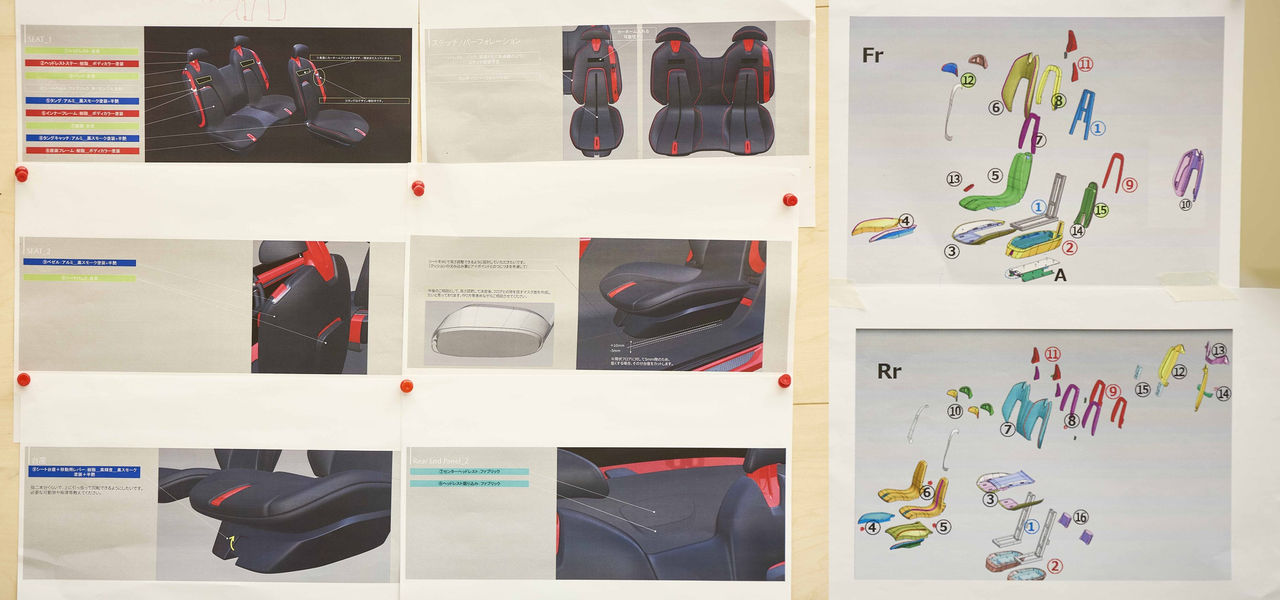

The center section of the seat was especially difficult. This area had different requirements from other parts, so we needed to find a completely new approach. Through repeated testing with the team, we realized we had to apply the fabric with uniform tension across the entire seat. Pulling it in sections would create wrinkles no matter what we did.

Before the actual attempt, the entire team practiced the application process as a test run. We confirmed the technique and discussed improvements. With that knowledge in hand, we finalized our procedure and then went for it.

We only had one chance. We couldn't afford to fail.

The pressure was constant, but we stayed in sync, calling out, reading each other's moves. Everyone knew instinctively what to do and adjusted on the fly. It came together because of the experience and trust we've built on the shop floor. True teamwork.