Metal Mold Maintenance

- Control on a 1/1000-millimetre Level Brings KODO Design Alive

For Mazda, a car is not just a huge chunk of metal; a car has a life of its own. That’s why Mazda is committed to making cars with varieties of expressions and strong vitality, both of which are signs of life. This concept is translated to a design language called “KODO Design” which is revolutionizing car design in the 21st century.

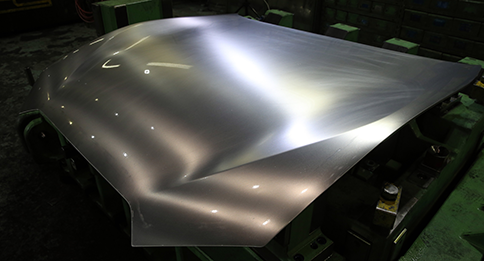

KODO Design is realized by many parts which are an accurate reproduction of designer’s drawings thanks to metal stamping based on intricate calculations. The quality of metal stamping depends on the precision of “metal molds”, which directly affects beauty and the quality of car’s body. In other words, designers are a heart of KODO Design while metal molds form a backbone.

Metal molds are used to make parts such as hood. To maintain the metal molds and restore them on a 1/1000-millimetre level, which is critical to reproducing the full beauty and glory of KODO Design visualized by designers, is a job of skilled “Press Mold Maintenance” experts. They are the guardian angel of KODO Design that breathes life into every Mazda.

Kimio Dojo, who is a member of Mazda’s Vehicle Body Production Department, has 24 years of experience in metal mold maintenance. Spotting almost invisible wear and tear in metal molds and reshaping the molds to its original shape using all kinds of tools are his responsibilities.

“Metal mold finishing requires abilities to see subtlest changes in mold (detection and restoration skills (welding, grinding and polishing capabilities). Comparing to a dentist, my job is to spot early symptoms of dental disorder by looking at an overall picture and treat the symptoms before they develop into a full disorder”, says Dojo.

Mazda’s challenge is to pass Dojo’s masterful skills to the next-generation of skilled experts. In the old days, it generally took 10 years to qualify as an expert, and another 10 years to acquire sophisticated finishing skills, and another 10 years to qualify as a “master”. Eiji Matsushima is currently working on a “master training system” to assist in this process. Dojo is helping recording his “masterful skills” inherited from his seniors in writing and in a video format.

“To me, the beauty of Mazda’s KODO Design lies in contrasts of light and shadow. You see that the reflection of scenery on car’s body is seamless and clear. To protect the design I never make a single compromise. I am 100% committed to maintaining beautifully sloping surfaces that are a part of a singular, continuous surface.”

Dojo’s passion and pride for his profession are evident from his own words.

Other Stories

Driving stories on the great & challenging roads and journeys

Stories about the craftsmanship and design evolution of Mazda

Visions and philosophies of Mazda engineers

The spirit of Mazda owners, collectors, clubs and aficionados around the world

Mazda brand heritage and history