Following on from Episode 1, Mikako Aoyagi from the Communication Supervisory Group, Communication Supervisory Department is back as the interviewer for this article. Aoyagi joined Mazda in 2020 during the COVID pandemic, and partly influenced by a university friend’s social media posts on climate change, has developed a keen interest in environmental issues. Driven by her strong desire to “gain a clearer understanding of Mazda's environmental initiatives, current position, and challenges," Aoyagi interviews the Mazda employees who are implementing these measures in the field.

2025.05.12

Generating Clean Energy to Build Mazda’s First EV: How a Team Initiative Launched Mazda’s Solar Power Project - The Road to Carbon Neutrality Episode 3

Mazda has committed to making all its global factories carbon neutral by 2035, building its strategy on three key pillars: energy conservation, renewable energy, and carbon-neutral fuels.

To dig deeper into these initiatives, Mikako Aoyagi from the Communication Supervisory Group is exploring Mazda’s environmental initiatives through interviews with key personnel. In her previous interview, she examined how Life Cycle Assessment (LCA) is being integrated into business strategy to achieve carbon neural goals.

In this second installment, Aoyagi focuses on clean energy, interviewing members of the Plant Engineering Department who implement and manage the solar power generation facilities operating in Mazda's factories since 2021. She investigates the behind-the-scenes story of a project that began as a team initiative and uncovers the energy strategies needed to meet the challenging targets for achieving carbon neutrality.

- Clean EVs with Clean Power: A Project Born from Team Member Initiative

- Starting from Scratch: Trial and Error for Maximizing Generation Efficiency

- A New Challenge After Launch: How Team Collaboration Created an Anomaly Detection System

- CO₂ Reduction Equivalent to 430,000 Trees: Mazda’s Next Steps Toward Carbon Neutrality

Plant Engineering Department team members interviewed for this article: (from left) Kazuhiro Nakashima, Yusuke Nagata, and Ryota Taka.

Mikako Aoyagi. After joining Mazda in 2020, handled public relations for the compact SUV MX-30. Later, wanting to be more deeply involved in sustainability, moved to the Communication Supervisory Group. Today, she creates content for Mazda's sustainability website, which features the company's environmental, social, and governance (ESG) initiatives.

Clean EVs with Clean Power: A Project Born from Team Member Initiative

Aoyagi:

In my last interview on LCA(*) initiatives, I learned that solar panels were installed for the first time at the Hiroshima Plant in 2021. Could you tell me how this project came about?

*A method for evaluating environmental impact, such as CO₂ emissions, throughout a product's lifecycle, from production and transportation, to use and disposal.

Nagata:

Our Plant Engineering Department typically handles everything from planning and design to operation and management of all buildings at Mazda, including factories, cafeterias, and even fire stations. This project began in 2016 when development started on Mazda's first electric vehicle, the MX-30 EV Model, and we considered how our department could contribute to this initiative.

Yusuke Nagata

Nagata:

Electric vehicles don't emit CO₂ while operating. However, if the electricity powering these vehicles produces CO₂ during generation, then from a Well-to-Wheel perspective, we can’t truly call them carbon free.

We knew that if we made the electricity used to charge the EV batteries clean, we could deliver genuinely environmentally-friendly EVs to our customers. So, with that concept in mind, we submitted a team proposal for implementing renewable energy.

The MX-30 EV Model, Mazda's first mass-produced electric vehicle.

Starting from Scratch: Trial and Error for Maximizing Generation Efficiency

Aoyagi:

It’s amazing to think this began from a team project and not a company directive. But why solar power? Did you consider other renewable energy options?

Nagata:

We chose solar based on two considerations: lead time required until installation, and power generation capacity. Compared to other renewable energies like wind, geothermal, hydroelectric, and biomass, solar power has a shorter lead time and lower electricity unit cost. On top of that, the Setouchi region where Mazda's Hiroshima Plant is located has one of the highest amounts of solar radiation in Japan. From a power generation perspective, it made sense to first consider solar power.

