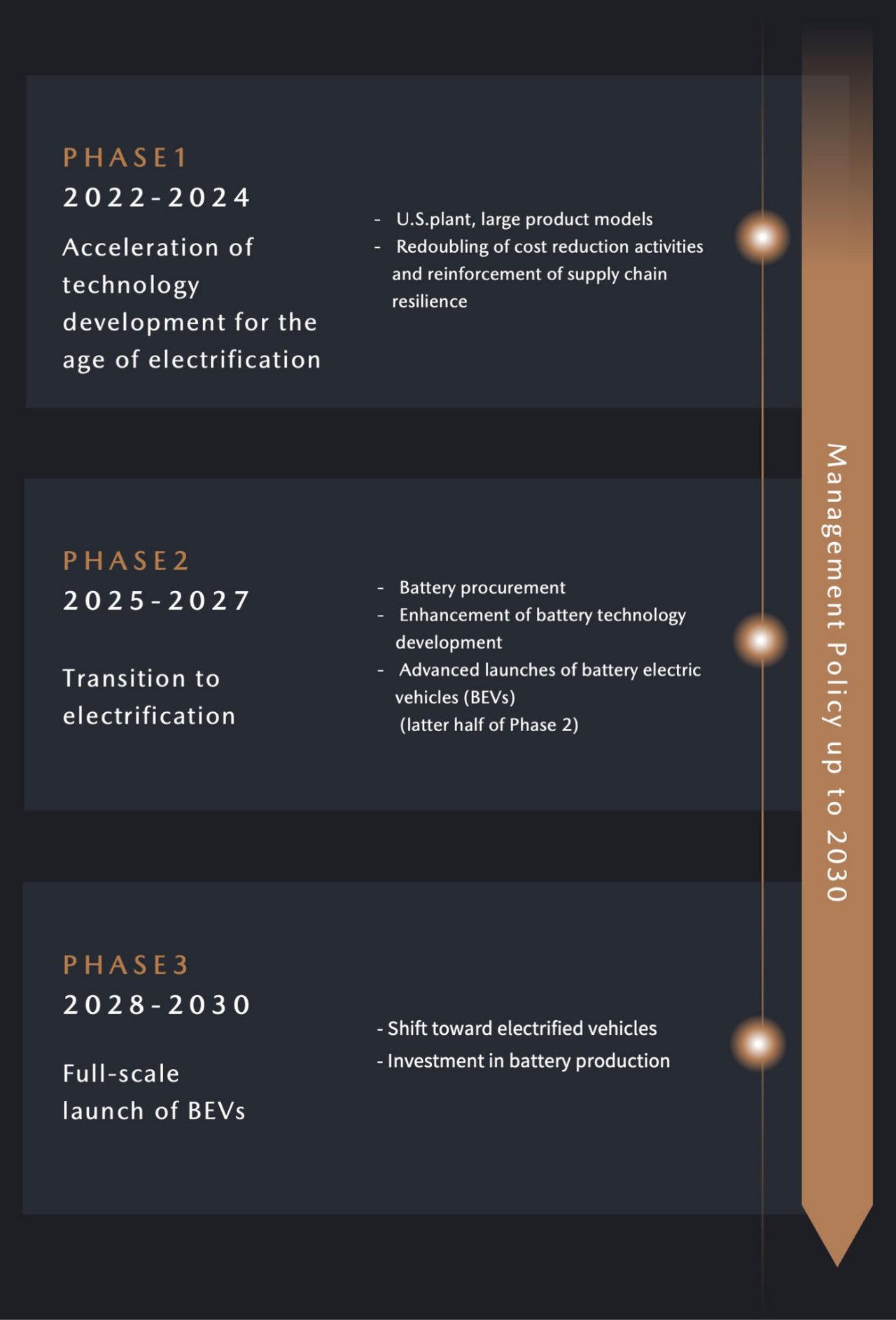

Mazda estimates that the BEV ratio of its global sales in 2030 will be between 25% and 40% given the trends in electrification policies and regulatory tightening seen in the relevant countries and regions. Mazda must be flexible and adapt to the coming changes, such as changes in regulations, consumer needs and acceptance levels, and infrastructure development. To this end, the Company will steadily work on the transition to electrification in three phases, proceeding with electrification step by step with the cooperation of its partner companies.

PHASE1(2022-2024)

PHASE2(2025-2027)

PHASE3(2028-2030)

Key Initiatives 3:

VALUE CREATION THROUGH CO-CREATION BETWEEN PEOPLE AND IT

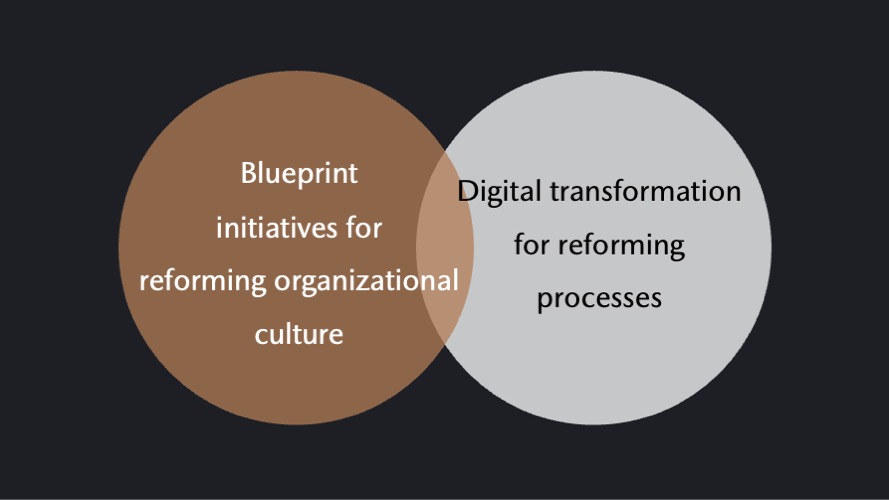

The source of Mazda’s ability to create value is its people. It is therefore crucial for Mazda to provide an environment in which employees feel compelled to tackle new challenges in order to maximize their skills and achieve our goal of doubled productivity.

