Mazda’s culture of innovation, the same spirit that led to the mass production of the rotary engine, continues to create breakthroughs led by unique vision, beliefs, and technical capabilities. In 2010, the SKYACTIV engine (SKYACTIV-G) that debuted in the Demio(Mazda2) was another embodiment of Mazda's technical prowess. The engine achieved hybrid-level fuel efficiency of 30 km/liter (10-15 mode) using only internal combustion, without relying on motor assistance. It was a groundbreaking innovation that sent shockwaves through the car industry.

As the rest of the industry accelerates toward electrification, Mazda has continued to develop this technology, bolstered by the conviction that even if motors eventually handle part of the power, efficient internal combustion engines will always be an essential factor in addressing environmental concerns.

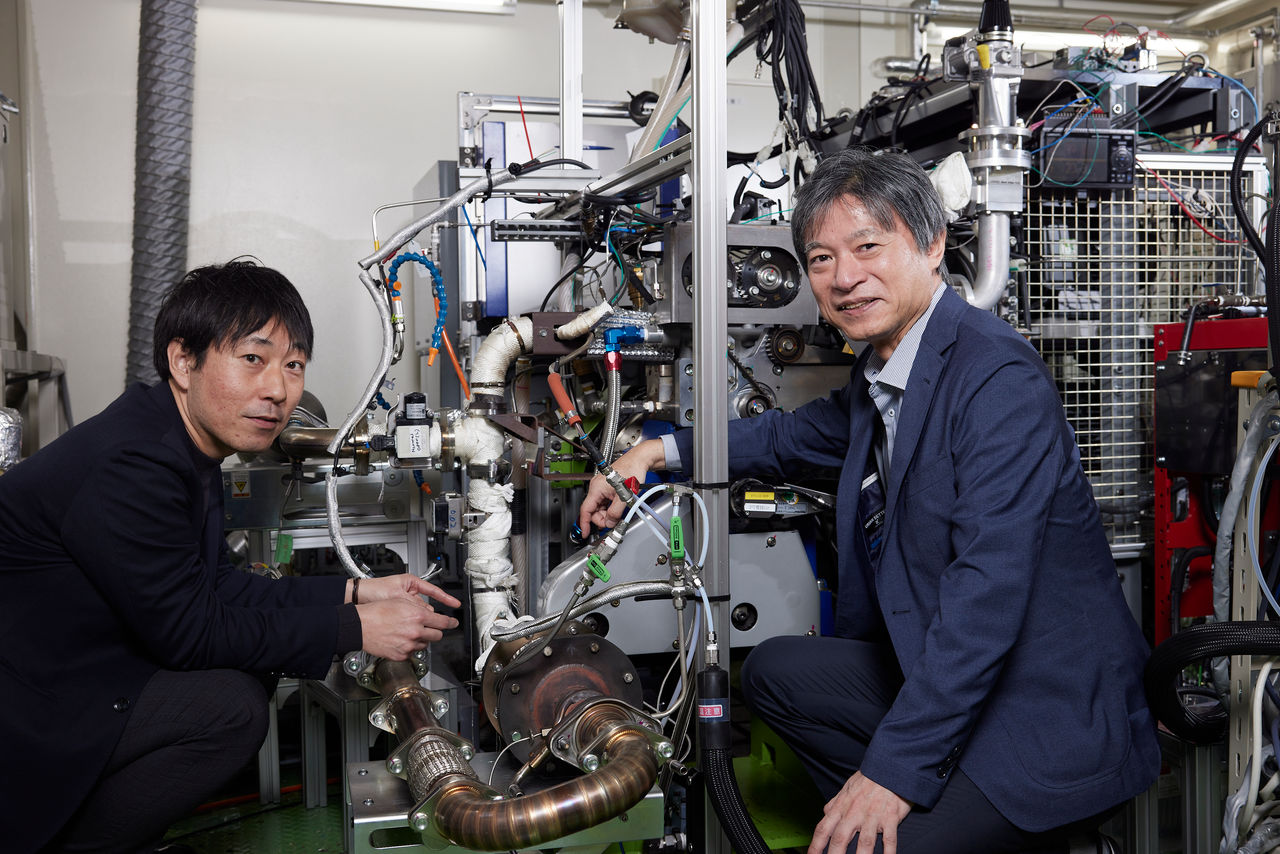

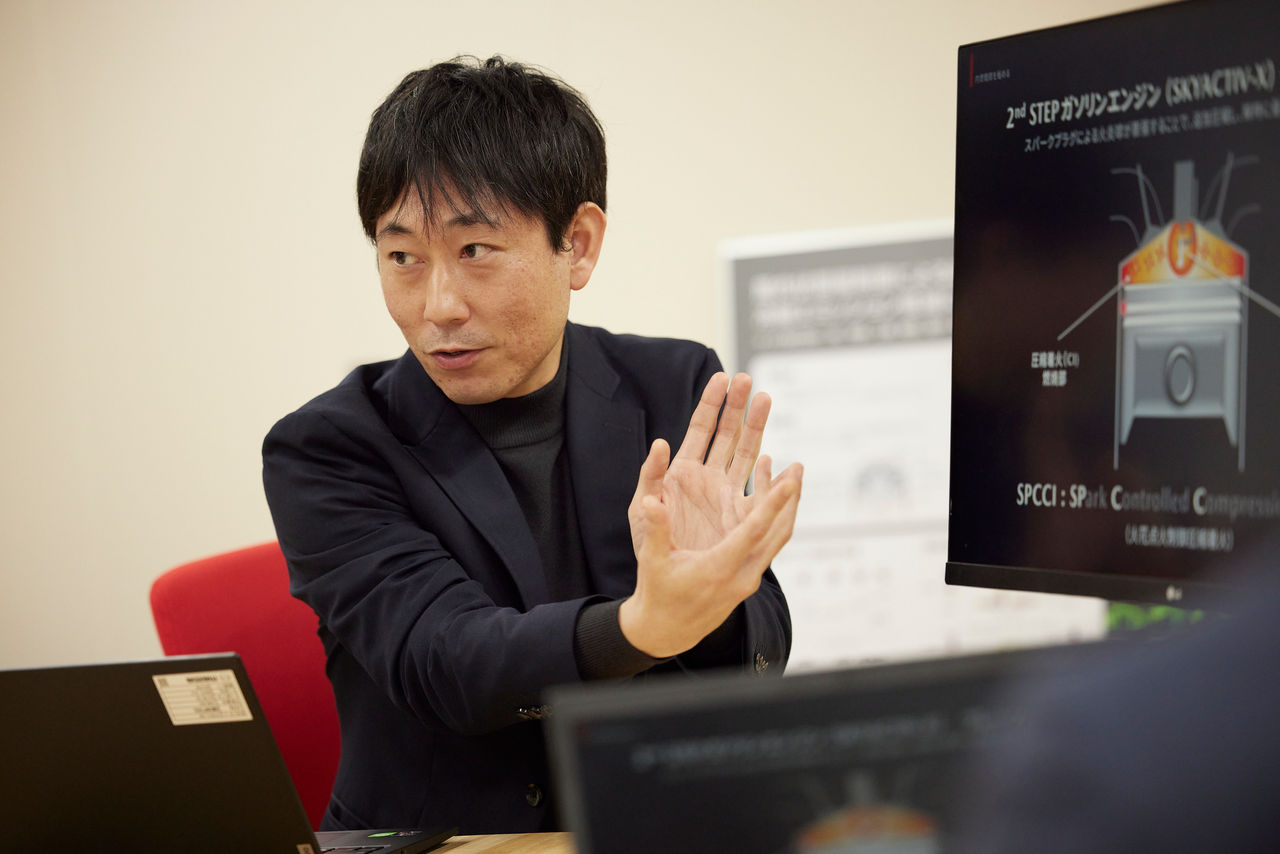

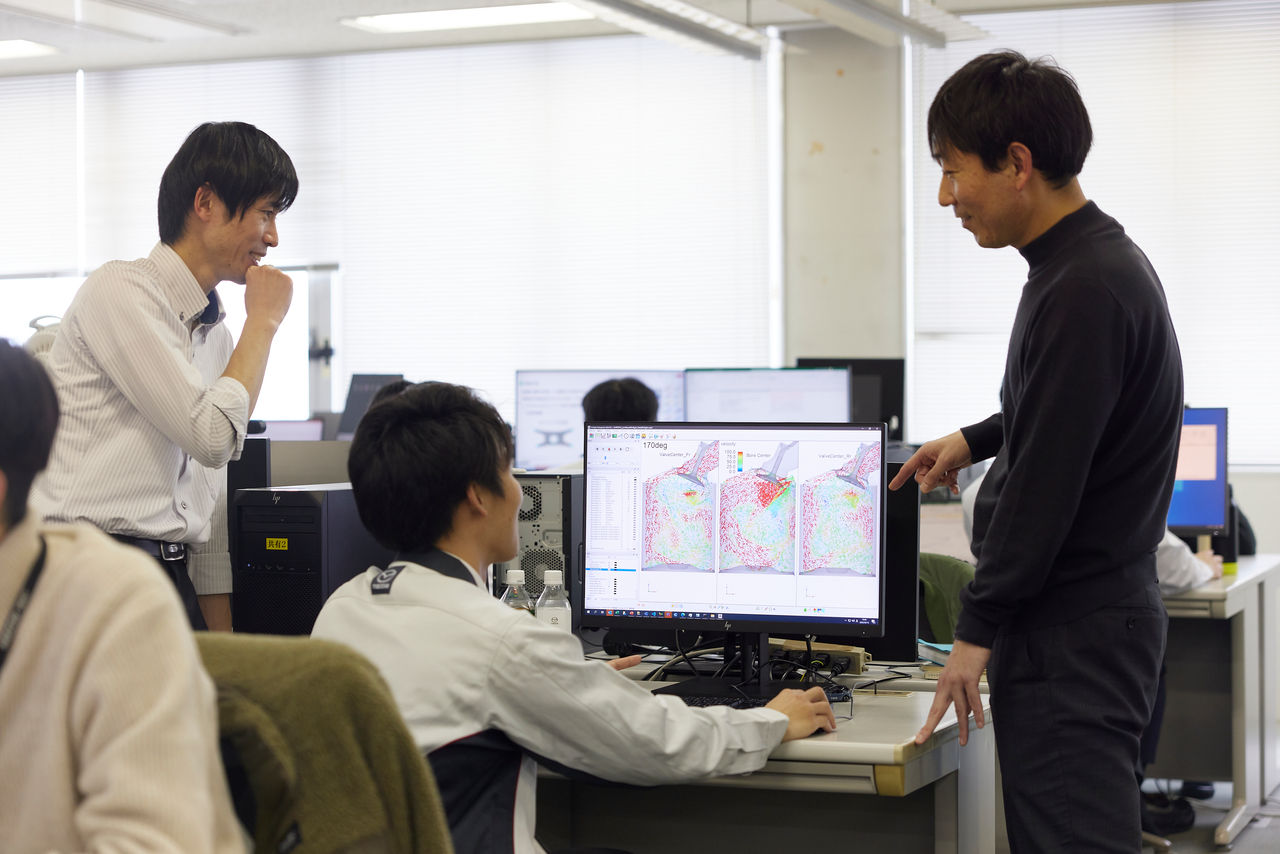