View of Hiroshima Bay from the Hiroshima Plant (Head Office)

Aoyagi:

But Mazda had never worked with solar panels before, right? You must have faced challenges as you got familiar with this new technology?

Nagata:

Yes, we did. Solar panels were equipment we had no experience with, so initial trials were very challenging.

In particular, we struggled selecting the panel materials. Panel materials come in various types with different characteristics. We weren’t willing to simply go off the data in the catalog. Instead, we installed different panels around the company and conducted our own evaluations from multiple perspectives, including power generation, aging deterioration, and temperature characteristics. We took two years to select the material.

The solar panels installed at Mazda’s Hiroshima Plant.

Nagata:

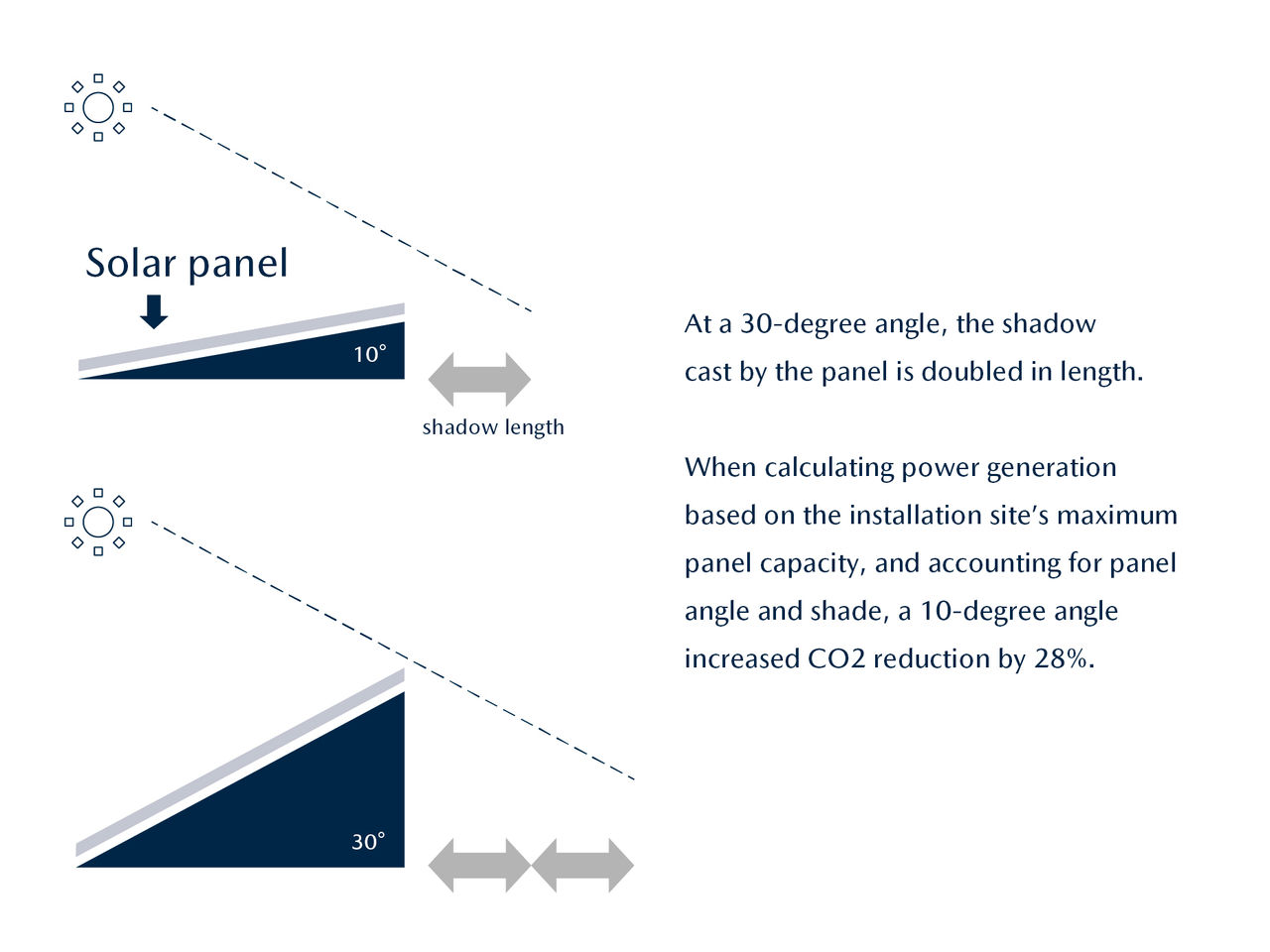

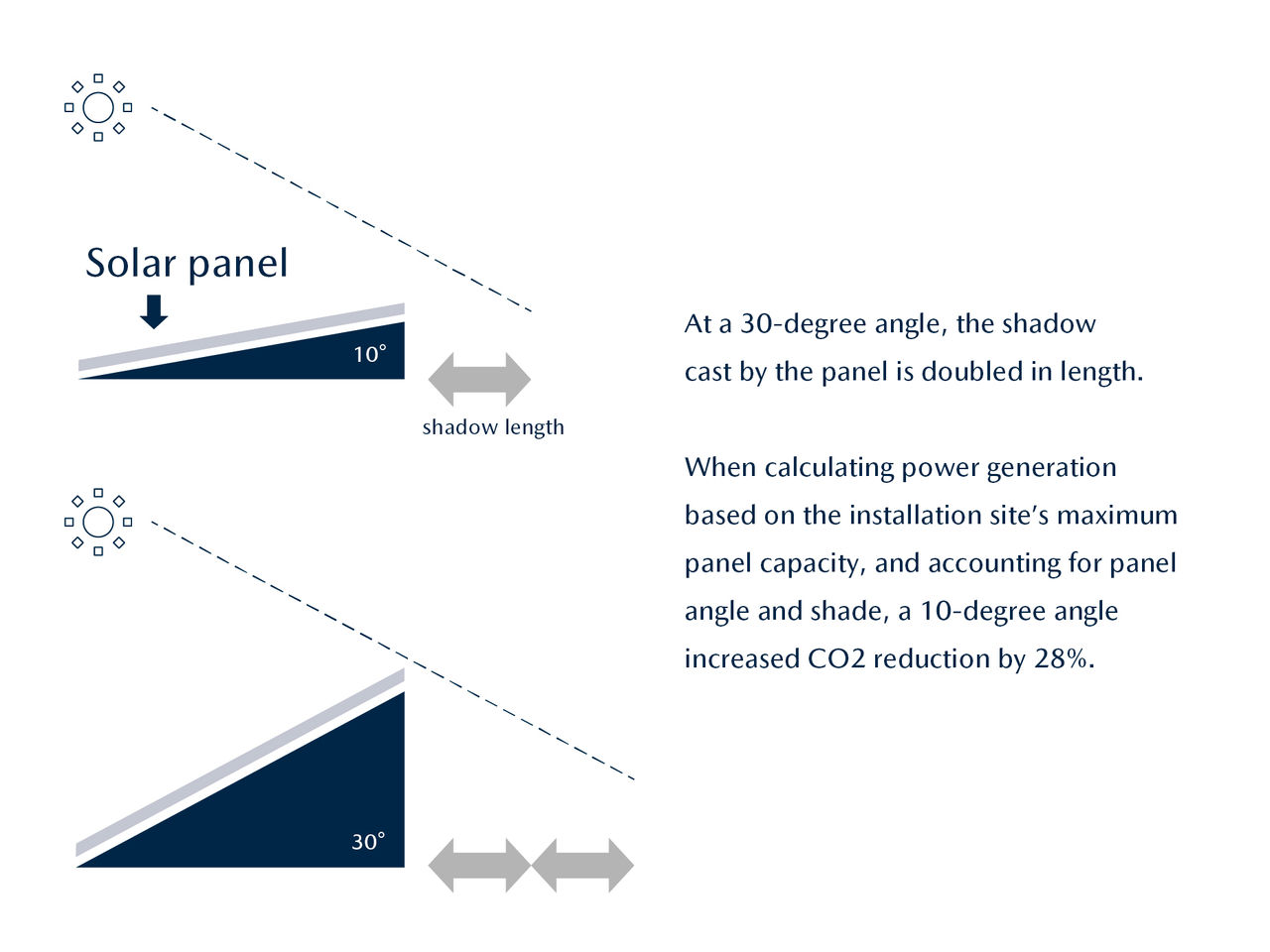

We also went through a rigorous process of trial and error when deciding how to position the panels to maximize power generation efficiency. Generally, it's considered most efficient to fix panels facing south to receive sunlight from sunrise to sunset, at a 30-degree angle that accounts for seasonal changes in the sun's height. However, this is only the optimal solution when considering a single panel.

For example, installing panels at a 30-degree angle creates shadows behind the panels. The greater the angle, the longer the shadow, so when installing multiple panels, the rows must be spaced widely to prevent power generation from decreasing due to partial shading.

A south-facing 10-degree angle (shown above) was adopted to provide the highest power generation efficiency for the panel installation site.

Nagata:

To secure as much power generation as possible across the entire site, we needed to determine the installation angle considering all requirements including panel installation spacing, changes in the sun's altitude, the length of panel shadows, and the size of the installation site. After various simulations, we landed on a south-facing 10-degree angle as the one which would provide the highest power generation efficiency for this panel installation site.

Aoyagi:

What's the total size and capacity of the installed solar panels?

Nagata:

We installed about 2,700 solar panels on the 11,000 square meter rooftop of the building at the Hiroshima Plant, generating about 1,500 megawatt-hours of electricity annually. This is equivalent to the annual electricity usage of about 350 households. Or, if we compare it to the power needed to light a Hiroshima Toyo Carp’s night game at Mazda Zoom-Zoom Stadium Hiroshima, we generate in one year at the plant what would be used over about 11 years at an average rate of 50 games per year at the stadium.

Nagata:

There was another reason we chose this specific location for Mazda's first solar panel installation. The battery charging facilities for the MX-30 EV Model were scheduled to be introduced on the floor below this building.

By sending the generated electricity directly to the battery charging facilities below, we minimized electricity loss. We also charge batteries for the plug-in hybrid model MX-30 e-SKYACTIV R-EV here.

Aoyagi:

Is all the power generated by solar power used for the battery charging of the MX-30 EV model and plug-in hybrid model?

Nagata:

Actually, the electricity used for assembly and battery charging of MX-30 EV model and plug-in hybrid model accounts for only about 20% of the generated power. The remaining 80% is used in other car manufacturing processes at the plant.