The Company are approaching this undertaking by inspiring the leaders of divisions not directly connected with production to realize the role they play in such efforts and to diligently advance organizational culture and process reforms.

Key Initiatives 4:

COST REDUCTION AND SUPPLY CHAIN ENHANCEMENT

SUPPLY CHAINS

Mazda endeavors to implement improvements in each process, spanning from material procurement to product delivery to customers, and is also working to achieve overall process optimization by making the flow of goods as smooth as possible at the highest speed.

VALUE CHAINS

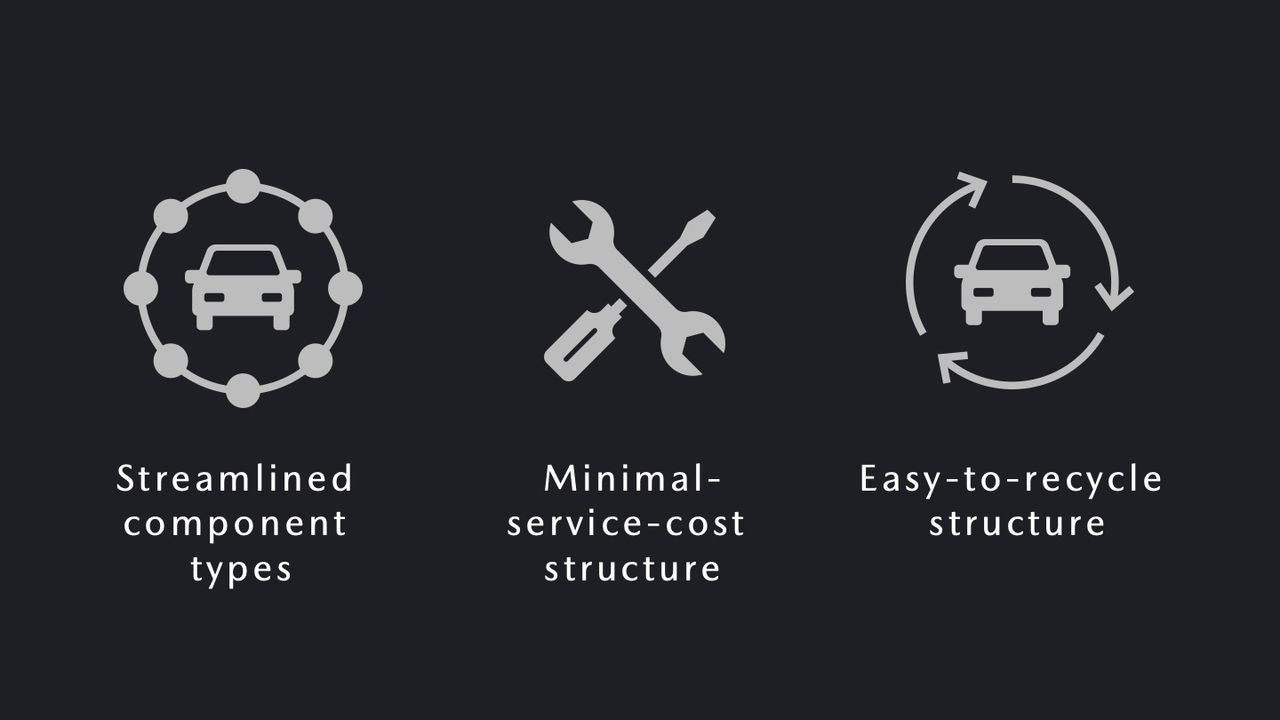

Mazda will redevelop processes so as to minimize fixed costs across the value chain and provide customers with the value they expect. This undertaking will involve efforts such as the optimization of product specifications and reduction of the number of different components at the planning stage and in pursuit of vehicle structures that are easier to recycle and require less in the way of after-service costs.

MAJOR INITIATIVES

SUPPLY CHAINS

Mazda seeks to minimize the impact of operating environment changes, such as geopolitical incidents and earthquakes and other large-scale disasters. The following initiatives are being taken to this end.

- Transformation of procurement system by reducing tiers in procurement of materials and parts and utilizing production locations for various parts that are closer to its production facilities

- Expanded use of more highly versatile materials and semiconductors

VALUE CHAINS

Mazda is combining its strengths with those of its suppliers to pursue maximum value for the customer through the following initiatives for building a more resilient value chain.

- Development of structure in which Mazda and suppliers can limit investment in development and equipment and improve equipment operation rates

- Limiting of administration, inventory, logistical costs, and other expenses related to customer services provided for marketed items

- Co-creative activities with parts and materials suppliers advanced based on a long-term perspective as part of normal operations