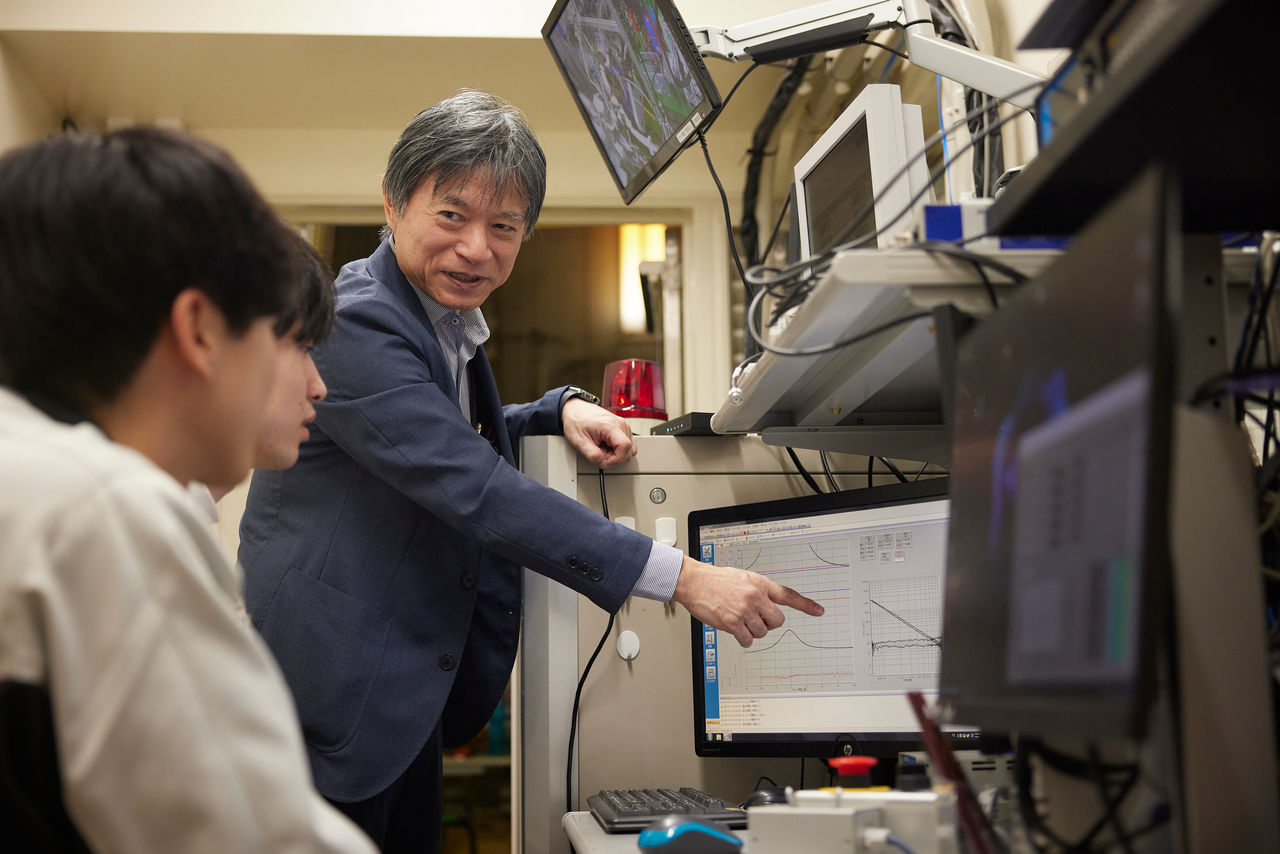

In conversation with two key figures from Mazda's internal combustion engine development, Masahisa Yamakawa from the Technical Research Center and Michiharu Kawano from the MBD(Model base development) Innovation Department, we'll explore the evolution of SKYACTIV engines, the role of internal combustion engines in the age of electrification, and the future potential of internal combustion engines as carbon-negative technology.