A New Challenge After Launch: How Team Collaboration Created an Anomaly Detection System

Aoyagi:

After installation, did operations advance smoothly?

Nagata:

Not exactly! To maintain stable power, you need to constantly monitor the condition of the solar panels, but it's difficult for people to visually inspect about 2,700 panels. We asked the operations team to consider different methods, and the first idea proposed by Nakashima was drones.

Nakashima:

The Plant Engineering Department had already been experimenting with drones for high-altitude inspections, so we programmed predetermined filming routes and took two types of footage along the rows of solar panels: standard and infrared.

But, we soon realized it would take an immense amount of time to identify abnormalities from the photos and video data by hand, and knew we had to explore alternative approaches.

Kazuhiro Nakashima

Taka:

We considered whether we could create a system that detects abnormalities from power generation data and narrows down panels with malfunctions. However, since solar power generation varies greatly depending on weather conditions, it's difficult to determine abnormalities from power generation data with the human eye.

Ryota Taka

Taka:

We tried different approaches to make this automatically detectable, but without precedents, we struggled to find a solution. Then, from conversations with Nakashima and other team members, I suddenly landed on the idea of using AI.

Nakashima:

Taka immediately began investigating, and to everyone’s surprise, completed the system just a month later.

Aoyagi:

Did you develop the AI yourself, Taka?

