In Pursuit of Alluring Retraction

The People Behind the MX-5: Kouichi Matsumoto, Roof System Engineer

The People Behind the MX-5 series features interviews with engineers and designers involved in the development of the fourth-generation model. This second episode in the new series focusing on the MX-5 RF hardtop introduces Kouichi Matsumoto, who led development of the retractable roof. Read on to find out about the long process of trial and error that finally led the team to a solution no one expected.

Early days of development: quietly determined, but with no solution in sight

Kouichi Matsumoto, leader of the team that developed the MX-5 RF’s retractable roof, leans over a mock-up on his desk and carefully moves each part. “The roof separates into three sections like this,” he says. “The rear window’s movement is quite complicated.” Matsumoto smoothly stows the roof and returns the rear roof to its original position, where it joins neatly with the body to create a characteristic fastback style. “That’s how it works,” he says, looking up.

Kouichi Matsumoto

The soft-spoken Matsumoto answers our questions about the development of the new roof, whose complicated and beautiful movements would inspire curiosity in anyone.

“When development of the new MX-5 began, the aim was to get the soft-top just right,” he says. “From the beginning, the plan was to develop a hardtop, but we didn’t originally intend to incorporate the features of both models. Nobody was thinking about how to stow the hardtop. As development proceeded, I started to worry about how the hardtop would work out. That was early 2013.”

What Matsumoto was worried about was space. It was obvious that trying to fit the rigid hardtop into a space just big enough for the folding cloth-top would be like trying to pour a large jug of water into a smaller jug. It simply wasn’t going to fit.

“Development went through several stages. At first, we wondered if we could use a mechanism like the one on the third-generation MX-5. The model is 10 years old, but it’s still competitive in terms of how quickly and smoothly the roof opens and closes. We looked at various options, like using the same basic mechanism but pulling the rear of the roof back and using the space that would be created underneath. We also looked into making the deck cover bigger, and even considered dividing the roof into seven parts.

But everything we tried was ugly. And if you divide the roof into many sections, it sticks up when folded making the car look like it’s carrying a load on its back. So, we were at a loss.”

Repeated trials lead to a solution: fastback styling

As Matsumoto continued investigating different stowage methods, it became increasing clear that it would be physically impossible to stow the entire roof.

“It seemed as if all that testing was fruitless, but in fact that steady effort was necessary to find the real solution,” he says. “Because we examined each idea thoroughly, we were able to discuss the possibilities among all the members of the development team, regardless of their department. That opened up new avenues.”

