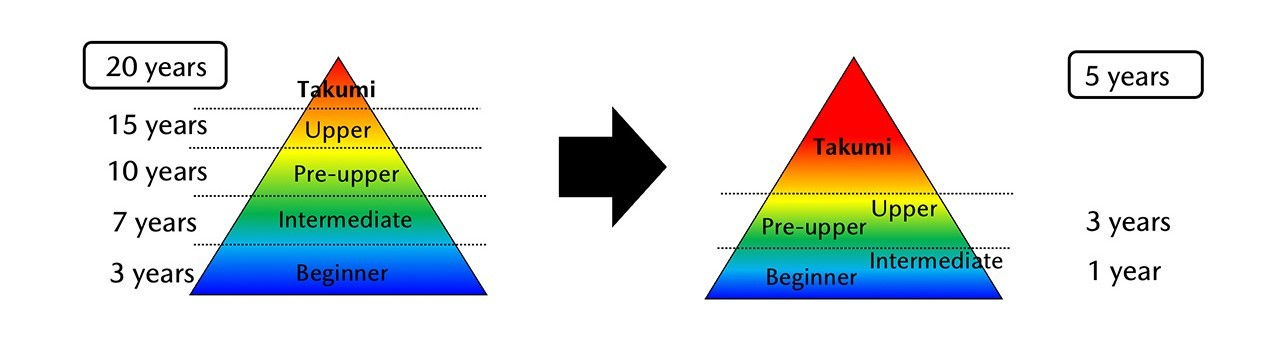

Japan's manufacturing industry has long been supported by skilled artisans and master craftspeople, known as Takumi. However, a declining birth rate, an aging population, and fewer