Taka:

Yes, I did. Which is funny because I had zero programming experience! But I started studying on my own and gradually developed the AI software. I searched for code examples online and used generative AI tools to create code, figuring things out step by step until I somehow managed to complete it (laughs).

Aoyagi:

Creating a system in one month while learning from scratch is impressive!

Taka:

I saw how this issue was burdening our staff and I wanted us to produce sufficient clean power as soon as possible.

Nakashima:

Taka and many of the younger team members are eager to try new technologies. I'm often surprised when I discover what they've accomplished after they’ve completed it..

Taka:

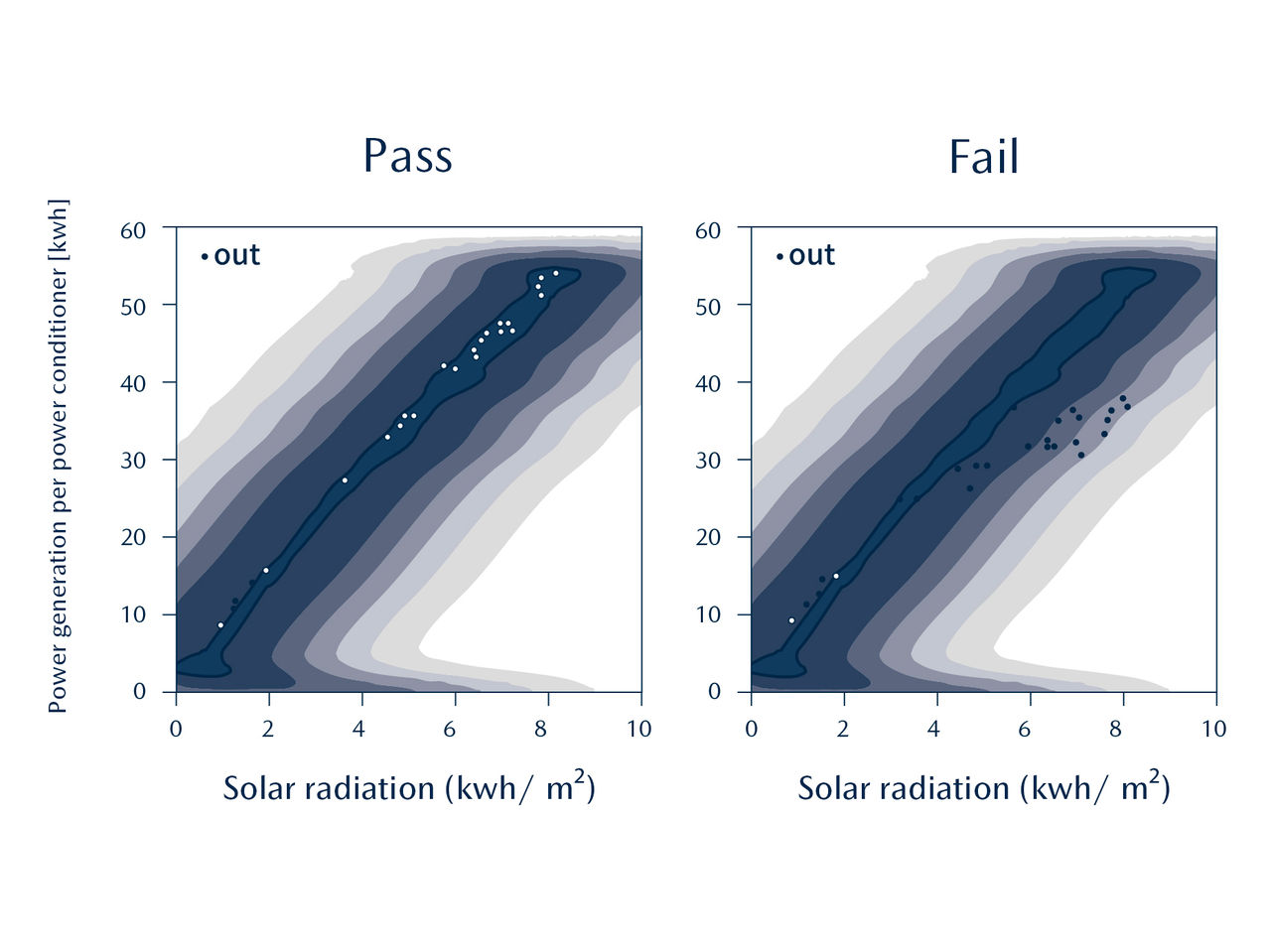

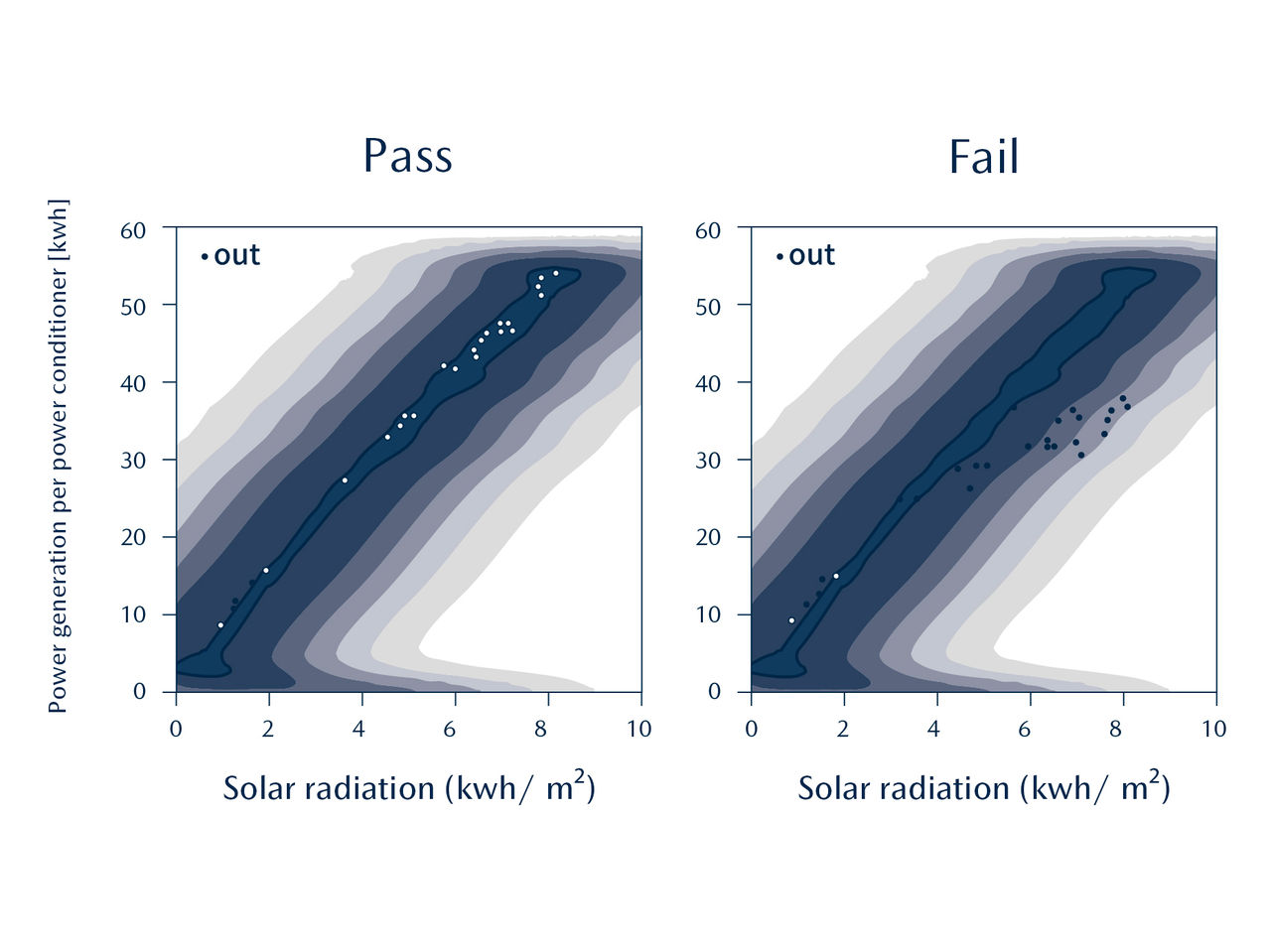

This here is the anomaly detection graph. If the power generation data falls within the middle range, it passes. There's a device called a power conditioner that collects direct current generated by multiple solar panels and converts it to alternating current. We extract power generation data for each power conditioner to detect abnormalities.