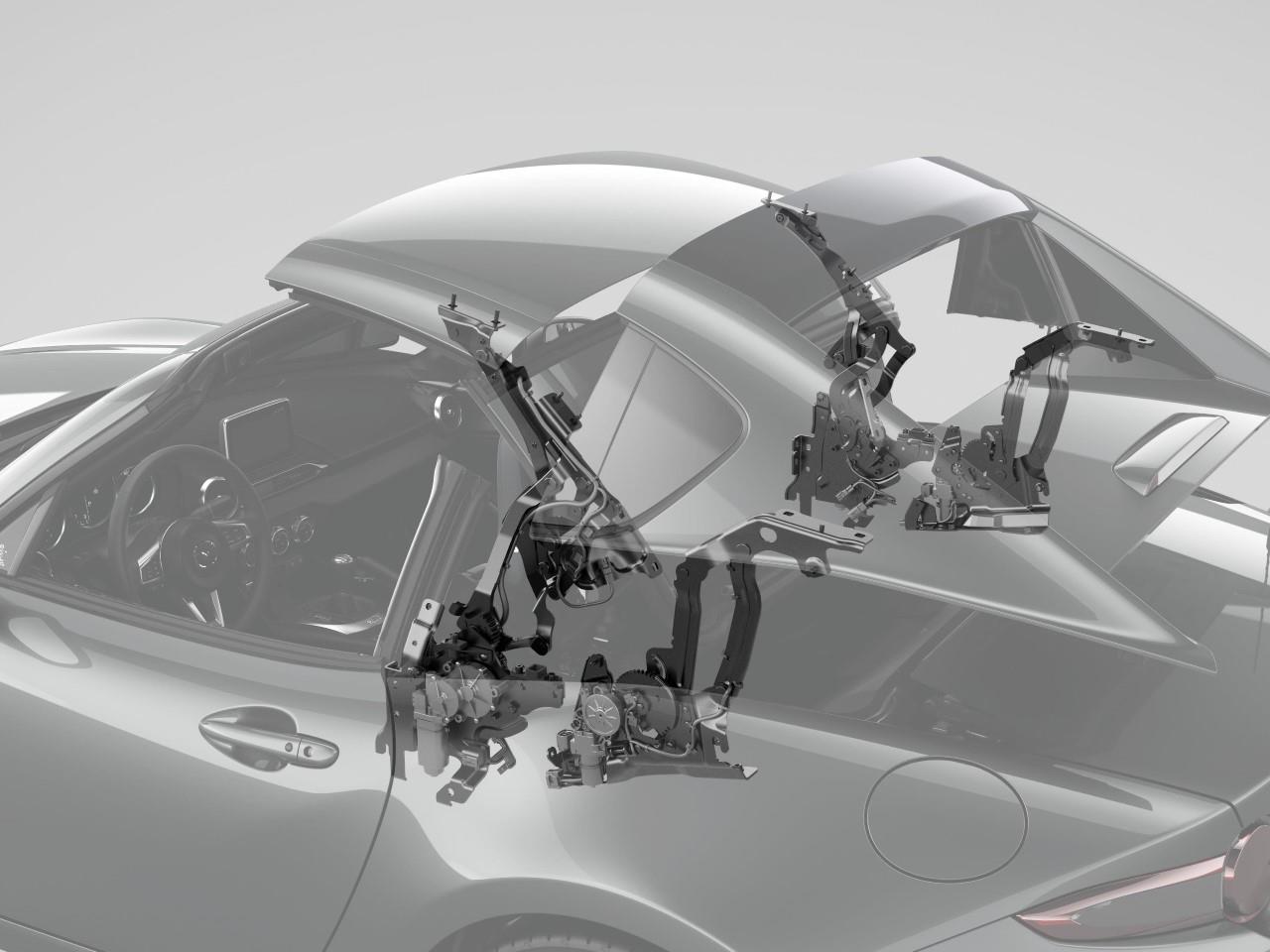

This image shows the internal workings of the roof mechanism.

Matsumoto presented his results to the MX-5 team just before development of the hardtop got into full swing. He soon convinced everyone that, under the current assumptions, it wasn’t possible to stow the whole roof and still have a good-looking car.

“After my presentation Minamisawa-san, who was in charge of exterior design, showed us a sketch of a rigid hardtop as a fastback that he’d drawn while I was talking. As a matter of fact, a few days before that, Nakayama-san, the chief designer, had stopped by to ask me whether the rest of the roof could be stowed if we made the car a fastback and left the rear roof in place. I told him it should be doable but hadn’t given it any more thought. When I saw Minamisawa-san’s sketch, I recalled that conversation and everything just fell into place.”

Matsumoto’s task thus far had been to prove that what the team was trying to do was impossible. If he hadn’t been so convincing, they might never have arrived at the solution of adopting a fastback design. They had to explore every possibility to finally come up with the MX-5 RF they were after. And as development moved forward, another of Matsumoto’s talents, his creativity, came into play.

Exploring the possibilities of design through co-creation

“Everyone agreed that this was the way to go, so there was no going back now. And there were a lot of issues to tackle: How wide should each section of the roof be? What kind of linkages should be used to support each part to facilitate stowage? How should each part move? The linkages on the old model weren’t rigid enough to support the new roof, so they had to be redesigned.

“When considering the linkage structure, we first design it on the computer to ensure that it meets our basic requirements and won’t be in the way of passengers in the car. Once we’ve made sure that they move smoothly, we test the rigidity of the linkages. If one is not rigid enough, it must be redesigned. When the shape of one part is changed, many other parts have to be changed as well. We repeated this process over and over again.

“This is a highly specialized technology, and the suppliers we worked with were really dedicated. I was sometimes surprised at the lengths they would go to meet or exceed our requests, which went beyond usual development. But they understood what we were aiming for with the MX-5 RF, and worked on its development with great enthusiasm.”

MX-5 RF’s roof: a quiet yet dynamic mechanism enables beautiful motion

One day, when Matsumoto was repeatedly changing the layout by mere tenths of a millimeter, Minamisawa came to his office and asked him to move part of the mechanism 70 millimeters further inside for the sake of the design. Matsumoto was shocked.

“I told him it couldn’t be done. He said he figured as much, and then said he had something he wanted to show me. He took me to the design studio and then started sticking narrow black tape used to try out different designs onto a clay model of the MX-5 RF. ‘Take a look at this line,’ he said. ‘Now look at this one. This one looks better, right?’ I couldn’t help laughing as I agreed. So, I had to throw everything out and start over. And it wasn’t just design. I got the mechanism right only after having similar conversations with members of many other teams, including production.”

The faint lower line was dictated by the mechanism layout; black tape marks the line Design originally hoped to achieve.

The line on the finished product is even closer to perfection than Design’s original line.

At the end of our interview, Matsumoto, who has spoken quietly and matter-of-factly throughout, stands up and says, “If I’d just rejected the designers’ request out of hand, they might have given up. But I’m not that type of person. I knew how serious they were about this car, and how determined they were to find that perfect line. Both personally and as an engineer, I couldn’t allow myself to ruin their design without giving it my best shot as the person in charge of layout.”

Underneath the beautiful roof of the MX-5 RF is a mechanism that is both quiet and powerful, not unlike Matsumoto himself. When you witness its exquisite motion, spare a thought for the soft-spoken engineer who was behind it.

Check the following links for more interviews and behind-the-scenes stories from the development of the MX-5.

- - The Power of Co-Creation Brings New Value to the MX-5

- http://www.mazda.com/en/notification/20160831/

-

-

- - MX-5 RF Stories: In pursuit of a simple dream – MX-5 smiles for all

-

- - The People Behind the MX-5

- http://www2.mazda.com/en/stories/craftmanship/mx-5/mx-5_25th/interview/yamamoto.html