people entering the trade means that these invaluable contributors are gradually disappearing from Japan's manufacturing sector, and traditional methods of passing down expertise are increasingly being challenged, including at Mazda.

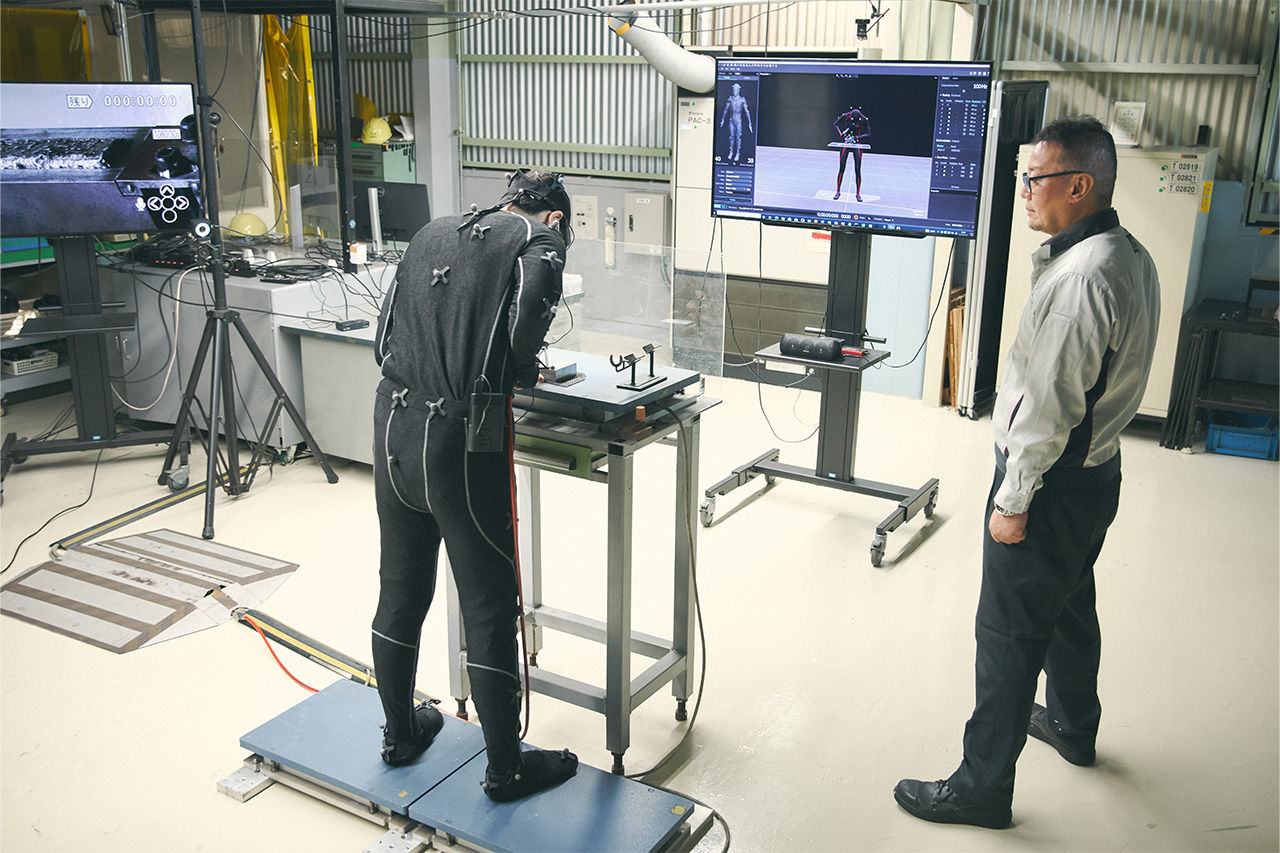

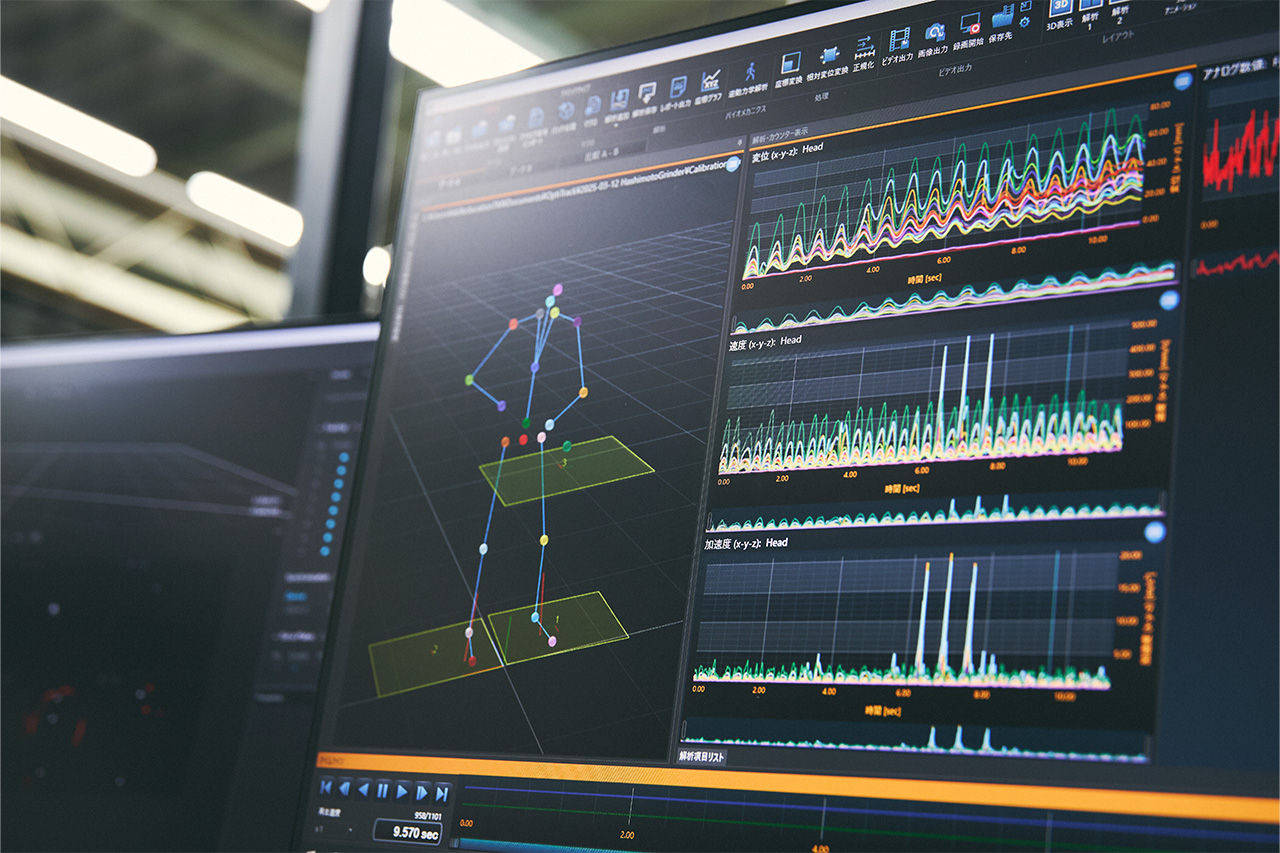

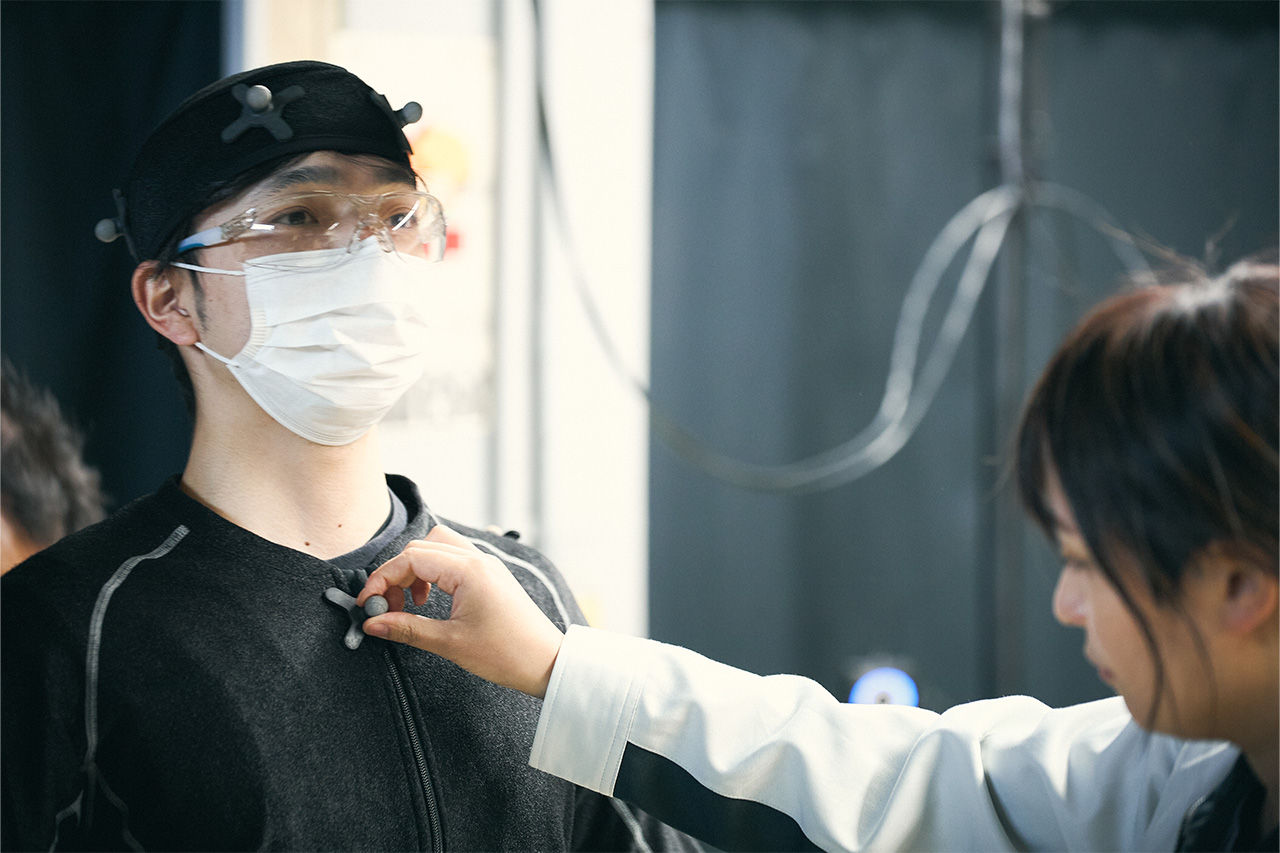

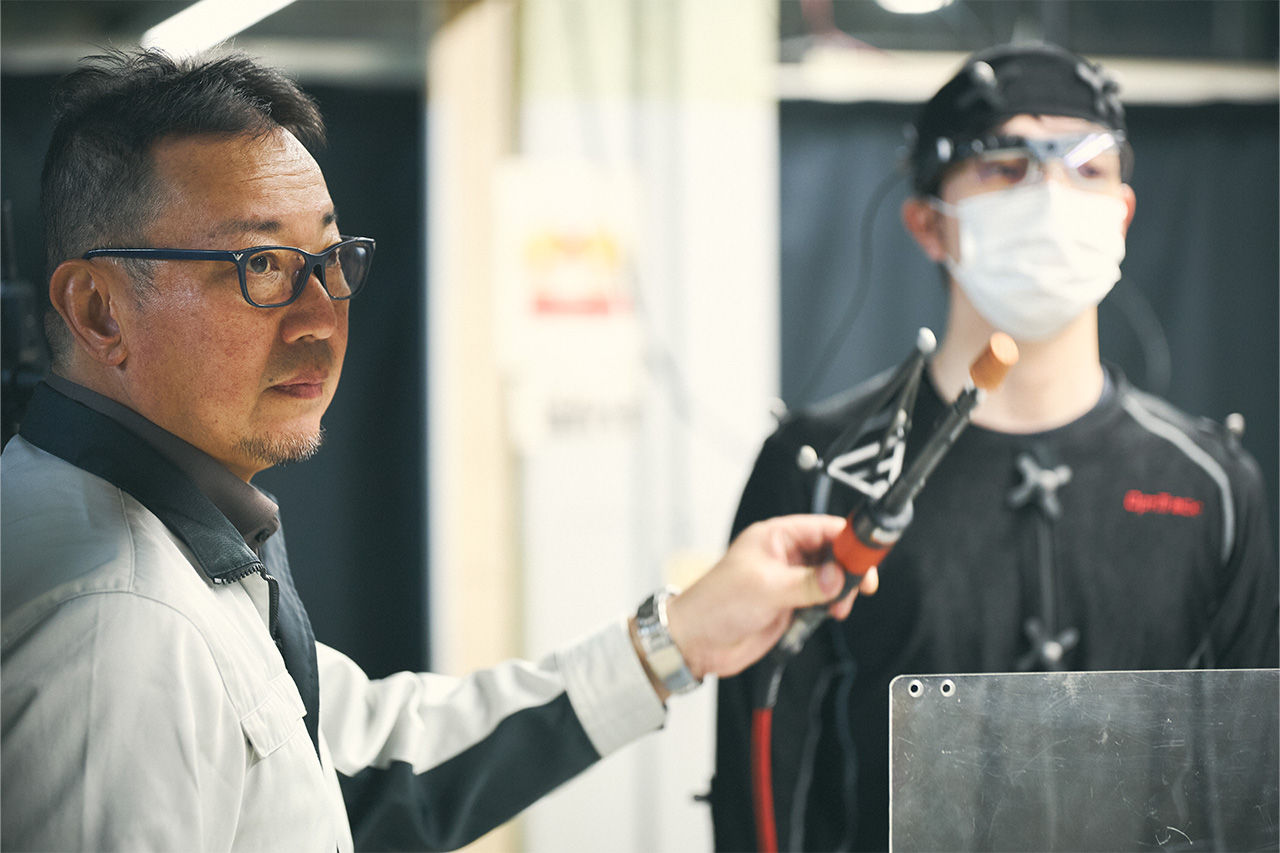

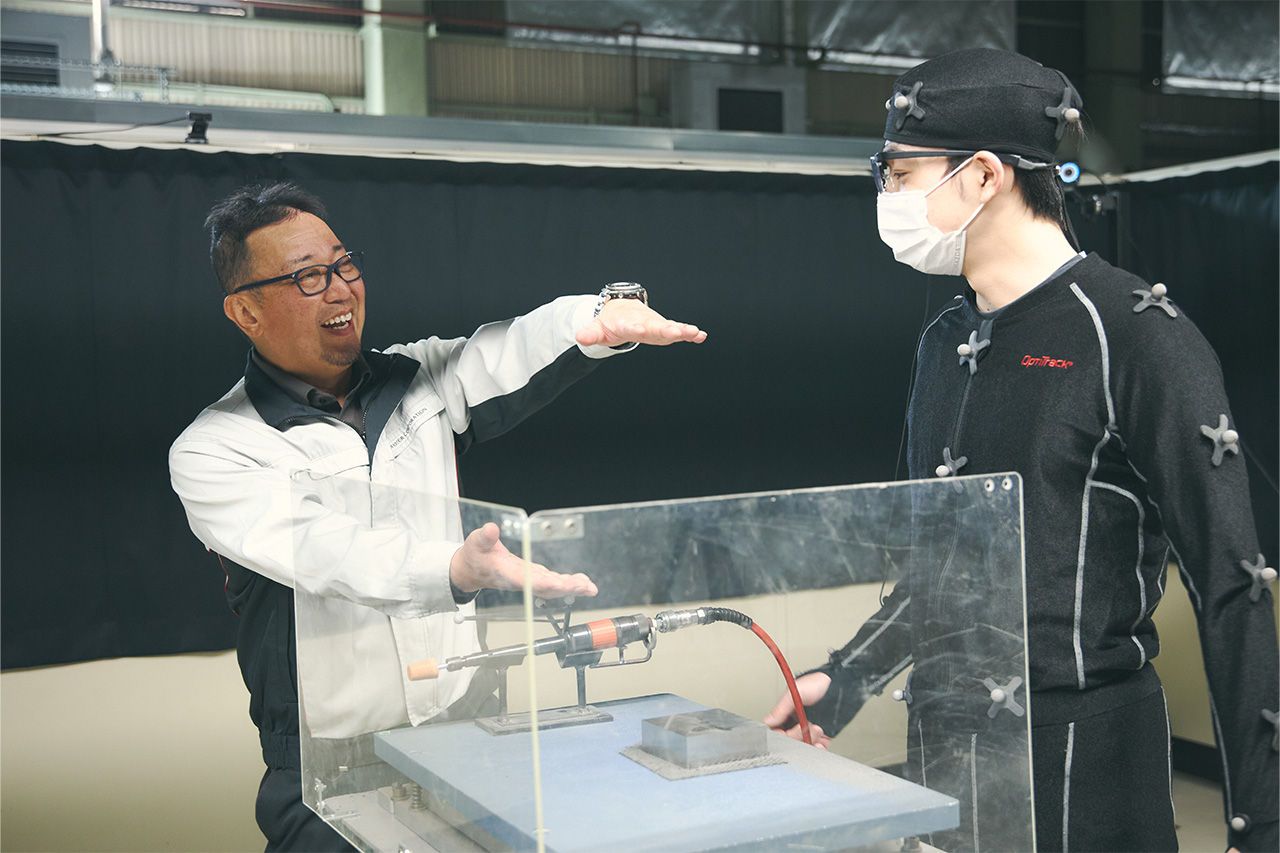