The x-axis represents solar radiation, and the y-axis represents power generation, with each point showing the power generation of one power conditioner. Power generation should increase with increased solar radiation, but if the rate of increase is lower than normal, some abnormality is suspected.

Taka:

About a year has passed since we began operating this system, and we've been able to detect several abnormalities, including power conditioner part failures and snow accumulation on panels, leading to prompt responses. As we continue to teach the AI with normal power generation data, detection accuracy is also improving.

CO₂ Reduction Equivalent to 430,000 Trees: Mazda’s Next Steps Toward Carbon Neutrality

Aoyagi:

What results have you achieved by introducing solar panels?

Nagata:

From August 2021 to March 2025, our measurements confirm that Mazda's solar power generation facilities have contributed to a CO₂ reduction equivalent to what about 430,000 cedar trees would absorb.

However, our goal at Mazda is to achieve carbon neutrality at all factories, including those overseas, by 2035. Rather than relying solely on in-house solar power facilities, we're advancing the use of a mechanism called corporate offsite PPA to procure electricity derived from renewable energy at external sources.

This corporate offsite PPA allows businesses involved in electricity supply and demand to collaborate on and contribute to carbon neutral goals and sustainable economic growth in the Chugoku region. Mazda partners with electricity power producers to develop new renewable energy generation facilities and commits to purchasing that electricity long-term. In this way, we're working to reduce CO₂ emissions together with the local community.

Taka:

In 2023, Mazda, Toyo Seat, Choshu Industry, and Chugoku Electric Power formed a four-company collaborative offsite corporate PPA. Currently, this initiative involves just four companies, but Mazda are reaching out to other suppliers and regional companies from different industries to expand the collaboration.

Offsite corporate PPA framework.

Aoyagi:

Finally, what are your goals for the future and what would you like to work on next?

Nagata:

Moving forward, we need to focus on cost reduction and effectively introducing renewable energy. Within Mazda, we're already conducting trials and experiments with different renewable energy sources, not just solar power. We want to explore possibilities suited to each characteristic, cooperate with the region, and achieve CO₂ reduction while strengthening the regional economy.

Taka:

In the current solar panel anomaly detection system, we still need human intervention when inspecting the abnormalities. I want to make this process more efficient. In the future, for example, I envision a system where AI can narrow down the area of abnormality and drones automatically capture those locations and generate reports. Through initiatives like the corporate offsite PPA, I’m hoping to incorporate techniques from electricity power producers to create better systems.

Nakashima:

I want to support our early-career colleagues so they find purpose and enjoyment in their work. As our solar panel project shows, insights often emerge when you change your perspective, even as you tackle your daily tasks. I see my role as helping team members discover the excitement that comes with developing their work in meaningful ways.

From the Editorial Team

Aoyagi had this to share about her experience.

“As someone early in my career, I found it inspiring to learn how this project was proposed and implemented through trial and error by early-career team members like myself. I was also surprised to discover that everything from selecting solar panel materials to installation and developing the inspection system was handled entirely in-house.

The solar power generation facilities created through collaboration among Plant Engineering Department members embodies Mazda’s integrated manufacturing approach. And their plan to use the corporate offsite PPA mechanism to partner with the broader region on solar installations and renewable energy promotion reflects Mazda’s deep connection to the community it has grown alongside. I can't help but feel excited about where these initiatives will lead.

In the next and final interview, I'll be exploring the corporate offsite PPA and its future potential.”