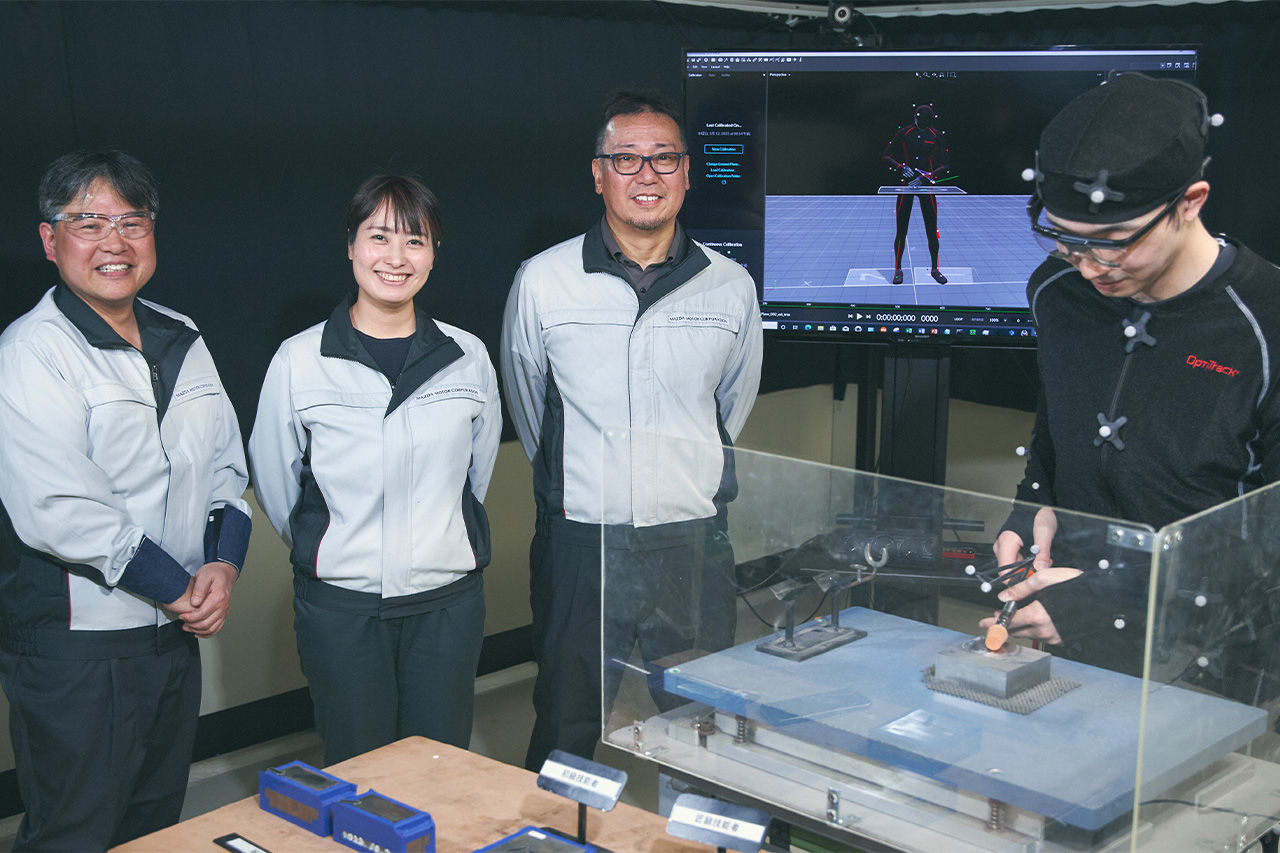

To address this, Mazda has adopted an unexpected solution: motion capture technology. This cutting-edge technology, traditionally used in film and gaming industries, is now being applied to visualize the movements of Takumi masters and apprentices, helping pass down Takumi skills in the workshop.

We interviewed two people leading this initiative: Chiharu Saeki, a technical engineer in the Tool & Die Production Department, and Minoru Suga, who leads training. We look at how they use motion capture in the workplace, and the technology’s role in passing on Takumi expertise to the next generation of craftspeople.